Aluminum composite panel (ACP)

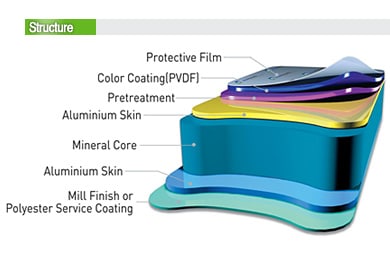

Aluminum Composite Panel (ACP), also known as ACM panel (Aluminum composite material panel) is flat sheet but can be bent, cut and punched easily. ACP is used as surface cladding material, or processed for 3D lettering. Lightweight, colorful, patterned, high precision, easy to clean, and limited to sound transmission and heat insulation. Composite aluminum plate is usually about 3 - 6 mm thick, assembled by 2 layers of aluminum, each layer is 0.5 mm thick, with the middle core made of polyethylene - a 3 mm thick flame retardant plastic. ACP includes two types: PVDF (outdoor aluminum cladding) and PET (indoor aluminum cladding)

ACP strenghts

- Various color choices

- Moisture resistance, heat insulation, soundproofing, high durability

- Easy in construction, can be bent according to dome, round column, angle curl

- Cost saving, high aesthetic efficiency

Variants of ACP

PVDF nanosheet

The nano aluminum composite panel is coated with a special structure that is resistant to dust.

Fireproof Aluminum composite panels

Fire retardant plastic is LDPE and HDPE which is blended with fireproof industrial materials to ensure specified fire resistance time before forming a flame.

Color choices: Fireproof Aluminum composite panel includes all color codes in the color scheme of standard ACP

With flame retardant properties, the fireproof aluminum plastic panel will be the choice for projects requiring high fire safety.

We Guarantee Successful Outsourcing

Best delivery performance, competitive pricing, better commercial terms, stable supplier base, control lead time

Effective and seamless workflow

With millions of parts delivered annually and serving more than 30 international customers, we are practicing the most advanced workflow to ensure the satisfaction of our customers and suppliers

- part shipped annually7mil

- Quality acceptance98%

Free consultation

Book an online meeting within 24 hours