Currently, the mechanical industry in Vietnam has made significant progress, demonstrating its active efforts to create leverage for other sectors. With still great potential, the mechanical industry promises to bring new breakthroughs in the future and is a “fertile” land to attract foreign enterprises to invest. In fact, many large foreign enterprises have set their expectations and trust when looking for metal processing partners in Vietnam.

The demand for manufacturing components for various machines is increasing day by day. For any business wishing to find a reputable outsourcing unit in Vietnam, from the need to purchase mechanical machinery, to the production of machine components such as bevel gears, then finding VNO will bring many outstanding benefits. Why is that so? Let’s find out in the following article.

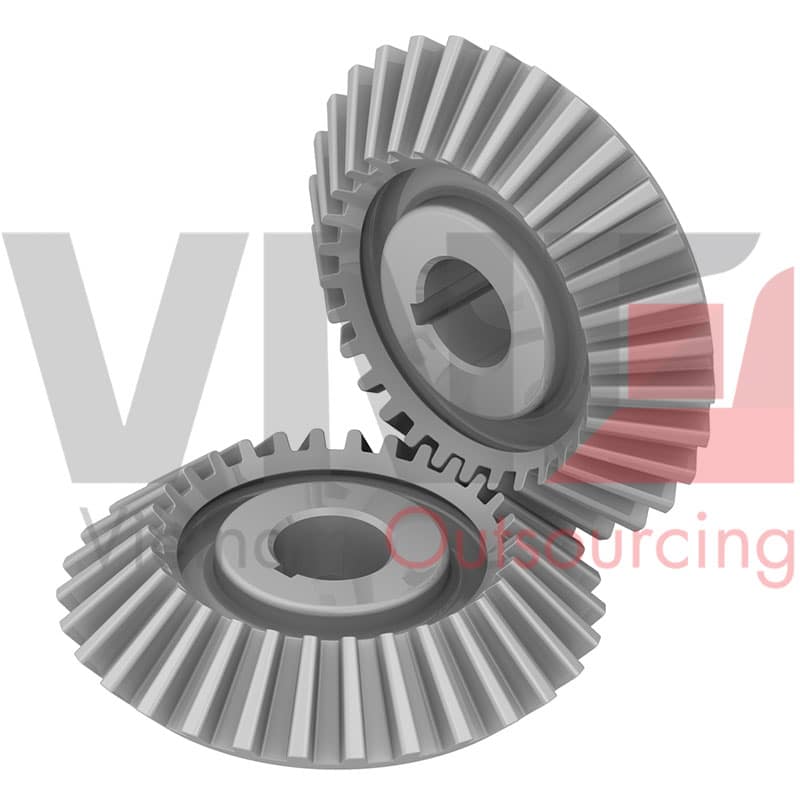

1. General information about bevel gears

Bevel gear is one of the components that play an essential role in mechanical machinery. This type of gear has the effect of helping two intersecting axes create motion. Essentially, gears play the role of transmitting signals in the perpendicular direction from one axis to another in a convenient and easy way. The application of gears is often used to manufacture speed reducers and reducers. The bevel gear is constructed on the bevel face, the teeth are cut along the conical surface. The size and modulus will vary considerably depending on the tooth’s length. At the top of the cone, the gear will be much smaller in size and modulus.

For example: When an Enterprise has a need to process bevel gears in Vietnam, the Enterprise will be consulted on materials to make gears. Reputable processing units will make careful selections based on basic requirements for evaluation, which can include:

- When installing gears on machines, how do they work? Based on temperature and environment, how can we assess the durability and heat resistance of gears?

- What is the capacity of that gear-mounted machinery system?

- Selection of gear materials should be in accordance with the criteria as well as the working conditions of the machine. This helps ensure the gears are durable for a long time, even when the machine is operating at high capacity.

- The choice of gear material depends on the machining method.

2. Classification of bevel gears

- Straight bevel gear: Straight bevel gear has the English name Straight Bevel Gear. Straight tooth pitches are used to transmit forces between perpendicular axes. With the characteristic of conical tooth pitches, elongated to the top, this type of gear is often used to transmit force between two intersecting axes. Straight bevel gears operating at high speeds and high loads are rated for increased accuracy.

- Helical bevel gear: This type of gear with teeth that are inclined and curved at an angle, which transmits force between two similar shafts. Gears will be in contact, transmitting movement slowly when operating. As a result, they have less vibration and quieter operation than straight bevel gears of similar size.

- Zerol-shaped bevel gear: This gear is composed of curved teeth, but the tooth head is straight, and the crown is along the circumference around the gear.

- Hypoid bevel gear: This type of gear with a hypoid-shaped surface and a large diameter gear. This type of gear has the advantage of long service life.

3. Advantages & Disadvantages of bevel gears

-

Advantage

-

- Bevel gears have a flexibly changeable operating angle, making them flexible during use.

- The working efficiency of bevel gears is very high, up to 90%, even in some cases higher than this number.

- Affordable production costs

- Using this type of gear helps reduce sliding friction; they have good durability and can withstand large forces

-

Defect

-

- The bevel gear needs to be correctly assembled with the corresponding shaft for smooth operation

- When operating at high speed will cause noise

4. Why should you choose a reputable unit to process bevel gears?

After distinguishing the types of bevel gears and choosing the right gear products for your machine application, you need to find a reputable processing unit. Because we cannot deny the importance of this type of gear for the operation of many types of machinery and equipment. The fact that businesses find a reputable mechanical processing unit will show that the unit focuses on investing in processing bevel gears. Prestigious units have invested in efficient gear processing machinery with high precision, ensuring the quality of gears. Advanced and modern machines are capable of automation, helping to shorten processing time and save costs for enterprises.

Bevel gears are important components in helping many machines operate smoothly. Businesses must choose an experienced outsourcing unit. Because machining this type of gear requires technique and is not simple. Bevel gears with outstanding advantages will be widely applied in many different industries.

As mentioned above, there are four distinct types of bevel gears with different characteristics. This gear type is becoming increasingly popular because it can be used in many fields. Depending on the purpose of use, the enterprise can consider and choose the appropriate bevel gear for processing requirements.

5. Why should you choose VNO as an intermediary when there is a need for mechanical processing in Vietnam?

- VNO has a mission to break down all barriers between international enterprises and prestigious mechanical processing units in Vietnam. VNO provides tailored sourcing, project management, logistics management and supply chain management services.

- VNO has many years of experience in becoming an intermediary that effectively supports businesses on many continents (such as Europe, America, etc.) to find a reputable mechanical processing unit that is present in Vietnam. Male. Businesses can rest assured because VNO can recommend the best outsourcing unit with competitive prices. The positive experiences from old customers are the most objective assessment when talking about the performance of VNO.

- VNO has 17 years of experience operating in the Chinese market of billions of people. Taking advantage of that, VNO applies the acquired experience to find and connect reputable outsourcing units in Vietnam. VNO has a management team from the West, providing seamless communication from the UK office, ready to support Businesses when problems arise.

6. Conclude

The demand for processing bevel gears in particular and the demand for mechanical processing in general of many foreign enterprises is increasing in Vietnam. Because Vietnam has all the advantages to develop strongly in this field. For foreign enterprises wishing to do mechanical processing in Vietnam, of course, finding reputable mechanical processing units is essential. VNO’s mission is to become a bridge between foreign enterprises and manufacturing plants in Vietnam in terms of mechanics. It is certain that VNO will maximize its prestige and strength to find the best and most suitable mechanical processing units for enterprises.