What is brazing aluminum

Brazing is a method of joining metals together using a filler material like solder, brazing rod, or other materials. It can be used to join metals that have different hardnesses. You need to apply heat and pressure to the joint to melt the filler material. When the filler material cools down, it solidifies and forms a strong bond between the two pieces of metal. The heat required depends on the type of metal you are working with. For example, if you were using aluminum, you would need about 400 degrees Fahrenheit. If you were using steel, you would need about 1,000 degrees Fahrenheit. There are many different types of joints you can weld. Some examples include but are not limited to: lap joints, edge joint welding, butt joints, and corners.

Brazing aluminum process

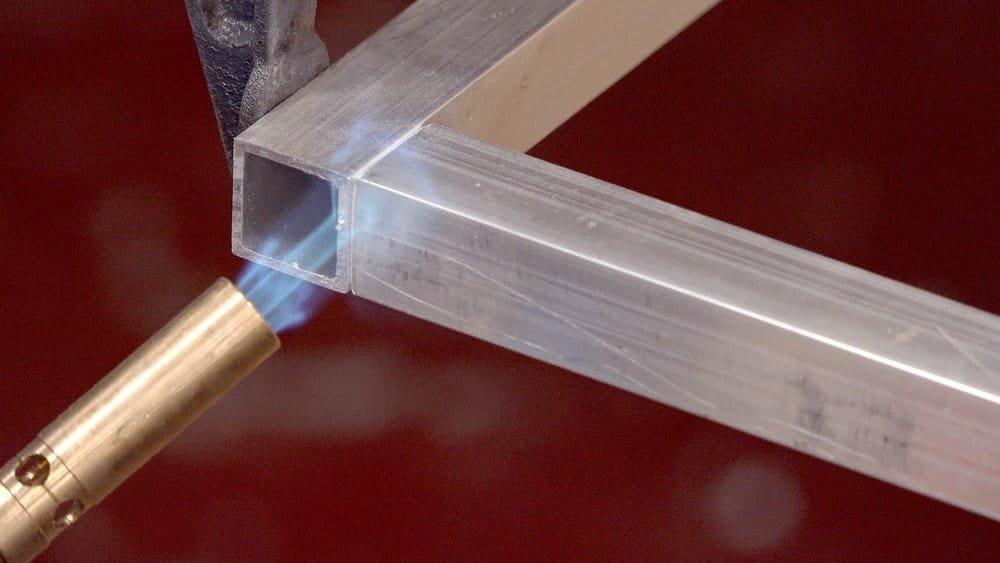

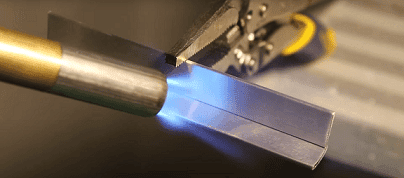

First, preheat the oven to 400 degrees F. Next, clean the surfaces of both pieces of metal using a wire brush and/ or steel wool soaked in copper solvents. Then, heat up the torch and start melting down the edges of the two pieces together. When the metal starts to flow, stop heating the torch and let the parts cool. Once the pieces have cooled down, remove them from the oven and place them back on the stove top. Use a propane torch to melt the rest of the joints. Once all the pieces have been joined, clean up the mess and move onto the next step.When you have completed this step, you will need to clean the excess flux off of the pieces of metal. If there is any left, continue to clean until it is completely gone. Once you have done this, you will need to begin the actual welding process. You will want to heat up the joint slowly, making sure that you maintain a constant temperature throughout the entire process

When you see the metal start to bubble, this is a sign that the flux has started to melt and coat the entire surface area. You will want to keep a close eye on the joint during this time, since you may need to adjust the heat accordingly. Continue to heat the joint until it turns red hot, at which point you will want to turn down the heat slightly and wait for the metal to cool before continuing.You will need an oven with a temperature range of about 500°F – 600°F and a torch that produces enough heat to melt aluminum. You should also have a supply of clean aluminum and flux. Aluminum is very reactive and will burn if exposed to air. To avoid this, you must keep the melted aluminum covered at all times. You may wish to wear protective gear like goggles and gloves when melting aluminum. Make sure to always check the temperature of the molten aluminum before adding more fuel. If you are using a torch, you should be careful not to let any sparks escape.

You also might want to know:

We Guarantee Successful Outsourcing

Best delivery performance, competitive pricing, better commercial terms, stable supplier base, control lead time

Effective and seamless workflow

With millions of parts delivered annually and serving more than 30 international customers, we are practicing the most advanced workflow to ensure the satisfaction of our customers and suppliers

-

part shipped annually7mil

-

Quality acceptance98%

Free consultation

Book an online meeting within 24 hours