CNC turning vs CNC milling

Turning and milling machining methods are two methods that use the same principle of cutting machining. Therefore, these two methods have some similar characteristics that many people easily confuse. Here are the differences between the two machining methods of milling and turning

Comparison

Definition

CNC Milling

The machining method of milling is a type of machining that cuts metal billets. The milling method differs from the convenience in that the movement is the rotation of the cutting tool as the tool. The remaining movement is the vertical tooling movement in such directions as vertical, horizontal, or vertical. During milling, the workpiece is clamped firmly on the machine table while the tool movement runs in all directions.

CNC Turning

Turning is a machining method of cutting metal billets that uses the rotation of the workpiece and the movement of the tool to create a cut. In the turning, the workpiece and cutting tool (knife) will be included.

Characteristic

– Characteristics of cutters: cutters used in milling usually include many cutting edges, providing very high cutting efficiency, especially when applied in-plane milling.

– Characteristics of the finished product after processing: after the metal product is processed, the surface usually has a gloss of level 4 – 6. The accuracy of the finished product is also level 2 – 8. Milling is applicable for the details are highly complex, and the metal sheets are more than 0.8mm thick.

– Features of milling machine: wide applicability, applicable to milling, boring, drilling, cutting, chamfering, or tapping … The rigidity of the milling machine is also much higher than that of a lathe at the same time. more stable. Applying high mechanization and automation, however, the cost of the milling machine is high, so the investment cost is expensive and the spare parts are relatively complicated.

– Main finished product usually has a rotating form such as a smooth shaft, stepping shaft, types of taper, thread, hole …

– High productivity, great versatility convenient

– High precision lathe machining, especially for fine turning.

– Turning machine: Easy to operate and operate, turning machine has many different sizes, so it can be applied to many different size products. For a long tape lathe, the firmness is not very high.

– The details with high complexity or turning on the plane will make it difficult to turn.

Applications

Machining on large and complex shapes. In addition, the milling technology can also be applied to plane, inclined surface, keyway types, common clear, complex or simple profiles. Milling also performs hole machining.

– Machining the part that can be shaped by the workpiece rotation.

– Machining surfaces for single axis, stepping shaft, types of cones, threads, holes, rotating profiles …

– Processing special surfaces using the attached jigs.

– Processing holes such as holes, non-holes, threaded, non-threaded or shaped holes

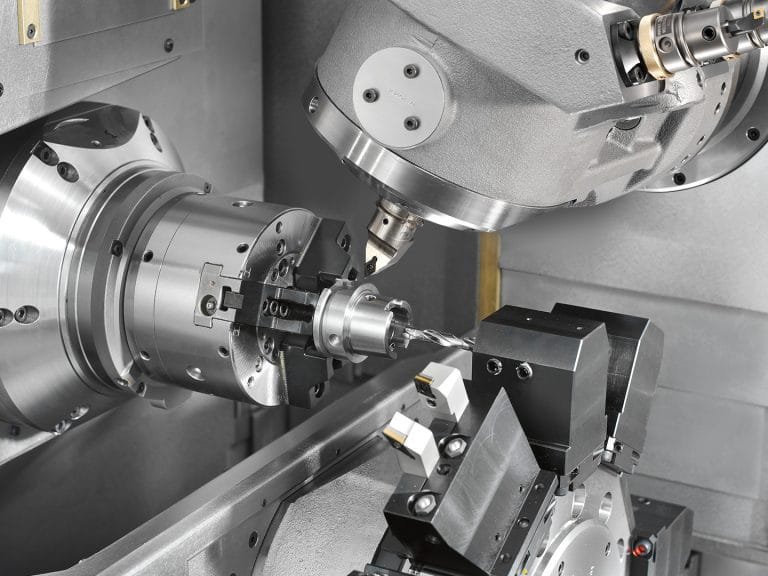

What is Mill - Turn?

This is a combination of two turning-milling operations on the same machine. They are a composite machine that uses the rotation of the tool and the rotation of the workpiece for machining. Mill-turn allows the user to machine more complex parts without switching the machining center and in much less time. This is the most suitable machining form for parts requiring both milling and turning.

You might also want to know:

We Guarantee Successful Outsourcing

Best delivery performance, competitive pricing, better commercial terms, stable supplier base, control lead time

Effective and seamless workflow

With millions of parts delivered annually and serving more than 30 international customers, we are practicing the most advanced workflow to ensure the satisfaction of our customers and suppliers

-

part shipped annually7mil

-

Quality acceptance98%

Free consultation

Book an online meeting within 24 hours