Unveiling the Backbone of Electronic Devices: Battery Housing

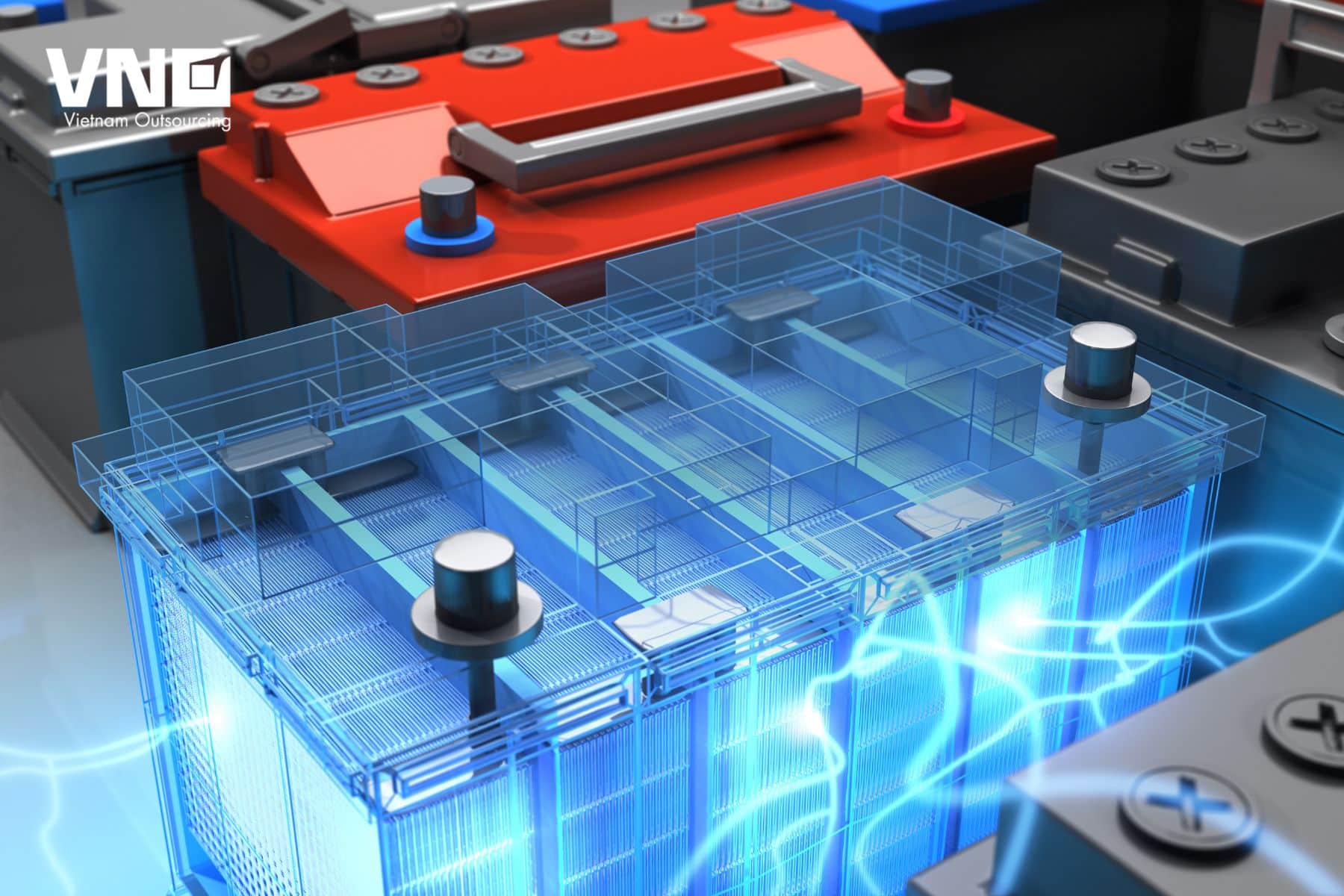

Imagine your smartphone without a reliable battery housing – a flimsy shell that can’t protect its delicate inner workings. Battery housing may seem like a mundane component, but it plays a crucial role in safeguarding the power source of our beloved gadgets.

It acts as a sturdy fortress that shields the intricate batteries from external factors, ensuring seamless functionality and longevity. From smartphones to laptops, electric cars to wearable tech, battery housing is the unsung hero that holds together our modern world of electronics.

Without durable and well-designed housing, these devices would be vulnerable to damage, jeopardizing their performance and safety. The significance of battery housing extends far beyond its physical presence; it is the invisible force that secures our digital lives.

The Power of Outsourcing: Enhancing Efficiency and Flexibility

In today’s globalized economy, outsourcing has become a strategic tool for businesses looking to optimize their operations and cut costs. When it comes to manufacturing components like battery housings for electronic devices, outsourcing offers a myriad of benefits.

By entrusting specialized tasks to external suppliers or manufacturers, companies can focus on their core competencies while leveraging expertise from around the world. Outsourcing battery housing production allows companies to tap into resources and capabilities that may not be available in-house.

This opens doors to cost savings through economies of scale, access to advanced technologies, and faster time-to-market for new products. Additionally, outsourcing provides flexibility in scaling production volumes up or down based on market demands, giving businesses agility in responding to changing industry landscapes.

Why Vietnam for Battery Housing Outsourcing?

Cost-effective labor and production costs

Vietnam has emerged as a prime destination for battery housing outsourcing due to its highly competitive labor and production costs. Compared to other manufacturing hubs, such as China or India, Vietnam offers a significant cost advantage without compromising on quality.

The lower wages in Vietnam translate to more affordable manufacturing expenses, making it an attractive option for businesses looking to optimize their production budgets. Moreover, the overall cost of doing business in Vietnam is relatively lower than in many other countries.

From real estate prices to utility costs, operating expenses in Vietnam are favorable for foreign investors seeking cost-effective solutions. This cost efficiency extends beyond labor and directly contributes to the overall competitiveness of the Vietnamese manufacturing industry on a global scale.

Skilled workforce and established manufacturing infrastructure

One of the key strengths of Vietnam’s manufacturing sector is its skilled workforce. With a strong emphasis on education and vocational training programs, Vietnamese workers are known for their dedication, precision, and adaptability.

The country boasts a large pool of talent with expertise in various industries, including electronics and engineering, making it an ideal choice for battery housing outsourcing. Furthermore, Vietnam has developed a robust manufacturing infrastructure over the years, supported by industrial zones and specialized economic zones that cater specifically to foreign investors.

These well-established facilities provide access to advanced technology, modern equipment, and streamlined logistics networks that enhance operational efficiency. Coupled with the skilled workforce, the existing manufacturing infrastructure in Vietnam offers a conducive environment for businesses seeking reliable and high-quality production capabilities.

Choosing the Right Partner in Vietnam

Researching Reputable Manufacturing Companies

When it comes to outsourcing battery housing production to Vietnam, one of the crucial steps is conducting thorough research on reputable manufacturing companies. It’s essential to delve into their track record, client testimonials, and industry reputation.

Look for companies with a proven history of delivering high-quality products and meeting deadlines consistently. Online reviews and industry forums can be valuable resources for gaining insights into the credibility and reliability of potential partners.

Visiting Facilities and Assessing Capabilities

Once you’ve identified a shortlist of manufacturing companies in Vietnam, the next step is to visit their facilities personally. Nothing beats seeing the operation firsthand to assess their capabilities accurately. Pay close attention to the equipment used, production processes, quality control measures in place, and overall cleanliness of the facilities.

Engage with key personnel to get a sense of their expertise and commitment to excellence. By physically inspecting the facilities, you can ensure they align with your quality standards and production requirements before making any commitments.

Ensuring Quality Control in Battery Housing Production

Implementing strict quality control measures

When it comes to manufacturing battery housings, ensuring top-notch quality is paramount. To achieve this, reputable companies in Vietnam implement stringent quality control measures right from the production line.

This includes thorough inspections at every stage of the manufacturing process to identify any potential issues or defects early on. By setting high standards and closely monitoring production, they can guarantee that only products meeting the specified criteria will make it to the final stages.

Conducting regular inspections and audits at the production site

Regular inspections and audits are key components of maintaining quality control in battery housing production. These proactive measures involve on-site visits by quality assurance teams to assess manufacturing processes, check for compliance with standards, and ensure adherence to safety protocols.

By conducting routine checks throughout the production cycle, any deviations from set guidelines can be identified promptly and rectified before they impact the overall product quality. This hands-on approach not only helps in detecting potential issues early but also fosters a culture of continuous improvement within the manufacturing facility.

Niche Subtopic: Environmental Sustainability Practices in Vietnamese Manufacturing

Overview of Eco-Friendly Initiatives in Vietnam’s Manufacturing Sector

When it comes to sustainability, Vietnam is making impressive strides in its manufacturing sector. Companies are increasingly implementing eco-friendly practices to reduce their environmental impact.

From energy-efficient production processes to waste recycling programs, the focus on sustainability is evident across the industry. Vietnamese manufacturers understand the importance of preserving the environment for future generations and are actively seeking ways to operate more sustainably.

Specific Examples of Sustainable Practices Adopted by Battery Housing Manufacturers

Battery housing manufacturers in Vietnam are leading by example when it comes to sustainability. Many companies have adopted practices such as using recycled materials in production, implementing water-saving technologies, and reducing carbon emissions through efficient transportation methods.

Some innovative manufacturers have even invested in renewable energy sources like solar power to fuel their operations. These sustainable initiatives not only benefit the environment but also contribute to cost savings and improved corporate social responsibility.

Rarely Known Detail: Cultural Etiquette Tips for Doing Business in Vietnam

Understanding Vietnamese Business Customs and Etiquette

In Vietnam, business is conducted with a strong emphasis on respect and hierarchy. It is essential to address your counterparts with proper titles and use formal language during meetings.

Building personal relationships before diving into business matters is crucial, as trust and rapport play a significant role in Vietnamese business culture. Understanding these customs will help you navigate the nuances of conducting successful business transactions in Vietnam.

Tips on Building Strong Relationships with Vietnamese Partners

Building strong relationships with Vietnamese partners requires patience, sincerity, and a willingness to invest time in getting to know them on a personal level. Engaging in small talk before discussing business matters shows that you value the relationship beyond just transactions.

Taking an interest in Vietnamese culture and traditions demonstrates your respect for their way of life. By fostering genuine connections based on mutual trust and understanding, you lay a solid foundation for fruitful partnerships.

Navigating Communication Styles and Decision-Making Processes

Communication styles in Vietnam tend to be indirect, with an emphasis on non-verbal cues such as body language and facial expressions. It’s essential to pay attention not only to what is said but also how it is communicated.

Decision-making processes may involve consensus-building rather than top-down directives, so be prepared for collaborative discussions where input from all team members is valued. By adapting your communication approach to align with Vietnamese cultural norms, you can enhance communication effectiveness and strengthen working relationships.

Conclusion & Future Outlook

Outsourcing battery housing production to Vietnam offers a myriad of benefits ranging from cost-effectiveness to access skilled labor force while contributing positively towards sustainable manufacturing practices. With a focus on eco-friendly initiatives gaining momentum within the industry and an understanding of cultural etiquette tips when doing business there can lead not only successful partnerships but also enriching experiences that transcend mere transactions. Embracing these opportunities for growth and innovation while respecting cultural nuances along the way opens doors for exciting possibilities within the evolving landscape of the Vietnamese manufacturing industry.