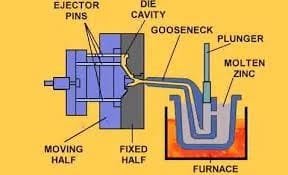

Hot chamber die casting machine

Hot-chamber die casting machine, which is very popular today, is the most widely used vertical type hot-chamber pressure machine

The plunger will press the metal vertically and the sprue is connected directly to the furnace

How does it work ?

The working principle of the hot-chamber pressure casting machine, also includes 4 stages, such as the cold-chamber pressure casting machine.

In the first stage: the mold is mounted on the machine, and the two halves of the mold are tightly closed by the clamping mechanism of the machine. At this time the metal is poured into the furnace.

Second stage: The pressing piston will press the liquid metal from the furnace into the mold, creating the shape of the casting detail.

Third stage: At this time, the dynamic half of the mold is opened thanks to the opening and closing mechanism, and at the same time the side code structure is drawn. At this time the casting is still on the half of the mold.

The fourth stage: The product push mechanism, will push the part out, after the product is pushed out, half of the mold is closed. At the same time, the pressing plunger moves to the top of the furnace, allowing it to be transferred to the next pressing process

You might also want to know:

We Guarantee Successful Outsourcing

Best delivery performance, competitive pricing, better commercial terms, stable supplier base, control lead time

Effective and seamless workflow

With millions of parts delivered annually and serving more than 30 international customers, we are practicing the most advanced workflow to ensure the satisfaction of our customers and suppliers

-

part shipped annually7mil

-

Quality acceptance98%

Free consultation

Book an online meeting within 24 hours