Introduction

Unlocking Efficiency Abroad

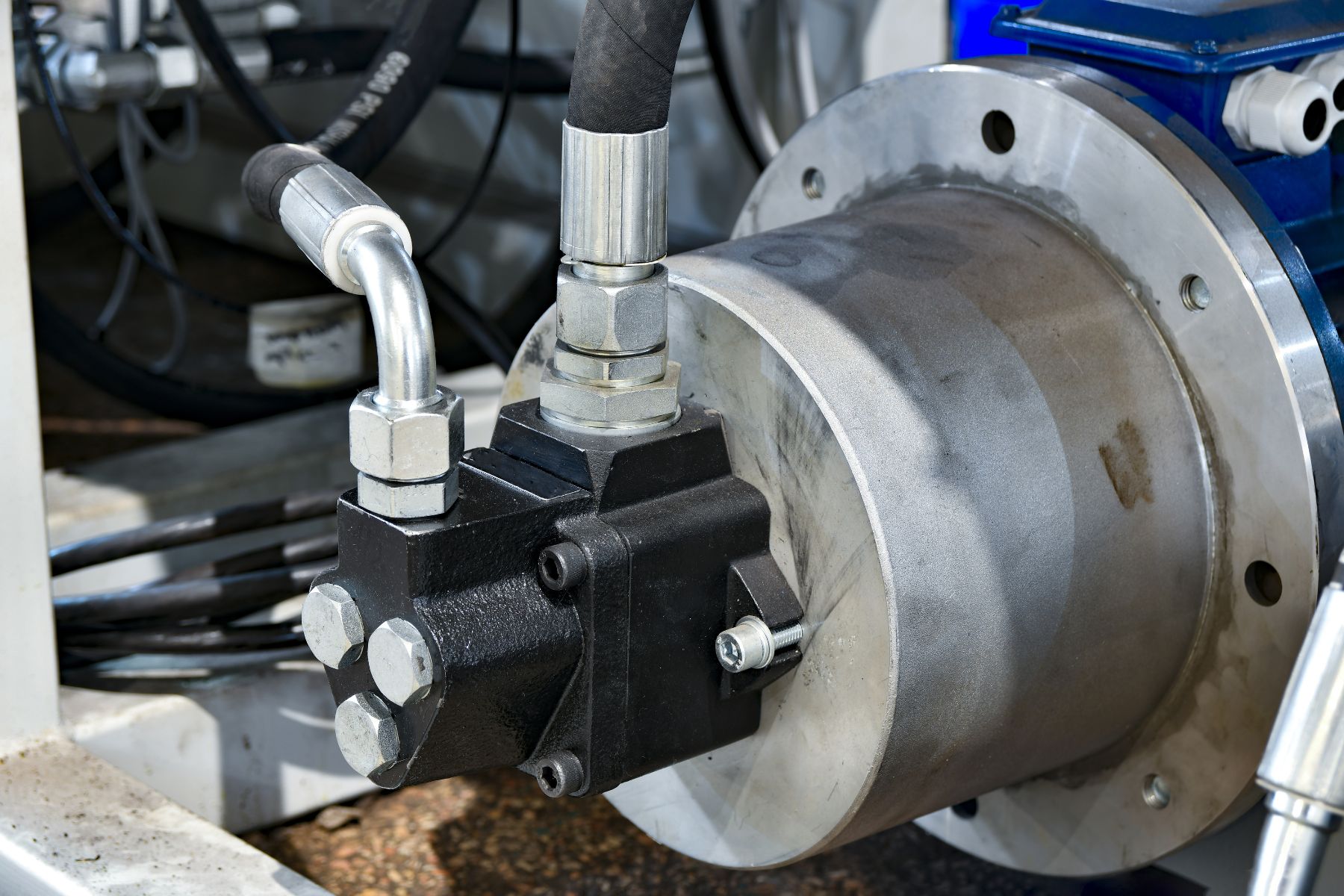

Outsourcing hydraulic pump production to Vietnam has become a game-changer for businesses looking to streamline their operations and maximize efficiency. With its rapidly growing manufacturing sector and skilled workforce, Vietnam has emerged as a top destination for companies seeking cost-effective solutions without compromising on quality. This strategic move not only allows businesses to focus on their core competencies but also opens up new opportunities for expansion and innovation.

The Vietnamese Advantage

When it comes to outsourcing, Vietnam offers a host of benefits that can significantly impact the bottom line. From competitive labor costs to a favorable business environment, the country provides a compelling proposition for companies looking to stay ahead in today’s competitive market landscape.

By tapping into Vietnam’s resources and expertise, businesses can achieve greater operational efficiency, reduce overhead expenses, and enhance overall productivity. In this article, we delve into the intricacies of outsourcing hydraulic pump production to Vietnam and explore how this decision can pave the way for long-term success in an ever-evolving global economy.

Why Vietnam?

Growing Manufacturing Sector in Vietnam

Vietnam has emerged as a powerhouse in the manufacturing industry, attracting businesses from around the world looking to capitalize on its dynamic market. The country’s manufacturing sector has experienced rapid growth in recent years, fueled by a combination of factors such as favorable trade agreements, infrastructure development, and a skilled workforce. With an emphasis on industrial diversification and technological advancements, Vietnam offers a fertile ground for companies seeking to outsource their production processes and streamline efficiency.

Skilled Workforce and Competitive Labor Costs

One of Vietnam’s key strengths lies in its abundant pool of skilled workers who are adept at handling advanced machinery and techniques required for manufacturing hydraulic pumps. The country boasts a young and highly educated workforce, with a strong focus on technical training programs that equip individuals with the necessary skills to meet industry demands.

Moreover, labor costs in Vietnam are significantly lower compared to many Western countries, making it an attractive destination for businesses aiming to reduce production expenses without compromising on quality. This combination of skilled personnel and cost-effective labor makes Vietnam an ideal choice for outsourcing hydraulic pump production.

Finding the Right Partner

Researching Reputable Manufacturers in Vietnam

When it comes to outsourcing your hydraulic pump production, finding the right manufacturing partner in Vietnam is crucial. Take the time to research and identify reputable manufacturers with a proven track record in producing high-quality hydraulic pumps.

Look for companies that have experience working with international clients and adhere to strict quality standards. Checking online reviews, industry certifications, and customer testimonials can give you valuable insights into the manufacturer’s reputation and reliability.

Evaluating Capabilities, Quality Standards, and Production Capacity

Once you’ve shortlisted potential manufacturing partners, it’s essential to evaluate their capabilities, quality standards, and production capacity. Visit their facilities if possible to see firsthand how they operate and ensure they have the necessary equipment and expertise to meet your requirements.

Discussing your specific needs regarding hydraulic pump design, materials, and production volumes is key to confirming that the manufacturer can deliver results that align with your expectations. Pay close attention to their quality control processes to ensure that every unit produced meets your standards.

Establishing Clear Communication Channels and Expectations

Effective communication is vital when partnering with a manufacturer in Vietnam for outsourcing your hydraulic pump production. Establish clear channels of communication from the outset to foster transparency and avoid misunderstandings down the line. Clearly outline your expectations regarding product specifications, delivery schedules, pricing agreements, and any other relevant details.

Regularly touch base with your manufacturing partner through emails, calls, or video conferences to stay updated on progress and address any issues promptly. Building a strong working relationship based on open communication can help ensure a successful outsourcing experience.

Streamlining Your Supply Chain for Success

Optimizing Shipping Routes and Lead Times

When it comes to outsourcing hydraulic pump production to Vietnam, one of the key factors to consider is optimizing shipping routes and lead times. Efficient logistics can significantly impact the overall efficiency of your operations. By carefully mapping out the most cost-effective and time-efficient shipping routes, you can minimize transportation costs and reduce delivery times.

Working closely with reliable logistics partners who have a strong understanding of the Vietnamese market can help streamline this process. To ensure that your products reach their destination in a timely manner, it’s essential to track lead times diligently.

From production facilities in Vietnam to distribution centers worldwide, keeping a close eye on lead times allows you to pinpoint potential bottlenecks in your supply chain and take proactive steps to address them. By leveraging data analytics and real-time tracking technologies, you can make informed decisions that optimize lead times and enhance the overall efficiency of your supply chain.

Mastering Inventory Management Strategies

Managing inventory levels effectively is crucial when outsourcing hydraulic pump production to Vietnam. Balancing stock levels to meet demand without overstocking or facing shortages requires a nuanced approach. Implementing just-in-time inventory practices can help minimize excess inventory holding costs while ensuring that you have an adequate supply of hydraulic pumps readily available.

Collaborating closely with your Vietnamese manufacturing partner to synchronize production schedules with demand forecasts can further optimize inventory management. Moreover, employing advanced inventory tracking systems enables you to monitor stock levels accurately and anticipate reorder points efficiently.

Leveraging data-driven insights allows you to fine-tune your inventory management strategies continuously based on demand fluctuations and market trends. By maintaining optimal inventory levels and strategically positioning stock across distribution channels, you can enhance operational efficiency while reducing storage costs associated with excess inventory.

Ensuring Top-Notch Quality Control

Implementing Rigorous Quality Assurance Protocols

When it comes to outsourcing your hydraulic pump production to Vietnam, maintaining high quality standards is crucial. This starts with implementing strict quality assurance protocols right from the beginning.

By clearly defining your quality requirements and expectations, you set the foundation for a successful partnership with the manufacturing facility in Vietnam. Whether it’s specifying material standards, performance metrics, or testing procedures, having clear guidelines in place ensures that every hydraulic pump produced meets your exacting standards.

Regular Inspections and Audits at the Production Facility

To uphold the quality of your hydraulic pumps, conducting regular inspections and audits at the production facility is essential. These on-site visits allow you to directly oversee the manufacturing process, identify any potential issues early on, and address them promptly.

By having a presence at the facility, you can ensure that all quality control measures are being followed diligently and that any deviations from standards are rectified swiftly. Building a relationship of trust with your outsourcing partner through these inspections not only helps maintain product quality but also fosters collaboration and continuous improvement initiatives.

Addressing Any Issues Promptly to Maintain High Standards

Despite meticulous planning and stringent protocols, unforeseen issues may arise during production. The key to preserving high standards is how effectively these issues are addressed. Communication is paramount in quickly resolving any quality-related concerns that may surface.

By maintaining open lines of dialogue with your manufacturing partner in Vietnam and working together to tackle challenges head-on, you demonstrate a commitment to excellence that will ultimately benefit both parties. Addressing issues promptly not only ensures product integrity but also builds a strong foundation for long-term success in outsourcing your hydraulic pump production.

Calculating Cost Efficiency

When considering outsourcing the production of hydraulic pumps to Vietnam, it’s crucial to evaluate the total cost savings compared to in-house production. While labor costs may be lower in Vietnam, you must factor in other expenses such as transportation, customs duties, and communication costs. Conduct a thorough analysis of all costs involved in both scenarios to get a comprehensive picture of potential savings.

Understanding Initial Setup Costs and Ongoing Expenses

Before diving into outsourcing your hydraulic pump production, take into account the initial setup costs required for establishing a partnership with a manufacturer in Vietnam. These may include expenses for travel, legal consultations, technology transfer, and setting up communication channels.

Additionally, consider ongoing expenses such as quality control measures, shipping fees, and any unforeseen operational costs. By having a clear understanding of these financial aspects from the outset, you can better plan your budget and avoid surprises down the road.

Establishing Transparent Pricing Agreements

To ensure a successful outsourcing arrangement that maximizes efficiency and minimizes financial risks, it is essential to establish transparent pricing agreements with your outsourcing partner in Vietnam. Clearly outline payment terms, pricing structures for various services or products provided by the manufacturer, as well as any potential additional charges that may arise during the production process. By fostering open communication regarding pricing details upfront, you can build trust with your partner and avoid misunderstandings or disputes later on.

Smooth Sailing with Project Management Best Practices

Setting Clear Project Milestones and Deadlines

When it comes to outsourcing your hydraulic pump production to Vietnam, having crystal-clear project milestones and deadlines is key. Break down your project into smaller, manageable tasks and set specific goals for each phase.

By establishing these milestones, you can track progress effectively and ensure that everything stays on schedule. Whether it’s finalizing design specifications or approving the first prototype, having these checkpoints in place will keep everyone aligned towards the ultimate goal of maximizing efficiency.

Assigning Dedicated Team Members to Oversee the Outsourcing Process

Assigning dedicated team members to oversee the outsourcing process is like having navigators on a ship – they guide you through the waters of production smoothly. These individuals should have a deep understanding of both your company’s needs and the intricacies of outsourcing to Vietnam.

By entrusting capable hands with this responsibility, you can rest assured that every detail is being handled with care. Their role is not just about monitoring progress but also fostering communication between your company and the manufacturing partner in Vietnam.

Sustainability Initiatives & Social Responsibility Efforts

Ensuring Ethical Labor Practices

When outsourcing production to Vietnam, it’s crucial to ensure that ethical labor practices are maintained at the manufacturing facility. This means guaranteeing fair wages, safe working conditions, and reasonable working hours for all employees.

By partnering with manufacturers who prioritize the well-being of their workers, you not only contribute to a more sustainable and responsible supply chain but also uphold your company’s values and reputation. Conduct regular audits and inspections to monitor compliance with labor laws and ethical standards.

Implementing Environmentally Friendly Production Methods

In today’s environmentally conscious world, it’s essential to consider the environmental impact of production processes. When outsourcing hydraulic pump manufacturing to Vietnam, look for partners that implement environmentally friendly practices such as recycling waste materials, reducing energy consumption, and using eco-friendly materials where possible.

By adopting sustainable production methods, you can minimize your carbon footprint and contribute to global efforts towards a greener future. Supporting manufacturers who prioritize sustainability not only benefits the environment but also aligns with consumers’ growing preference for eco-conscious businesses.

Supporting Local Communities through CSR Programs

Corporate social responsibility (CSR) programs play a significant role in making a positive impact on local communities. When outsourcing hydraulic pump production to Vietnam, consider implementing CSR initiatives that benefit the local population. This could involve investing in education programs, supporting healthcare initiatives, or contributing to community development projects.

By engaging with local communities through meaningful partnerships and initiatives, you not only fulfill your social responsibility but also foster goodwill among stakeholders. Supporting local causes demonstrates a commitment to making a difference beyond business profits and contributes to building a sustainable future for all involved parties.

Conclusion

Outsourcing hydraulic pump production to Vietnam can be a game-changer for businesses looking to boost efficiency and cut costs without sacrificing quality. By tapping into Vietnam’s growing manufacturing sector, skilled workforce, and favorable business environment, companies can achieve remarkable results and stay ahead of the competition.

In conclusion, collaborating with Vietnam Outsourcing Pte Ltd (VNO) presents a compelling opportunity for businesses seeking reliable partners in the procurement of outsourced hydraulic pump manufacturing services in Vietnam. With its specialized expertise in procuring proprietary metal components and a strong track record of excellence, VNO stands out as a trusted partner capable of meeting the diverse needs of clients across various industries.

VNO’s global sales support network in Singapore and an engineering team stationed in the UK, China, and Vietnam ensure seamless communication and coordination throughout the outsourcing process. This global presence allows VNO to serve clients worldwide efficiently, providing tailored solutions to meet their specific requirements.

Furthermore, VNO’s impressive performance metrics underscore its commitment to quality and reliability. With over 20 years of experience in China and 5 years of successful operation in Vietnam, VNO has established itself as a high-performance supplier with an exceptional reputation for quality acceptance and on-time delivery.

By partnering with VNO, businesses can benefit from its extensive industry knowledge, robust supply chain management, and unwavering dedication to customer satisfaction. Whether it’s procuring hydraulic pump components or any other metal components, VNO’s proven expertise and track record make it the ideal partner for businesses seeking reliable outsourcing solutions in Vietnam.

In summary, collaborating with VNO not only ensures access to high-quality outsourced hydraulic pump manufacturing services but also provides peace of mind knowing that your sourcing needs are in capable hands. With VNO as your partner, you can navigate the complexities of outsourcing with confidence and focus on driving business growth and success in the dynamic marketplace.