Vietnam’s Die Casting Industry in 2025

Over the past 25 years, Vietnam’s mechanical processing industry has grown into a national spearhead sector. Continuous research, innovation, and investment have pushed the industry forward. Die casting, in particular, now plays a central role in shaping growth. As a result, it provides the foundation for agriculture, fisheries, forestry, and services. Today, die casting not only meets domestic demand but also opens the door to export markets.

The government supports this momentum with new policies. Authorities encourage investment in infrastructure and supporting industries. At the same time, companies modernize equipment, adopt digital technology, and improve design efficiency. Therefore, the industry aims to reach 21% of the country’s industrial output and meet half of domestic demand in the near future.

Limitations

Die casting also has some drawbacks. Molds are expensive, as they require special heat-resistant steel and precise machining. The size of the casting is limited by machine capacity, which restricts very large parts. In addition, die casting works best with alloys such as aluminum, zinc, copper, and magnesium, but cannot be applied to steel or cast iron.

Engineers must also consider performance trade-offs. For example, die cast products may show reduced toughness under heavy impact or require multiple molds for varied designs. Despite these limitations, the advantages still outweigh the drawbacks in most applications.

Metals Commonly Used in Die Casting

Aluminum: Lightweight and corrosion-resistant, widely used in automotive and aerospace. To improve strength, aluminum is often alloyed with copper or silicon.

Copper Alloys: Excellent corrosion resistance and conductivity, commonly used in plumbing fixtures and electrical components.

Zinc: Offers high precision, easy casting at lower temperatures, and long mold life. Perfect for electronics and decorative hardware.

Magnesium: Very light yet strong, providing excellent dimensional accuracy for aerospace and high-performance products.

Choosing the right alloy depends on the product’s function, required durability, and cost. For instance, zinc offers long life and high durability, making it suitable for parts with extended operating cycles.

Die Casting in Vietnam Today

Vietnam die casting suppliers are increasingly recognized as reliable global suppliers. They combine modern high-pressure casting technology with automated production lines and closed-loop systems—from melting raw materials to delivering finished products. Pressure casting products such as side covers and arms are already exported worldwide, proving Vietnam’s competitiveness.

The advantage of die casting in Vietnam lies not only in the process itself but also in the country’s readiness to invest in modern technology and skilled labor. With automation, improved management, and compliance with international standards, Vietnam is positioned to become a leading die casting hub in Asia.

What is Pressure Casting Technology?

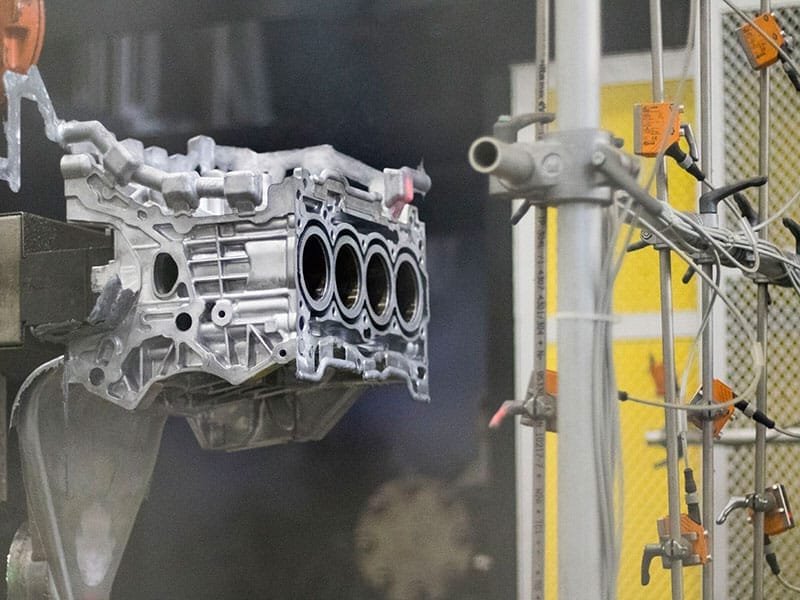

Pressure casting is one of the most advanced manufacturing methods. Engineers inject molten metal into a steel mold at high pressure. This process creates precise parts with excellent surface quality. Moreover, the cycle is short, and the steps are simple. Because of these advantages, pressure casting now accounts for the largest share among casting methods.

In Vietnam, factories use automated machines to perform pressure casting. These systems reduce manual work, improve consistency, and boost productivity. Consequently, pressure casting has become a powerful tool for mass production.

Advantage of Die Casting

Main Advantages

The advantage of die casting lies in its unique mix of speed, precision, and durability.

- It delivers accurate parts with smooth surfaces.

- It produces thin walls under 1 mm.

- It ensures strong, dense structures due to fast cooling.

- It supports automation, which lowers labor needs.

- It achieves much higher productivity than traditional casting.

- It reuses molds many times, reducing long-term costs.

- It makes stronger parts compared to plastic injection.

Together, these benefits make die casting ideal for automotive, electronics, and aerospace. In addition, the process provides consistency across high-volume production.

Limitations

However, die casting is not without challenges. Molds are expensive because they need heat-resistant steel and precise machining. Machine capacity limits the size of castings. In addition, the process only works with alloys such as aluminum, zinc, copper, and magnesium—not steel or cast iron.

Engineers must also consider durability and flexibility. For example, large impacts may reduce toughness, and different designs require separate molds. Even with these drawbacks, the advantage of die casting usually outweighs the limitations in industrial use.

Metals Commonly Used in Die Casting

Different alloys bring different strengths to the process.

- Aluminum is lightweight and corrosion-resistant. It is common in automotive and aerospace. To avoid cracking, manufacturers often mix it with copper or silicon.

- Copper alloys resist corrosion and conduct electricity well. They are popular for plumbing and electrical components.

- Zinc melts at low temperatures, allowing precise and durable parts. It is suitable for electronics and decorative products.

- Magnesium is extremely light but strong, offering high accuracy in aerospace and electronics.

Therefore, choosing the right alloy depends on function, durability needs, and cost targets.

Die Casting in Vietnam Today

Vietnamese factories now compete globally. They invest in modern high-pressure casting systems, automation, and closed production lines. As a result, they can deliver parts from raw material to finished product efficiently. Export products such as side covers and housings confirm Vietnam’s credibility in the world market.

You might also want to read more about Centrifugal casting

The real advantage of die casting in Vietnam comes from the combination of technology and people. Companies adopt Industry 4.0 practices, improve management, and comply with ISO and international standards. Consequently, Vietnam is becoming one of Asia’s most reliable die casting hubs.