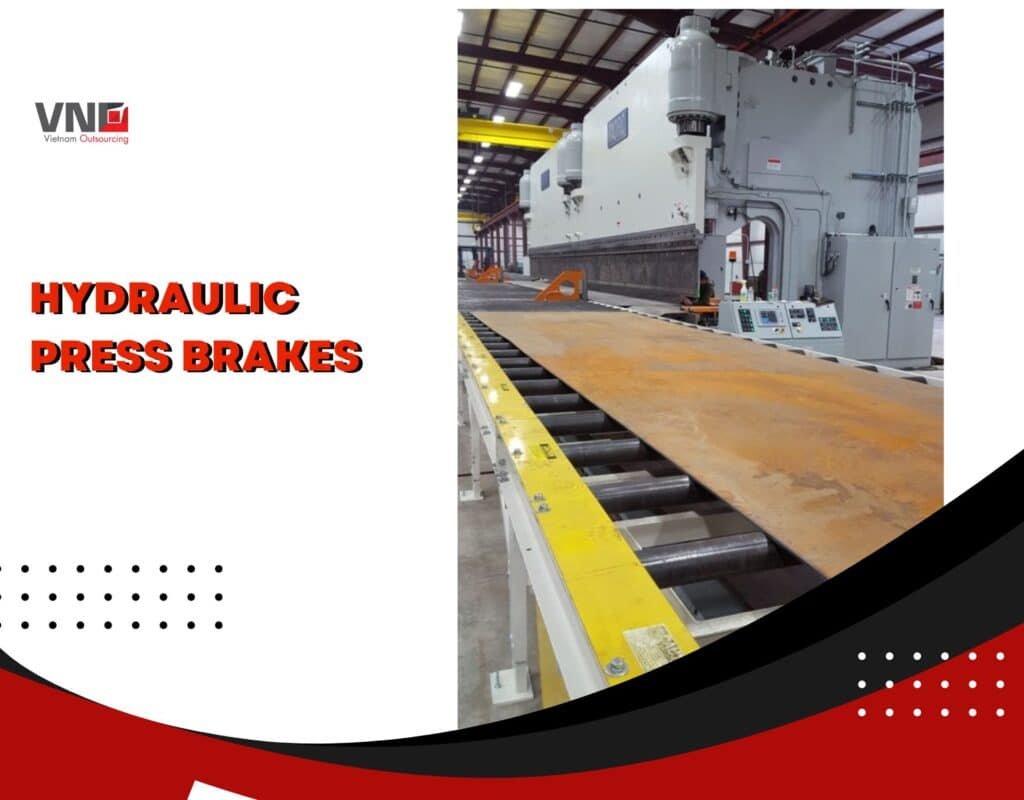

Overview of Hydraulic Press Brakes

Hydraulic Press Brakes are essential machines in modern manufacturing, designed to bend sheet metal and plate materials with precision. They use hydraulic cylinders to apply pressure through a punch-and-die system, shaping metal into exact angles and forms. Moreover, their strong frames and high load capacities make them suitable for both light and heavy-duty tasks. Capacities typically range from 30 tons to more than 2000 tons.

The global market is also expanding. For example, in 2023 it was valued at $4.5 billion and is projected to grow at a CAGR of 5.6% through 2028. This growth reflects the increasing demand for accurate bending solutions across industries worldwide.

Key Applications Across Industries

Metalworking and Fabrication

In metalworking, industrial press brakes help produce machinery parts, structural components, and custom fabrications. Because they handle many materials and thicknesses, they are widely used in both small workshops and large factories. For example, machines with 1500-ton capacities support large-scale projects.

Automotive Manufacturing

The automotive industry relies heavily on hydraulic bending machines for chassis, panels, and brackets. Since manufacturers often need high-volume production, advanced systems capable of 2000 tons of force ensure parts meet strict quality standards.

Construction Industry

In construction, press brakes create beams, columns, and supports. Their precision ensures components fit together correctly and perform reliably. As a result, machines exceeding 1000 tons are common in large-scale building projects.

Aerospace Production

The aerospace sector demands exact tolerances for fuselage panels, support structures, and engine components. Consequently, press brake machines used here often include advanced controls and automation to improve both accuracy and efficiency.

Why Source Press Brakes from Vietnam?

You might also want to know about Hydraulic Shearing Press

Precision and Reliability

Vietnamese suppliers are recognized for accuracy and durability. In fact, many achieve tolerances within ±0.1 mm, ensuring consistent performance across applications.

Cost Advantages

Because production costs in Vietnam are lower, companies can save up to 30% compared to sourcing from other regions. This cost-effectiveness makes Vietnam a strategic choice for global buyers.

Customization Options

In addition, manufacturers in Vietnam offer flexible solutions. They can adjust bending capacities, modify die designs, and add specialized features. This customization ensures machines fit seamlessly into diverse operations.

International Standards

Most suppliers also comply with ISO 9001 for quality management and ISO 14001 for environmental responsibility. Therefore, buyers can be confident that their machines meet global standards.

Technical Expertise and Support

Vietnamese producers provide full technical support, including consultation, installation, and after-sales service. As a result, clients benefit from better efficiency and longer machine lifespans.

Advanced Manufacturing Capabilities

Factories in Vietnam use CNC machining, robotics, and precision testing. Consequently, they produce high-performance bending machines with features that match global innovations.

Conclusion

Hydraulic Press Brakes remain indispensable in industries such as metalworking, automotive, construction, and aerospace. They combine strength, precision, and adaptability to meet the demands of modern production. Moreover, sourcing from Vietnam offers cost savings, customization, and adherence to international standards.

Looking for reliable Hydraulic Press Brakes? Partner with Vietnam Outsourcing (VNO) today for precision-engineered solutions tailored to your business needs.