How to cut down costs on your CNC projects

Introduction

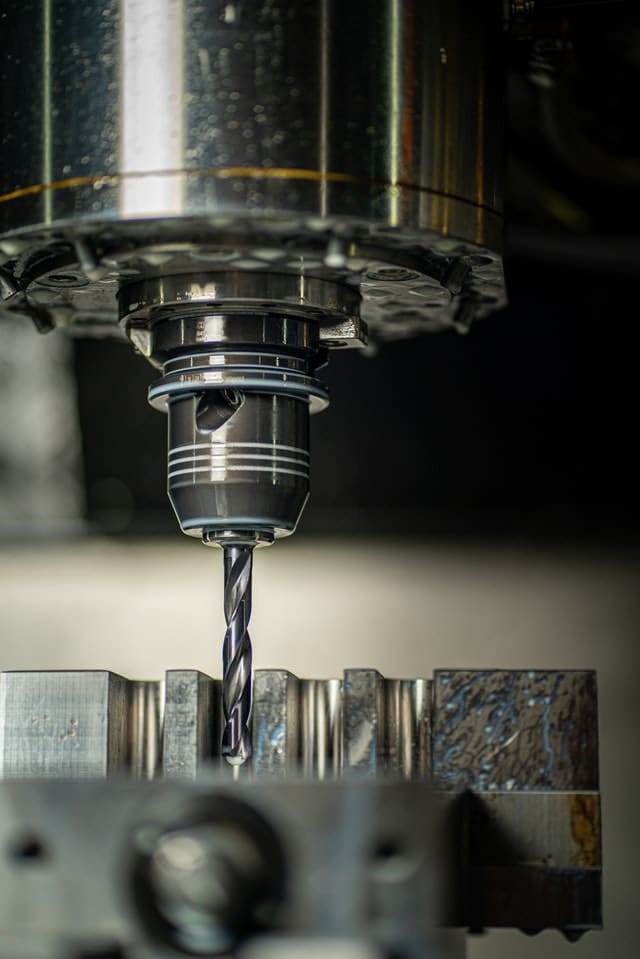

CNC milling and machining are powerful manufacturing methods, but they are rarely cheap. Without careful planning, CNC costs can rise quickly, putting pressure on budgets and reducing profit margins. However, by identifying the key factors that influence costs, manufacturers and buyers can minimize unnecessary expenses while maintaining high quality.

In this article, we explore what drives high CNC costs and provide practical tips to cut down CNC cost. We also highlight how sourcing from CNC costs in Vietnam can help international buyers achieve both affordability and efficiency.

1. Choose Raw Materials Wisely

Material selection is one of the biggest contributors to overall CNC costs. Premium alloys or exotic metals often cost more than the machining process itself.

-

For prototypes: use lower-cost materials that still replicate the mechanical properties needed for testing.

-

For short production runs: invest in higher-quality materials to ensure performance and reduce rework.

By aligning material choice with project goals, you can avoid overspending while still meeting functional requirements.

2. Optimize Setups to Reduce Downtime

Every time a CNC machine stops for a setup change, costs accumulate. To cut down CNC cost, minimize the number of setups needed per part.

-

Aim for single setups where possible.

-

For complex parts, keep setups under six to maintain efficiency.

The less time spent on machine downtime, the more productive hours you gain for actual machining. In addition, planning the CNC process in advance ensures smoother operations and lower expenses.

3. Looser Tolerances Lower Costs

The tighter the tolerance, the higher the CNC costs. Precision requires extra machining time, more tool wear, and higher scrap risk if specifications are missed.

-

Stick to standard tolerances when high precision is unnecessary.

-

Use identical dimensions for multiple features (e.g., holes) to reduce tool changes.

-

Avoid overcomplicated designs that add unnecessary costs.

In short, relax tolerances where possible to achieve significant savings without compromising function.

4. Watch Out for NRE Costs

Non-recurring engineering (NRE) costs are one-time expenses tied to design, programming, or tooling for a CNC project. They can be substantial, especially for large-scale production.

To manage them:

-

Address NRE requirements early in the design phase.

-

Reuse existing tooling or fixtures where possible.

-

Spread NRE costs across larger production runs to offset the impact.

By planning ahead, you reduce the time it takes for projects to become profitable.

5. Why CNC Costs in Vietnam Are Competitive

Global buyers increasingly turn to Vietnam because of the country’s strong combination of quality and affordability. Compared with China, Vietnam offers:

-

20–30% lower machining costs

-

Skilled engineers experienced in CNC milling, turning, and precision machining components

-

Compliance with ISO and automotive standards such as PPAP and FAI

For companies looking to cut down CNC cost, Vietnam presents a reliable option that balances cost efficiency with international quality standards.

Conclusion

Managing CNC costs requires a strategic approach that combines smart material choices, efficient setups, realistic tolerances, and careful planning for NRE expenses. Above all, reviewing project requirements early and aligning them with supplier capabilities ensures cost-optimized results.

For international buyers, outsourcing to Vietnam provides additional advantages, as CNC costs in Vietnam are highly competitive without sacrificing quality. See more about CNC machining trends 2025

Looking to save on your next CNC project? Contact Vietnam Outsourcing (VNO) today to connect with certified suppliers and achieve world-class machining at cost-effective rates.