Keep Delivering

- no 1902, A3 office, EcoLife building, To Huu Str, Hanoi, Vietnam

- info@vnoutsourcing.com

- +84 9 7979 6222

Green

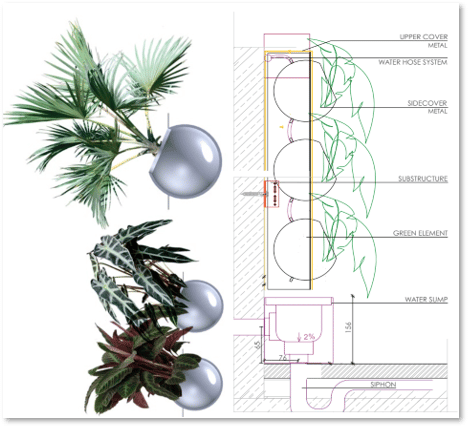

Green Urban Life is an interdisciplinary team of the sections of architecture, art, botany and technology, which plan and realize projects with green on and in buildings.

- Stainless steel – sheet metal forming which include:

Deep drawn metal stamping for large sphere D200mm & 300 mm. Laser cutting, welding and assembly. - Automatic watering solution

Vietnam Outsourcing (VNO) provided support from design verification, pre-production sampling, mass production, order fulfilment and delivery on time.

II. Process

III. Challenges

Deformation

Deformation defect during stamping is a very common type and requires experienced engineers to handle it effectively to ensure product quality is in accordance with customer requirements.

Scratched

Standardising engineering operations to significantly reduce product scratches is a must for machine operators in our factory

Stress marks

Stress fracture from stamping is a principle phenomenon and we can handle it with 15 years of experience of our highly specialised in stamping engineers.

Iv. our solution

DEFORMATION

SCRATCHED

Choose the most appropriate stainless-steel material: in austenitic stainless steel, the commonly used materials are 1Cr18Ni9Ti and 0Cr18Ni9Ti. During drawing, 1Cr18Ni9Ti is more stable than 0Cr18Ni9Ti and has good cracking resistance or SUS304Cu grade which has a 0.7-3.5% Copper content, which will aid the forming /stamping process.

STRESS MARKS

Use lubricant dry coating materials on the surface of die (main ingredients include nitride cotton, oleic alkyd resin and plasticizer, pressure agent material, etc.) to reduce the friction resistance between the material and the surface of the die during the forming process, it makes the material flow more easily from the deformation zone to the transit zone.

The dry film of the lubricant can separate the die from the blank materials, thus preventing the surface from scratching the parts and bonding of the mold, this way it improves the surface quality and the yield of good parts.

V.Summary

We would like to further expand our cooperation, because we are also

planning to establish the ideas and products of Green urban Life on the Asian market.

We think Hanoi could be a very good starting point.

~ Johannes Leitner ~

We Guarantee Successful Outsourcing

Best delivery performance, competitive pricing, better commercial terms, stable supplier base, control lead time

Effective and seamless workflow

With millions of parts delivered annually and serving more than 30 international customers, we are practicing the most advanced workflow to ensure the satisfaction of our customers and suppliers

-

part shipped annually7mil

-

Quality acceptance98%

Free consultation

Book an online meeting within 24 hours