Keep Delivering

- no 1902, A3 office, EcoLife building, To Huu Str, Hanoi, Vietnam

- info@vnoutsourcing.com

- +84 9 7979 6222

I. Overview

The customer is a UK-based company specializing in supplying products in the field of ammunition packaging. Their objective is to expand into the Vietnamese market to diversify their supply sources due to geopolitical influences.

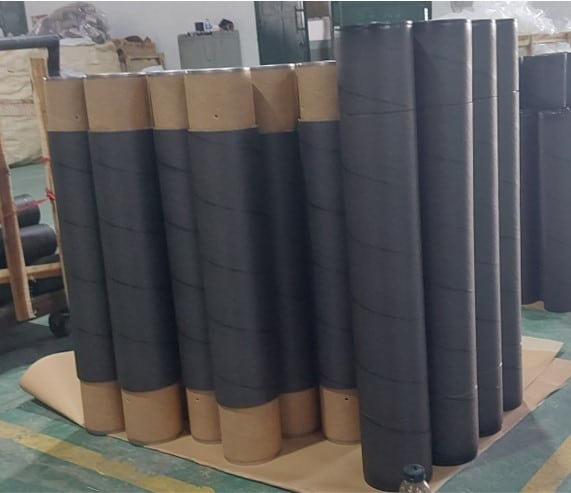

The FIBER TUBE product is a specific type of paper tube component, a part of the customer’s packaging product supply chain. It is a product with very strict requirements that comply with MIL standards.

VNO has collaborated with this supplier, working together to develop and refine the manufacturing technology of the product to best suit the machinery and existing technology conditions, upgrading management capabilities, and understanding of MIL standards. The project has been successfully implemented within the appropriate timeframe.

II. Main process

III. Detail process

Step 101

Qualified 100% IQC Material Inspection (Inspection level Importance ) Unqualification Review & Disposition

Step 2 (PQC)02

Kraft, aluminum foil, polycoat, polylaminate, polyvinylaxetate and asphalt glues – Split to small dims

Step 3 (PQC)03

Winding – following to each construction requirement of fiber tube and drying

Step 4 (PQC)04

Punching and bending mold metal subcomponents – Injection mold plastic

Step 5 (PQC)05

Assembly

Step 6 (PQC)06

Qualified FAT Inspection

Step 707

Write series number on out box & packing

III. Challenges

High-level management system

The product ordered by VNO with high requirements to meet MIL standards poses a challenge: the awareness and competence of all factory staff aim for a high-level management system. Considering the actual conditions of machinery and equipment at the supplier during production: Production technology and equipment management do not meet MIL standards. There is a shortage of skilled labor. The supplier is not accustomed to the stringent quality requirements and features of the product. Therefore, during the product development process, we worked with the supplier's engineers for three months before receiving the first prototype.

IV. Summary

Through the collaborative effort and time spent working together, we have successfully addressed the changing issues and selected technologies suitable for the current conditions of the supplier, resulting in the creation of a finished product that meets the customer’s requirements.

We Guarantee Successful Outsourcing

Best delivery performance, competitive pricing, better commercial terms, stable supplier base, control lead time

Effective and seamless workflow

With millions of parts delivered annually and serving more than 30 international customers, we are practicing the most advanced workflow to ensure the satisfaction of our customers and suppliers

-

part shipped annually7mil

-

Quality acceptance98%

Free consultation

Book an online meeting within 24 hours