- September 11, 2025

- Daniel Pham

Guard Rail Outsourcing: Why Vietnam is the Right Choice for Global Buyers

Table of Contents

Introduction

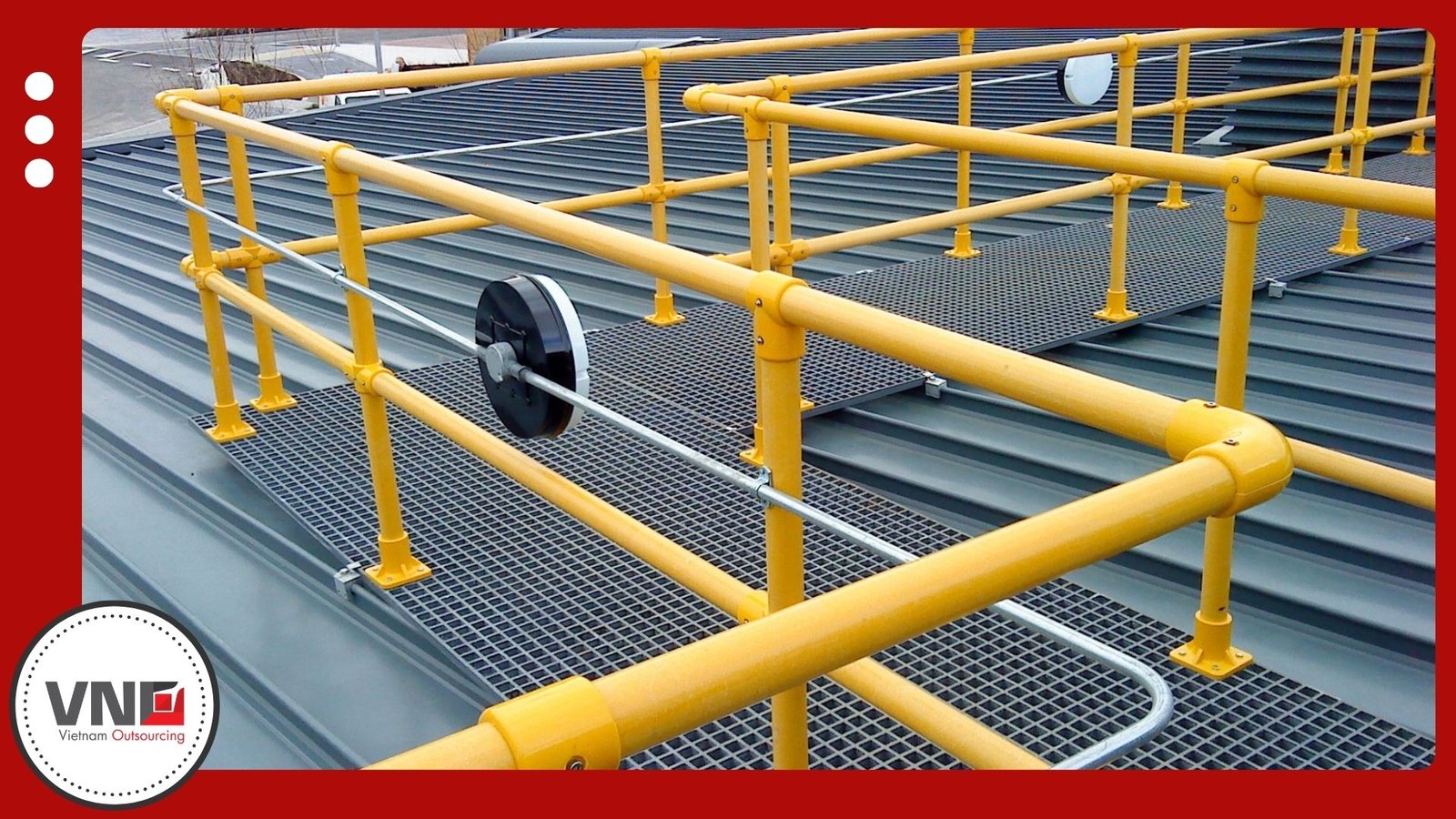

As global infrastructure projects continue to grow, the demand for safety components such as guard rails is increasing. Guard Rail Outsourcing has become a practical solution for governments, contractors, and infrastructure companies that want to balance cost efficiency with international safety standards. By choosing the right partner, businesses can secure reliable guard rail systems while reducing production and logistics expenses.

With its expanding manufacturing sector, Vietnam guard rail manufacturing is gaining recognition worldwide. Vietnamese suppliers combine modern technology, competitive pricing, and strict quality standards, making Vietnam a top destination for outsourcing guard rail production.

Technology in Guard Rail Manufacturing

Guard rails are essential for road safety, designed to absorb impact and protect vehicles and pedestrians. To meet global safety requirements, manufacturers rely on advanced technologies such as:

- Hot-dip galvanizing: Ensures corrosion resistance and long-term durability.

- High-precision roll forming machines: Produce W-beams, Thrie-beams, and customized profiles consistently.

- CNC punching and sheet metal cutting systems: Guarantee uniform holes and fittings for easy installation.

- Automated welding technology: Enhances structural integrity and reduces human error.

- Surface treatments and coatings: Improve weather resistance and extend product life.

Vietnamese factories have invested heavily in these technologies, allowing them to deliver products that meet U.S., EU, and Asian road safety standards.

Quality Control in Guard Rail Outsourcing

Because guard rails play a critical role in road safety, quality control is paramount. Leading Vietnam Guard Rail suppliers implement strict inspection protocols, including:

- ISO 9001-certified processes to ensure consistent production quality.

- Material testing for steel grades, tensile strength, and coating thickness.

- Impact and crash testing in compliance with ASTM, EN 1317, or AASHTO standards.

- Dimensional inspections for accurate profiles and hole placement.

- Batch traceability for documentation and accountability.

These practices guarantee that outsourced guard rails from Vietnam meet both international regulations and customer-specific requirements.

Choosing the Right Partner

Selecting the right supplier is key to successful guard rail outsourcing. Buyers should evaluate partners based on:

- Technical capability – Access to modern machinery and production capacity for large projects.

- Certifications and compliance – Ability to meet ASTM, EN, or AASHTO standards.

- Experience – Proven track record with infrastructure projects across different regions.

- Flexibility – Capability to produce both standard guard rails and custom designs.

- After-sales support – Commitment to logistics, installation guidance, and warranty services.

Working with a supplier that meets these criteria reduces risk and ensures long-term collaboration.

Why Vietnam for Guard Rail Outsourcing?

Vietnam has quickly become a trusted hub for safety equipment, metal forming products and construction components. The advantages of Vietnam guard rail manufacturing include:

- Competitive pricing: Lower labor costs compared to China and India, while maintaining high production standards.

- Modern infrastructure: Factories equipped with galvanizing lines, roll forming machines, and CNC systems.

- Young, skilled workforce: Engineers and technicians trained to operate advanced machinery.

- Favorable trade agreements: FTAs with the U.S., EU, and Asia-Pacific countries reduce tariffs and simplify logistics.

- Export-ready suppliers: Many manufacturers already serve international contractors, proving their reliability.

For international buyers, these advantages translate into reduced project costs, faster lead times, and guaranteed compliance with global standards.

Vietnam Outsourcing: Your Trusted Partner

At Vietnam Outsourcing (VNO), we specialize in connecting global buyers with trusted Vietnam Guard Rail suppliers. Our services include:

- A vetted network of manufacturers with proven expertise in Vietnam guard rail manufacturing.

- On-the-ground technical support to oversee production and ensure compliance.

- Independent quality inspections conducted locally before shipment.

- Experience managing projects for U.S., EU, and Asia-Pacific markets.

- Flexible solutions tailored to both government tenders and private infrastructure projects.

By partnering with VNO, buyers can minimize risks while securing high-quality guard rails at competitive costs.

Conclusion

As infrastructure projects expand worldwide, guard rail outsourcing offers businesses the opportunity to reduce costs while meeting strict safety standards. With advanced technology, strong quality control, and competitive pricing, Vietnam Guard Rail suppliers are well-positioned to serve global markets.

By working with Vietnam Outsourcing (VNO), companies gain a reliable partner that ensures compliance, consistency, and long-term value.

Ready to outsource your next guard rail project? Contact Vietnam Outsourcing (VNO) today to connect with certified suppliers in Vietnam.