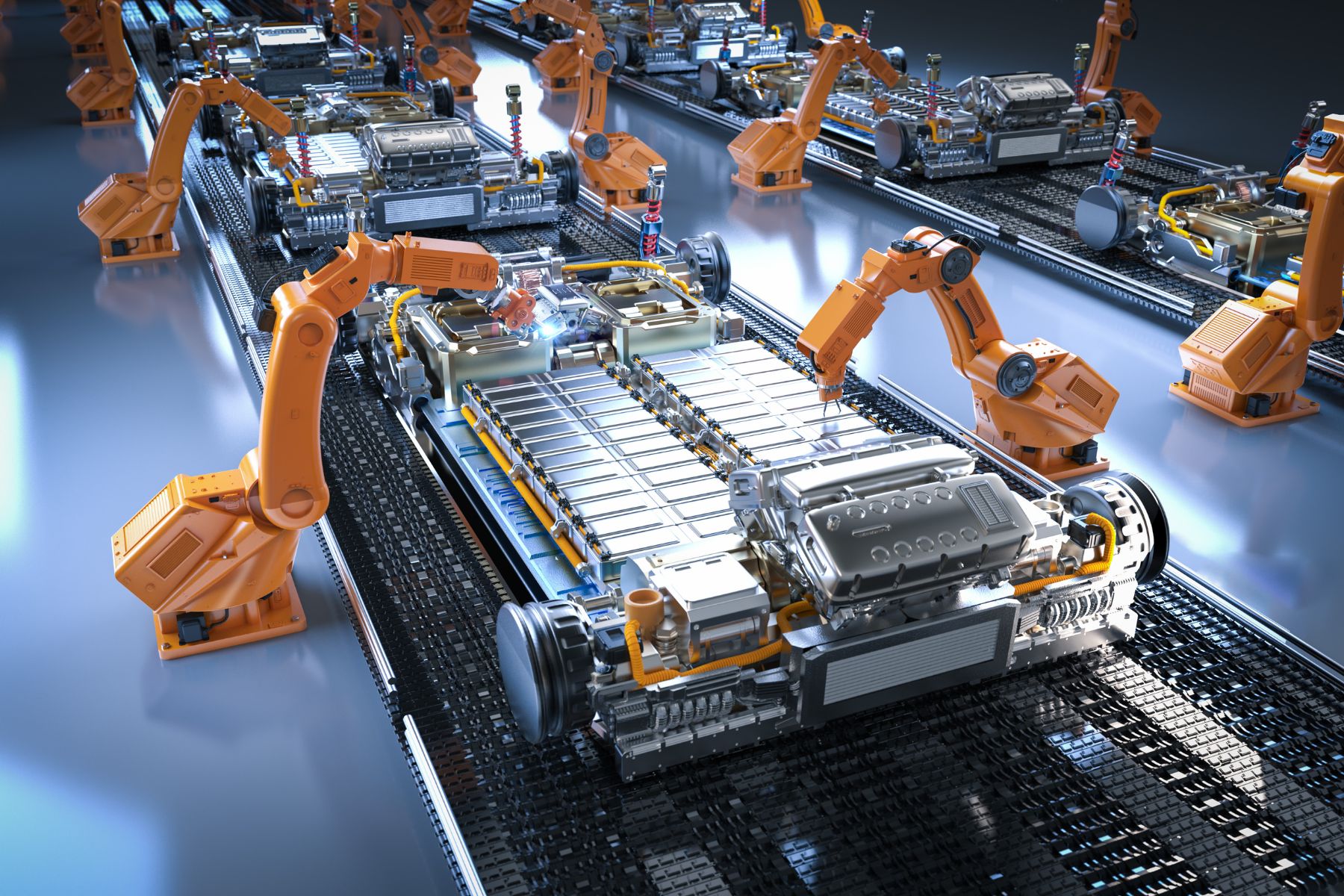

In today’s competitive business landscape, companies are constantly seeking cost-effective solutions to streamline operations and maximize efficiency. One such solution gaining traction is outsourcing, particularly in the realm of battery housing production. This article delves into the benefits of affordable battery housing outsourcing to Vietnam, providing insights into cost evaluation, advantages, cost management strategies, and market trends.

- Cost Evaluation and Benefits:

Cost evaluation plays a crucial role in the decision-making process when it comes to outsourcing battery housing production. Analyzing the benefits of outsourcing to Vietnam and comparing costs with domestic production are essential steps in determining the most cost-effective solution for businesses. Let’s delve into each aspect in detail:

Analyzing the Benefits of Outsourcing Battery Housing to Vietnam:

Outsourcing battery housing production to Vietnam offers several compelling benefits compared to other alternatives. Some of the key advantages include:

Lower Labor Costs: Vietnam boasts a competitive advantage in terms of labor costs compared to many other countries. The wage rates in Vietnam are generally lower than in developed countries, allowing businesses to achieve significant cost savings in labor-intensive manufacturing processes like battery housing production.

Favorable Government Policies: The Vietnamese government has implemented policies to attract foreign investment and promote manufacturing activities. These policies include tax incentives, favorable regulatory frameworks, and infrastructure development initiatives, creating an enabling environment for businesses engaged in outsourcing.

Skilled Workforce: Vietnam has a young and dynamic workforce with a growing pool of skilled workers, particularly in the manufacturing sector. Many Vietnamese workers possess technical expertise and proficiency in modern manufacturing technologies, making them well-suited for battery housing production.

Robust Manufacturing Infrastructure: Over the years, Vietnam has invested heavily in developing its manufacturing infrastructure, including industrial parks, logistics networks, and utilities. This infrastructure supports efficient production processes and facilitates smooth operations for businesses engaged in outsourcing activities.

Strategic Location: Vietnam’s strategic location in Southeast Asia provides access to regional markets and global supply chains. Proximity to key markets allows for shorter lead times and reduced transportation costs, enhancing the overall competitiveness of outsourcing operations.

Comparing the Costs of Domestic Production and Outsourcing to Vietnam:

When comparing the costs of domestic production with outsourcing to Vietnam, businesses must consider various factors, including labor costs, overhead expenses, material costs, and regulatory compliance. While domestic production may offer certain advantages such as proximity to the market and greater control over operations, it often comes with higher labor costs and overhead expenses. On the other hand, outsourcing to Vietnam can result in significant cost savings, particularly in labor-intensive manufacturing processes.

To accurately compare costs, businesses need to conduct a comprehensive cost analysis that takes into account all relevant factors. This analysis should include direct costs such as labor, materials, and utilities, as well as indirect costs such as overhead expenses, taxes, and regulatory compliance. Additionally, businesses should consider qualitative factors such as quality, reliability, and scalability when evaluating the overall cost-effectiveness of outsourcing to Vietnam.

Calculating the Expected Cost Benefits from Choosing Cost-Effective Outsourcing:

Choosing cost-effective outsourcing to Vietnam can yield substantial cost benefits for businesses. To calculate the expected cost benefits, businesses can use various financial metrics and models such as return on investment (ROI), net present value (NPV), and total cost of ownership (TCO). These metrics help quantify the potential cost savings and return on investment associated with outsourcing activities.

In addition to financial metrics, businesses should also consider qualitative factors such as risk mitigation, flexibility, and strategic alignment when assessing the expected cost benefits of outsourcing to Vietnam. By taking a holistic approach to cost evaluation, businesses can make informed decisions that optimize costs without compromising quality and drive long-term value creation.

Advantages of Cost-Effective Outsourcing:

Cost-effective outsourcing offers numerous advantages for businesses looking to optimize their operations while maintaining high-quality standards. Let’s explore these advantages in detail:

- Enhancing Cost Efficiency Without Compromising Quality:

One of the primary advantages of cost-effective outsourcing is its ability to enhance cost efficiency without sacrificing quality. By leveraging the lower labor costs and operational expenses available in countries like Vietnam, businesses can achieve significant cost savings compared to in-house production or outsourcing to higher-cost regions. Despite the lower costs, reputable outsourcing partners in Vietnam can deliver high-quality products and services thanks to their skilled workforce, modern infrastructure, and adherence to international quality standards. This allows businesses to reduce production costs while ensuring that the final product meets or exceeds customer expectations in terms of quality and performance.

- Comparing the Costs and Benefits Between In-House Production and Outsourcing:

Comparing the costs and benefits between in-house production and outsourcing is essential for making informed business decisions. While in-house production offers certain advantages such as greater control over the production process and intellectual property protection, it often comes with higher overhead expenses, capital investments, and operational risks. On the other hand, outsourcing to cost-effective destinations like Vietnam can result in significant cost savings, particularly in labor-intensive manufacturing processes. Businesses can benefit from lower labor costs, reduced overhead expenses, and access to specialized expertise without the need for substantial investments in infrastructure and workforce training. By carefully weighing the costs and benefits of each option, businesses can determine the most cost-effective and strategically sound approach to meet their production needs.

- Evaluating How Cost-Effective Outsourcing Can Create a Competitive Advantage for Businesses:

Cost-effective outsourcing can serve as a powerful tool for creating a competitive advantage in the marketplace. By reducing production costs and improving operational efficiency, businesses can lower their prices, increase profit margins, and gain a competitive edge over rivals. Moreover, outsourcing allows businesses to focus their resources on core competencies such as research and development, marketing, and customer service, thereby enhancing overall competitiveness and market positioning. Additionally, cost-effective outsourcing enables businesses to respond more effectively to market fluctuations, changing customer demands, and industry trends. By leveraging the benefits of cost-effective outsourcing, businesses can adapt quickly to evolving market conditions, capitalize on new opportunities, and drive sustainable growth and profitability in the long term.

In summary, cost-effective outsourcing offers a range of advantages for businesses, including enhanced cost efficiency, improved quality, and competitive advantage. By leveraging the lower costs and operational advantages available in countries like Vietnam, businesses can optimize their operations, reduce production costs, and position themselves for long-term success in the global marketplace.

Cost Management Strategy:

Cost management is a critical aspect of outsourcing operations to Vietnam, ensuring that businesses maximize efficiency and profitability while maintaining quality standards. Let’s delve into the details of cost management strategy when outsourcing to Vietnam:

- Analyzing How Businesses Can Manage and Control Costs When Outsourcing to Vietnam:

- Vendor Selection: Careful selection of outsourcing partners is crucial for effective cost management. Businesses should assess potential vendors based on factors such as expertise, reputation, capacity, and cost-effectiveness. Conducting thorough due diligence and establishing clear communication channels with vendors helps ensure alignment with cost and quality objectives.

- Contract Negotiation: Negotiating favorable terms and pricing structures with outsourcing partners is essential for cost management. Businesses should seek to establish transparent contracts that outline pricing, deliverables, performance metrics, and dispute-resolution mechanisms. Clear communication of expectations and requirements helps prevent misunderstandings and minimizes cost overruns.

- Continuous Monitoring: Regular monitoring and evaluation of outsourcing activities are essential for cost control. Businesses should establish performance metrics and key performance indicators (KPIs) to track vendor performance, quality, and adherence to budgetary constraints. Prompt identification of issues allows for timely corrective action to mitigate risks and minimize cost impacts.

- Proposing Cost-Saving Strategies Through Optimizing Production and Operations Processes:

- Process Optimization: Streamlining production and operations processes is key to achieving cost savings when outsourcing to Vietnam. Businesses should identify inefficiencies, bottlenecks, and areas for improvement in the manufacturing process. Implementing lean principles, automation, and technology integration helps increase efficiency, reduce waste, and lower production costs.

- Supply Chain Management: Effective supply chain management plays a vital role in cost optimization. Businesses should collaborate closely with vendors to ensure timely delivery of materials and components at competitive prices. Adopting just-in-time (JIT) inventory management practices and optimizing logistics and transportation routes help minimize inventory carrying costs and transportation expenses.

- Resource Allocation: Efficient resource allocation is essential for cost management. Businesses should allocate resources strategically based on demand forecasts, production schedules, and market trends. Flexible resource utilization, workforce optimization, and cross-training initiatives enable businesses to adapt to changing production requirements and minimize unnecessary costs.

- Assessing the Advantages and Disadvantages of Cost Management in the Outsourcing Process:

- Advantages:

- Cost Savings: Effective cost management helps businesses reduce production costs and improve profitability.

- Enhanced Efficiency: Streamlining processes and optimizing resources lead to increased operational efficiency and productivity.

- Competitive Advantage: Lower production costs enable businesses to offer competitive pricing, gain market share, and maintain profitability in competitive markets.

- Risk Mitigation: Proactive cost management helps identify and mitigate risks, minimizing the impact of cost overruns and unforeseen expenses.

- Disadvantages:

- Quality Risks: Overemphasis on cost reduction may compromise product quality and customer satisfaction if not managed effectively.

- Vendor Relationships: Strict cost management measures may strain relationships with outsourcing partners if not balanced with fair and transparent practices.

- Short-Term Focus: Cost management initiatives focused solely on immediate cost reduction may overlook long-term investments and strategic opportunities for growth and innovation.

In conclusion, an effective cost management strategy is essential for successful outsourcing operations to Vietnam. By analyzing costs, implementing cost-saving strategies, and assessing the advantages and disadvantages of cost management, businesses can optimize outsourcing operations, achieve cost efficiencies, and drive sustainable growth and profitability in the competitive global marketplace.

- Trend and Market Updates:

Keeping abreast of the latest trends and market updates in the battery housing outsourcing industry in Vietnam is crucial for businesses to maintain competitiveness and make informed decisions. Let’s delve into the details of this aspect:

Keeping Up with the Latest Trends:

Technology Adoption: The battery housing outsourcing industry in Vietnam is witnessing a trend towards technology adoption and innovation. Businesses are increasingly investing in advanced manufacturing technologies, automation, and digitalization to enhance production efficiency, quality, and scalability.

Sustainability Initiatives: There is a growing emphasis on sustainability and environmental responsibility in the battery housing outsourcing sector. Companies are exploring eco-friendly materials, energy-efficient processes, and waste reduction strategies to minimize their environmental footprint and meet regulatory requirements.

Customization and Personalization: Customers are demanding more customized and personalized battery housing solutions to meet their specific requirements. As a result, outsourcing partners in Vietnam are offering flexible manufacturing capabilities and customization options to cater to diverse customer needs and preferences.

Evaluating the Impact of Market Trends and Economic Factors:

Pricing Dynamics: Market trends and economic factors such as raw material prices, currency fluctuations, and labor costs can have a significant impact on pricing and outsourcing costs in Vietnam. Fluctuations in global commodity markets and changes in government policies can also influence pricing dynamics and supply chain stability.

Competitive Landscape: The competitive landscape in the battery housing outsourcing industry is evolving rapidly, with new entrants, mergers, and acquisitions reshaping the market dynamics. Businesses need to closely monitor competitor activities, market positioning, and pricing strategies to stay ahead of the curve and identify new growth opportunities.

Regulatory Environment: Changes in regulatory requirements, trade policies, and environmental regulations can affect production costs and market access in Vietnam. Businesses must stay informed about regulatory developments and compliance requirements to mitigate risks and ensure business continuity.

Proposing Market Data-Based Strategies:

Data Analytics and Market Intelligence: Utilizing data analytics and market intelligence tools can help businesses gather actionable insights into market trends, customer preferences, and competitor strategies. By analyzing market data and consumer behavior patterns, businesses can identify emerging trends, anticipate market demand, and develop targeted marketing and pricing strategies.

Strategic Partnerships: Establishing strategic partnerships with reliable suppliers, logistics providers, and technology partners can help businesses optimize their supply chain, reduce costs, and enhance operational efficiency. Collaborating with local industry associations and government agencies can also provide valuable market insights and regulatory support.

Continuous Improvement: Adopting a culture of continuous improvement and innovation is essential for staying competitive in the dynamic battery housing outsourcing market. Businesses should regularly review and optimize their production processes, technology investments, and supply chain management practices to drive efficiency gains and cost savings over time.

In conclusion, staying informed about the latest trends, market dynamics, and economic factors is essential for businesses operating in the battery housing outsourcing industry in Vietnam. By evaluating market trends, assessing their impact on pricing and outsourcing costs, and proposing data-driven strategies, businesses can ensure sustained competitiveness and profitability in the rapidly evolving marketplace.