Casting Material in Vietnam: An Introduction

Introduction Casting material in Vietnam is a foundation of modern manufacturing. Casting allows molten metal to be poured into molds and shaped into precise components. Unlike 3D printing, which dominates prototyping, casting remains the most economical and reliable solution for large-scale production. The process not only supports a wide variety

Read moreMetal casting industry in Vietnam

IntroductionThe metal casting industry plays a central role in modern manufacturing. At its core, casting is the process of pouring liquid material into a mold, allowing it to solidify, and producing a part shaped like the mold cavity. Although casting can use ceramics, plastics, or concrete, metallic materials dominate the

Read moreAn Introduction to Aluminum Alloy Material

Table of Contents Aluminum alloy combines aluminum with elements such as silicon, iron, copper, and magnesium. Because of its ductility and convenient melting point, it adapts well to industrial production. It also resists corrosion, offers high strength, and polishes easily. Unlike many other metals, aluminum alloy keeps its appearance over

Read moreEverything You Need to Know About Aluminum Industry (2025 Guide)

Everything you need to know about Aluminum Industry Table of Contents The aluminum industry has become one of the most essential sectors in global manufacturing. Lightweight, corrosion-resistant, and highly versatile, aluminum is used in industries ranging from automotive and aerospace to packaging, construction, and renewable energy. With growing demand for

Read moreSituation of CNC machining in Vietnam

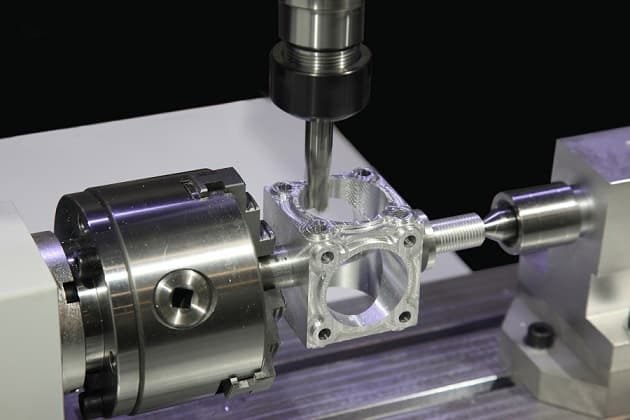

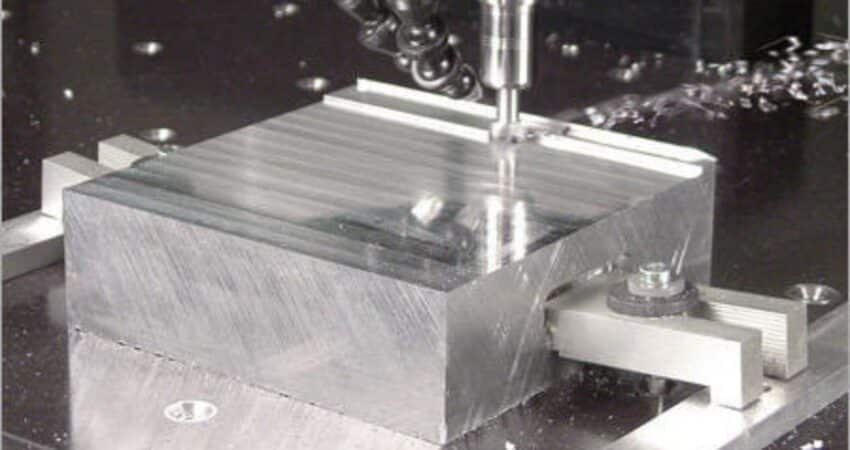

Situation of CNC machining in Vietnam Introduction Despite the high cost of equipment, demand for CNC machining in Vietnam is growing rapidly. Companies are investing in advanced machines, both imported and locally assembled, to serve domestic and international buyers. Today, Vietnam CNC machining services are used across woodworking, automotive, aerospace,

Read moreThe most essentials for CNC machines quality control

Introduction How can you guarantee CNC machines quality control when your service provider is located on the other side of the world? This is a common challenge for businesses outsourcing prototypes, small-batch components, or large production runs. If you are working with a third-party partner for CNC machining in Vietnam,

Read moreProminent Die Casting Material Options in Modern Manufacturing

Introduction Die casting is one of the most efficient ways to manufacture precision components at scale. The process forces molten metal into a mold cavity under high pressure. Because the method requires only four key steps, it reduces incremental costs and makes large-volume production affordable. As a result, die casting

Read moreHow to cut down costs on your CNC projects

How to cut down costs on your CNC projects Introduction CNC milling and machining are powerful manufacturing methods, but they are rarely cheap. Without careful planning, CNC costs can rise quickly, putting pressure on budgets and reducing profit margins. However, by identifying the key factors that influence costs, manufacturers and

Read moreCNC Machining Trends 2025: 6 Innovations You Must Know

Introduction The pace of change in CNC machining is faster than ever. Because of new technologies such as AI-driven automation and cloud-based digital twins, manufacturers are rethinking how they design, produce, and deliver parts. As a result, companies that adopt these innovations gain clear advantages in efficiency, quality, and sustainability.

Read more