Vietnam CNC Router Cutting: Precision and Cost-Effective Solutions

Introduction In recent years, Vietnam CNC router cutting has become a popular choice across multiple industries. Unlike Vietnam CNC Milling Service use heavy machine for hard metals, CNC routers focus on wood, plastics, composites, and soft metals such as aluminum. They give businesses a cost-friendly yet accurate solution that combines

Read moreVietnam Metal Lathe Tooling: Precision and Outsourcing Advantages

Introduction Vietnam Metal lathe tooling is becoming an essential part of global supply chains. A CNC lathe is a computer-controlled machine used to rotate a workpiece while cutting, drilling, or shaping it with precision tools. Since entering the industrial market, CNC lathes have transformed traditional manufacturing by introducing speed, automation,

Read moreCNC Machining Process: Step-by-Step Guide

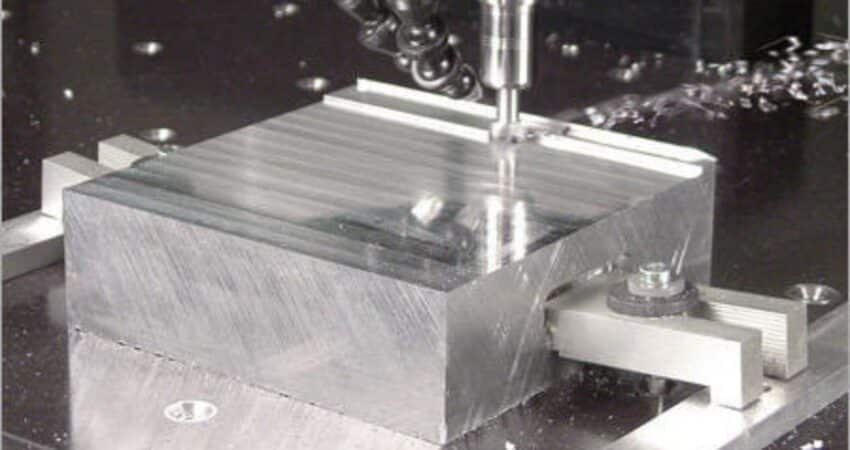

Introduction The CNC machining process is a cornerstone of modern manufacturing, allowing businesses to produce highly precise and repeatable components. By combining computer programming with automated machinery, this precision machining method ensures efficiency, accuracy, and scalability. To better understand how this works, let’s break the CNC machining process down into

Read moreSituation of CNC machining in Vietnam

Situation of CNC machining in Vietnam Introduction Despite the high cost of equipment, demand for CNC machining in Vietnam is growing rapidly. Companies are investing in advanced machines, both imported and locally assembled, to serve domestic and international buyers. Today, Vietnam CNC machining services are used across woodworking, automotive, aerospace,

Read moreThe most essentials for CNC machines quality control

Introduction How can you guarantee CNC machines quality control when your service provider is located on the other side of the world? This is a common challenge for businesses outsourcing prototypes, small-batch components, or large production runs. If you are working with a third-party partner for CNC machining in Vietnam,

Read moreHow to cut down costs on your CNC projects

How to cut down costs on your CNC projects Introduction CNC milling and machining are powerful manufacturing methods, but they are rarely cheap. Without careful planning, CNC costs can rise quickly, putting pressure on budgets and reducing profit margins. However, by identifying the key factors that influence costs, manufacturers and

Read moreCNC Machining Trends 2025: 6 Innovations You Must Know

Introduction The pace of change in CNC machining is faster than ever. Because of new technologies such as AI-driven automation and cloud-based digital twins, manufacturers are rethinking how they design, produce, and deliver parts. As a result, companies that adopt these innovations gain clear advantages in efficiency, quality, and sustainability.

Read more