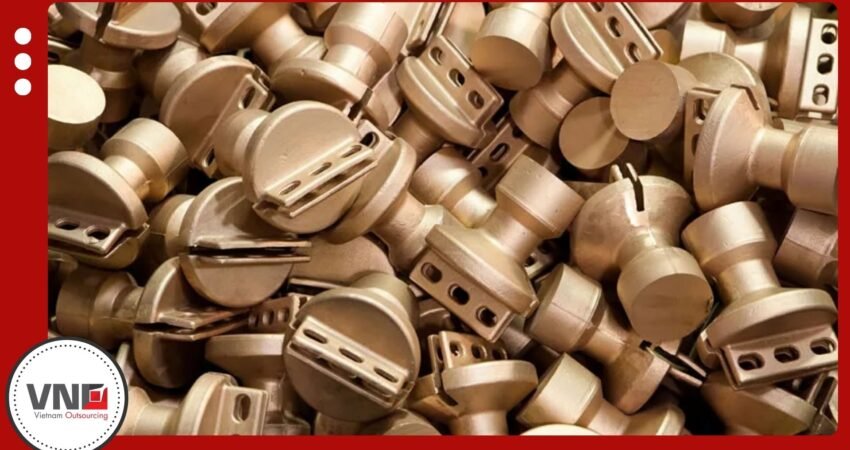

Copper Casting

What is Copper Casting? Copper casting is a process that shapes copper into strong, durable products by melting the die cast metal and pouring it into a mold cavity. Once the molten copper cools and solidifies, it takes on the form of the mold with reliable accuracy. This method has

Read moreSteel Casting: Methods, Processes, and Applications

Introduction Steel casting plays a critical role in modern industry, providing durable and versatile materials for construction, automotive, and heavy machinery. By pouring molten steel into molds and cooling it into solid form, manufacturers create both large blocks for forging and long bars for rolling. The development of continuous casting

Read moreAluminum Casting in Vietnam

Introduction Aluminum casting in Vietnam is expanding rapidly as industries and consumers seek lightweight, durable, and corrosion-resistant solutions. Aluminum alloys combine strength with low weight, making them more effective than ordinary steel (although, you may also curious of how we do Steel Casting in Vietnam) in many cases. In everyday

Read moreCasting Material in Vietnam: An Introduction

Introduction Casting material in Vietnam is a foundation of modern manufacturing. Casting allows molten metal to be poured into molds and shaped into precise components. Unlike 3D printing, which dominates prototyping, casting remains the most economical and reliable solution for large-scale production. The process not only supports a wide variety

Read moreMetal casting industry in Vietnam

IntroductionThe metal casting industry plays a central role in modern manufacturing. At its core, casting is the process of pouring liquid material into a mold, allowing it to solidify, and producing a part shaped like the mold cavity. Although casting can use ceramics, plastics, or concrete, metallic materials dominate the

Read moreProminent Die Casting Material Options in Modern Manufacturing

Introduction Die casting is one of the most efficient ways to manufacture precision components at scale. The process forces molten metal into a mold cavity under high pressure. Because the method requires only four key steps, it reduces incremental costs and makes large-volume production affordable. As a result, die casting

Read moreThe benefit of die casting in Vietnam

Introduction The benefit of die casting in Vietnam is becoming clearer as the country rises as a global manufacturing hub. With decades of investment in infrastructure, skilled labor, and international trade agreements, Vietnam die casting supplier now provides cost-effective and reliable die casting solutions. This progress offers foreign buyers an

Read more