Situation of CNC machining in Vietnam

Introduction

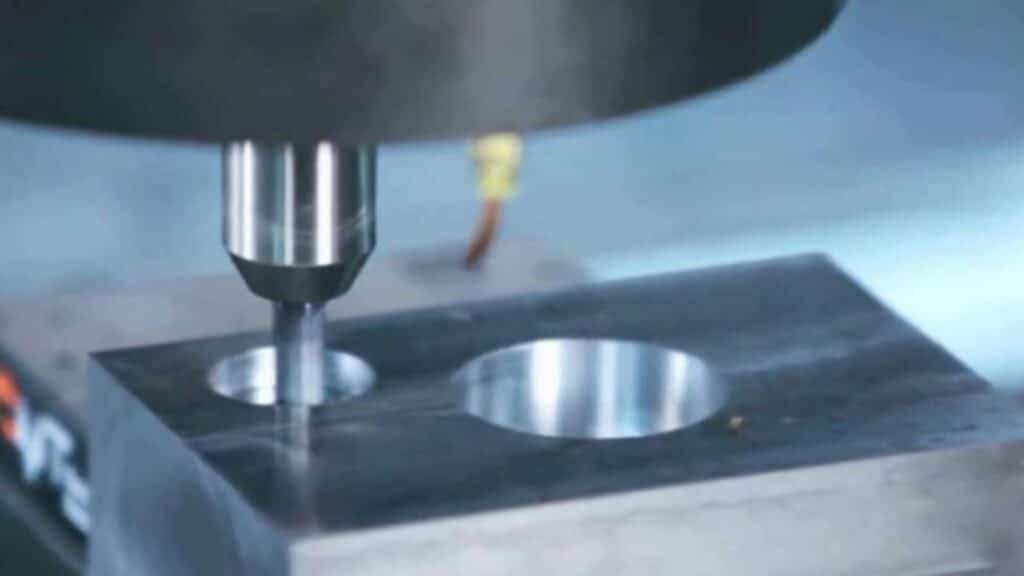

Despite the high cost of equipment, demand for CNC machining in Vietnam is growing rapidly. Companies are investing in advanced machines, both imported and locally assembled, to serve domestic and international buyers. Today, Vietnam CNC machining services are used across woodworking, automotive, aerospace, and heavy industry, helping position Vietnam as a reliable global partner.

Current Situation of the Machining Industry in Vietnam

Most CNC machines in Vietnam are imported, with two main groups:

-

Taiwanese and Chinese machines – affordable and widely used by small and mid-sized factories.

-

Japanese and German machines – advanced, high-precision models for suppliers serving global clients.

In addition, two domestic trends exist:

-

Many workshops buy second-hand machines to lower investment costs.

-

Some companies manufacture structural components and assemble machines locally, gradually reducing import dependence.

This mix provides flexibility and allows Vietnam’s machining sector to serve a broad range of projects, from prototypes to mass production.

Applications of Vietnam CNC Machining Services

CNC technology has transformed how industries operate in Vietnam.

-

Furniture and woodworking: CNC routers and milling machines allow rapid engraving, cutting, and pattern design.

-

Automotive and electronics: With rising demand for precision molds and complex parts, Vietnam 5 axis machining plays a key role in producing high-value components.

-

Steel structures and heavy industry: CNC cutting systems are used to shape metal with precision. Oxygen, plasma, and laser cutting technologies allow factories to deliver both simple and complex structures efficiently.

Conclusion

The machining industry in Vietnam continues to expand, fueled by demand from domestic growth and international outsourcing. By adopting modern machines and advanced methods such as 5 axis machining, suppliers are improving efficiency, precision, and cost-effectiveness.

For global buyers, Vietnam CNC machining services offer an excellent balance of CNC machines quality control, flexibility, and competitive pricing.

Looking to source precision machining parts in Vietnam? Contact Vietnam Outsourcing (VNO) today to connect with trusted partners offering reliable Vietnam CNC machining services tailored to your business needs.