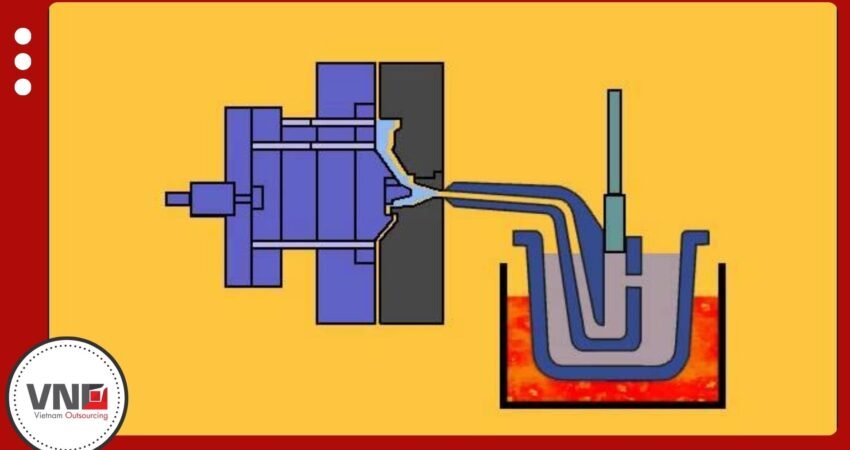

Hot Chamber Casting Machine: Working Principle and Process

Introduction The hot chamber die casting machine is one of the most widely used systems in modern manufacturing. It is fast, efficient, and well-suited for metals with low melting points such as zinc, lead, and magnesium. Unlike cold chamber casting, the plunger of a hot chamber system sits directly in

Read moreCold Chamber Casting Machine: Types and Working Principles

Introduction A cold chamber die casting machine is widely used for casting metals with high melting points such as aluminum, magnesium, and zinc alloys. Unlike hot chamber casting, where the injection system is submerged in molten metal, the cold chamber method introduces liquid metal into a separate chamber before high

Read moreCasting machinery in Vietnam

What Is Casting Machinery? Casting machinery refers to specialized machines that shape molten metal into solid parts. These machines create molds, pour molten metal, and allow it to cool and solidify. Once hardened, the metal takes on the precise form of the mold. Casting machinery is vital across industries such

Read moreMagnesium Casting: Processes, Alloys, and Applications

Introduction Magnesium casting is a modern and eco-friendly technology that produces millions of lightweight, recyclable components. It plays a vital role in industries such as electronics, automotive, aerospace, and sporting goods. By combining traditional casting methods with advanced techniques, Vietnam die casting supplier can create strong, thin-walled, and cost-efficient magnesium

Read moreZinc casting in Vietnam

Introduction to Zinc Casting Zinc casting is one of the most widely applied processes in manufacturing today. Unlike aluminum, zinc alloys melt at lower temperatures and require less pressure during production. This characteristic extends mold life and reduces costs, making zinc a practical choice of Vietnam die casting supplier for

Read moreTitanium Casting: Properties, Methods, and Applications

Introduction Titanium casting is one of the most advanced processes in metalworking. The metal’s strength, light weight, and resistance to corrosion make it essential for aerospace, marine, energy, and medical applications. However, titanium reacts easily at high temperatures, so Vietnam die casting supplier must control the process carefully to ensure

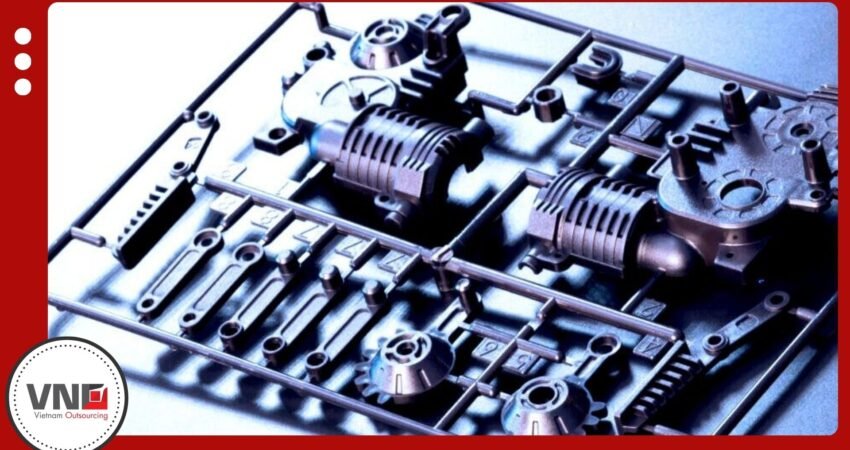

Read moreDie Cast Metal: Process, Methods, and Applications

Introduction Die cast metal is one of the most widely used manufacturing processes today. It allows the creation of complex shapes with high precision and excellent surface quality. Many everyday items—from toy cars to real automotive parts—are produced using die casting. Because the process often eliminates the need for extra

Read moreCopper Casting

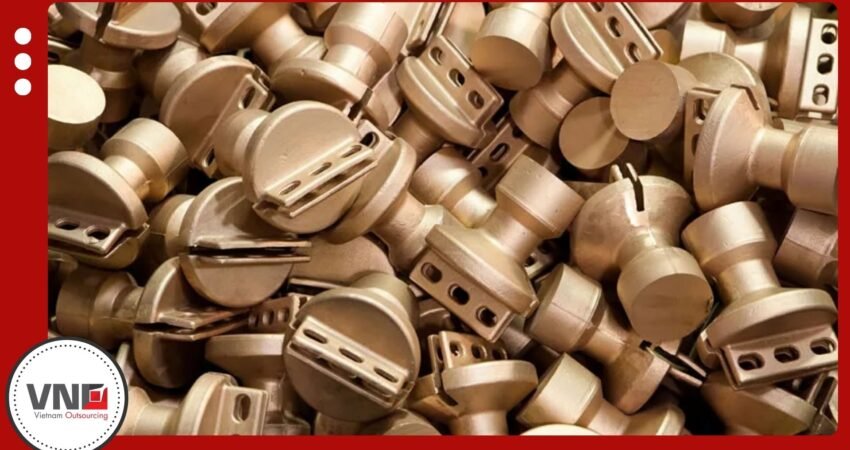

What is Copper Casting? Copper casting is a process that shapes copper into strong, durable products by melting the die cast metal and pouring it into a mold cavity. Once the molten copper cools and solidifies, it takes on the form of the mold with reliable accuracy. This method has

Read moreSteel Casting: Methods, Processes, and Applications

Introduction Steel casting plays a critical role in modern industry, providing durable and versatile materials for construction, automotive, and heavy machinery. By pouring molten steel into molds and cooling it into solid form, manufacturers create both large blocks for forging and long bars for rolling. The development of continuous casting

Read moreAluminum Casting in Vietnam

Introduction Aluminum casting in Vietnam is expanding rapidly as industries and consumers seek lightweight, durable, and corrosion-resistant solutions. Aluminum alloys combine strength with low weight, making them more effective than ordinary steel (although, you may also curious of how we do Steel Casting in Vietnam) in many cases. In everyday

Read more