CNC Machining Process: Step-by-Step Guide

Introduction The CNC machining process is a cornerstone of modern manufacturing, allowing businesses to produce highly precise and repeatable components. By combining computer programming with automated machinery, this precision machining method ensures efficiency, accuracy, and scalability. To better understand how this works, let’s break the CNC machining process down into

Read moreCentrifugal casting in Vietnam

Introduction Centrifugal casting is a process where molten metal is poured into a rotating mold. As the mold spins, centrifugal force pushes the liquid metal outward. The alloy spreads evenly along the inner surface of the mold, solidifying into a dense and uniform casting. This method is especially effective for

Read moreLow Pressure Casting: Process, Advantages, and Applications

Introduction Low pressure casting is a metal casting method where molten metal is pressed into a mold using pressure ranging from 8 up to several hundred ata. This controlled pressure allows the alloy to fill the mold completely, producing parts with excellent mechanical strength, precision, and surface quality. Advantages of

Read moreInvestment Casting: Process, Characteristics, Advantages, and Applications

Introduction Investment casting is a precision metal casting method widely used by Vietnam die casting suppliers. Instead of adhesives, this technique uses polystyrol (expanded polystyrene) patterns and sand molds stabilized by vacuum aspiration. When molten metal is poured, it vaporizes the polystyrol pattern and gradually fills the cavity, forming the

Read moreSand Casting vs Die Casting: Key Differences Explained

Introduction When comparing sand casting vs die casting, both are essential methods in modern manufacturing. They each provide unique advantages and challenges, making them suitable for different applications. Knowing how they differ in process, cost, and performance helps businesses choose the right solution. You might also want to know about

Read moreGravity Casting in Vietnam: Process, Characteristics, and Applications

Introduction Gravity casting in Vietnam has become a reliable solution for producing non-ferrous metal parts. Foundries use this method to cast aluminum, zinc, and copper components with excellent surface quality. Vietnam die casting supplier often chooses gravity casting for large-sized details where cost efficiency and durability are essential. Characteristics of

Read moreCasting methods in Vietnam

Introduction The casting method in Vietnam reflects both the heritage of traditional craftsmanship and the progress of modern technology. From sand-clay molds used for centuries to advanced die casting and centrifugal systems, Vietnam has embraced multiple casting techniques to serve industries such as automotive, energy, shipbuilding, and aerospace. Casting remains

Read moreSand Casting Products in Vietnam: Characteristics and Applications

Introduction Sand casting products in Vietnam play a vital role in the country’s growing manufacturing sector. As one of the oldest and most versatile casting methods, sand casting allows manufacturers to produce metal parts in a wide range of sizes and shapes. From components as small as 56 grams to

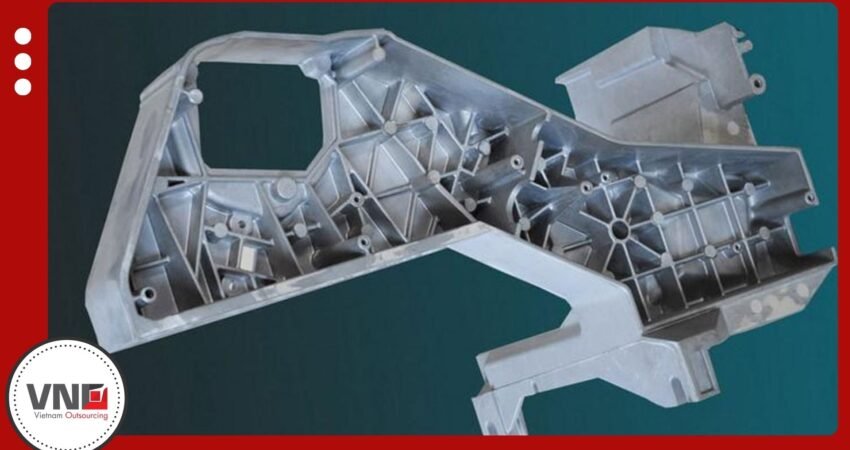

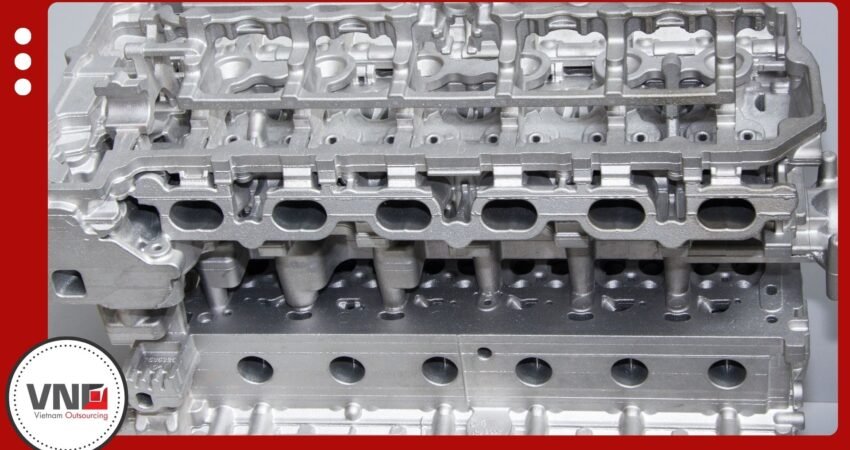

Read moreDie Casting Products: Applications and Advantages

Introduction Die casting products are part of our everyday lives, even if we rarely notice them. This process supports both commercial and industrial production, from automotive drive systems and engine parts to telecommunications equipment, marine components, and household tools. You can find die casting products in hospital pumps, cylinders, vehicle

Read moreCasting Products in Vietnam: A Complete Overview

Introduction The casting products in Vietnam sector is becoming a key part of the global supply chain. Casting turns molten metal into parts used in industries such as automotive, construction, shipbuilding, and energy. Vietnam die casting supplier now combines skilled labor, modern factories, and cost advantages. As a result, the

Read more