Strategic Outsourcing Consulting

Factory Audit Solutions

With our extensive industry knowledge and network, we excel in identifying reliable and high-quality suppliers for our clients.

30+ Customers

We are serving 30 customers worldwide

200+ Project

With 7 millions parts shipped annually

Contact Us For Consultation

Our process

Get Started with VNO’s Factory Audit Solutions

At Vietnam Outsourcing Pte Ltd (VNO), we believe that every successful partnership starts with quality assurance.

If you’re ready to begin your outsourcing journey, send your inquiry today to info@vnoutsourcing.com, or schedule a meeting via WhatsApp, Zoom, or Google Meet.

Within 24 hours, your personal supply-chain expert will contact you to understand your needs and guide you through our structured audit and development process. Through a comprehensive, step-by-step approach, we ensure that your manufacturing project in Vietnam delivers measurable results.

Send your Inquiry

Send your inquiry today to info@vnoutsourcing.com or click here to contact us

Schedule meeting

We will reach you within 24 hours Through Whassap, Zoom, Google meet

Your personal expert

Your very own personal supply chain expert that in charge of solving your inquiry

Get your request done

Through a comprehensive step-by-step process and visual result

Why us ?

Why Factory Audit Solutions Matter

As a metal procurement outsourcing company in Vietnam, VNO recognizes that quality is the foundation of long-term success.

Our factory audit solutions in Vietnam are designed to help global clients verify factory capability, control quality risks, and guarantee consistent performance before, during, and after production.

We combine international quality standards, local engineering knowledge, and hands-on supervision to ensure your products meet the highest expectations.

Our Five-Step Factory Audit Solutions Process

Step 1: Establishing Comprehensive Quality Standards

We begin every audit by defining clear and measurable quality standards.

These standards are based on your specifications, international norms, and industry best practices. They cover:

Product quality and production processes

Compliance with ISO and regulatory requirements

Customer-specific technical and packaging criteria

By setting precise benchmarks, we ensure transparency, accountability, and consistency throughout every factory audit.

Step 2: Experienced Quality Assurance Team

Our quality assurance team consists of professionals with deep experience in metal manufacturing and international auditing.

They are trained in ISO 9001, IATF 16949, and other global frameworks.

During factory audits, our experts assess manufacturing processes, evaluate quality systems, and confirm implementation of your defined standards.

Moreover, they identify potential risks early and recommend actionable improvements.

This proactive approach allows VNO to deliver factory audit solutions in Vietnam that go beyond simple inspection — we provide strategic insight for long-term reliability.

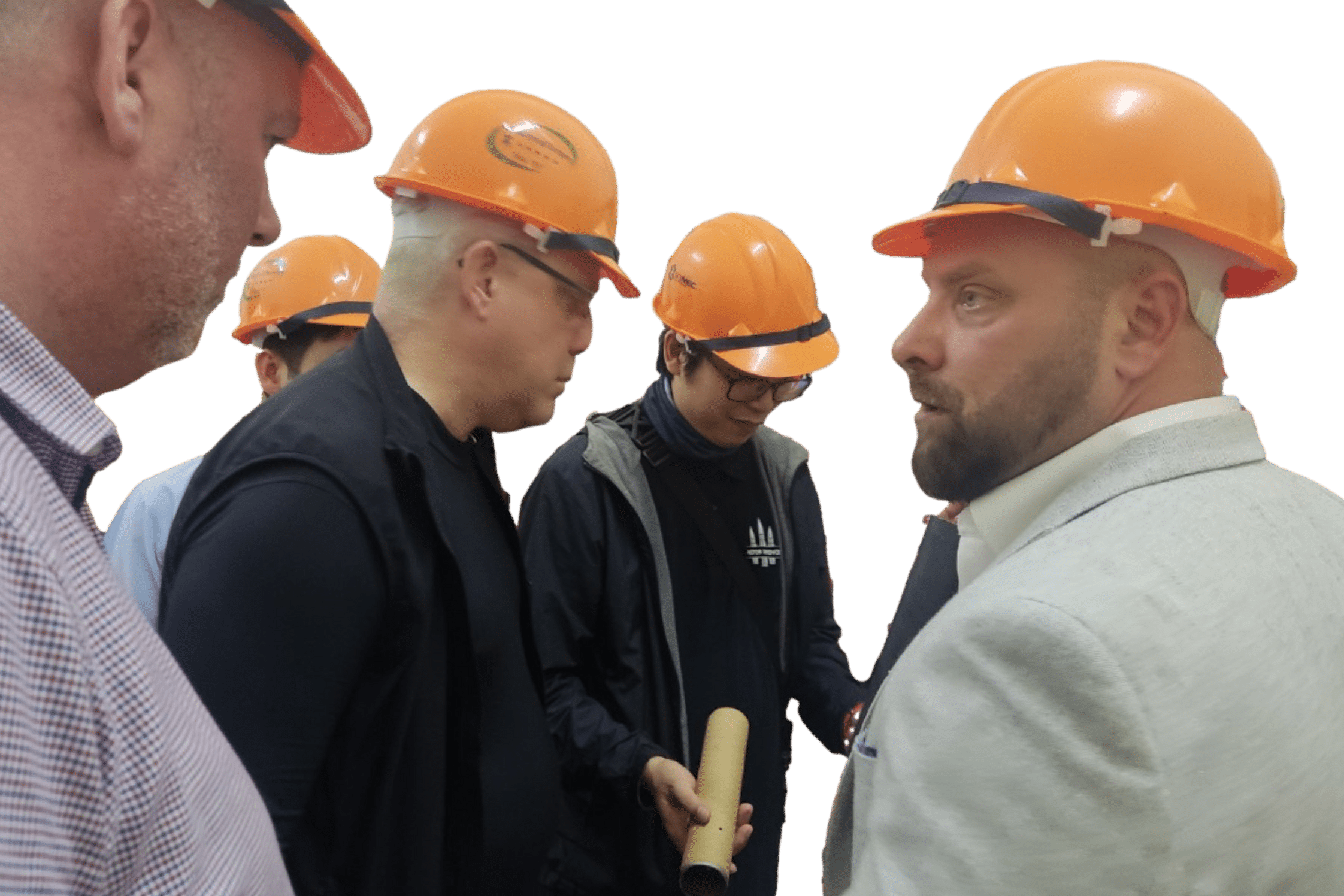

Step 3: Robust Audit Processes and On-Site Inspections

Each audit follows a systematic and transparent process.

Our team conducts on-site visits to inspect facilities, review documentation, and evaluate production lines.

We examine:

Quality management systems and testing methods

Calibration and maintenance records

Worker competence and training programs

Compliance with certifications and safety practices

Through these audits, we gain a clear picture of the factory’s real capacity to deliver consistent quality.

As a result, our clients can make confident sourcing decisions backed by verified data.

Step 4: Non-Conformance Management and Corrective Actions

If any non-conformances or deviations appear during the audit, we act immediately.

Our specialists collaborate with the factory to analyze root causes and develop corrective measures.

We guide suppliers in implementing sustainable solutions that improve control systems, traceability, and defect prevention.

By resolving issues early, VNO’s factory audit solutions in Vietnam help clients maintain steady production flow and prevent costly delays.

Step 5: Continuous Improvement and Customer Feedback

At VNO, every audit is also an opportunity to learn.

After completion, we collect customer feedback, evaluate audit outcomes, and identify areas for process enhancement.

These insights feed into our continuous improvement program, strengthening both our audit methodology and the performance of our partner factories.

Through this cycle of feedback and refinement, we consistently raise quality standards for all clients.

TEAM MEMBER

Meet our Professional

With over 25 years of global supply-chain experience, VNO’s team includes engineers, auditors, and logistics specialists who truly understand the metal manufacturing ecosystem.

We serve as both technical advisors and risk-sharing partners, ensuring that every project meets international expectations for quality and compliance.

Whether it’s sourcing metal components, managing logistics, or supervising production, our experts are dedicated to delivering end-to-end outsourcing excellence.

Looking for a reliable manufacturing partner in Asia?

Discover the power of Vietnam manufacturing services with VNO and bring your production goals to life.

Your partner comprehensive outsourcing solutions.

Through our dedicated factory audit solutions in Vietnam, VNO helps global clients:

- Mitigate manufacturing and sourcing risks

- Ensure consistent product quality

- Strengthen supplier relationships

- Maintain stable, compliant supply chains

By choosing VNO, you gain a trusted partner focused on transparency, improvement, and measurable results. Ensure your project stays on track from concept to completion with our Development Follow-Up service, designed to manage every production milestone and quality checkpoint efficiently.