Strategic Outsourcing Consulting

Development follow-up

With our extensive industry knowledge and network, we excel in identifying reliable and high-quality suppliers for our clients.

30+ Customers

We are serving 30 customers worldwide

200+ Project

With 7 millions parts shipped annually

Contact Us For Consultation

Our process

INITIATE YOUR OUTSOURCING TODAY

At Vietnam Outsourcing Pte Ltd (VNO), we understand that starting a new project overseas requires both trust and precision. When you begin your partnership with us, your Vietnam production follow up process starts immediately.

Send your Inquiry

Send your inquiry today to info@vnoutsourcing.com or click here to contact us

Schedule meeting

We will reach you within 24 hours Through Whassap, Zoom, Google meet

Your personal expert

Your very own personal supply chain expert that in charge of solving your inquiry

Get your request done

Through a comprehensive step-by-step process and visual result

Why us ?

Why Choose VNO for Vietnam Production Follow Up

As a metal procurement and outsourcing company in Vietnam, VNO provides end-to-end development and production follow up services designed to ensure that every project runs smoothly. Our philosophy is simple: clear communication, strong supervision, and continuous improvement lead to successful outsourcing.

We manage your project directly on the ground — monitoring factory operations, performing quality checks, and keeping you informed at every stage. This approach helps our clients meet their quality, timeline, and cost goals with confidence.

Our Six-Step Vietnam Production Follow Up Process

Step 1: Regular Communication for Effective Vietnam Production Follow Up

Every project begins with open, transparent communication. We establish clear lines between your team and ours to ensure all expectations are aligned. Regular project updates include progress reports, milestones achieved, and early notice of potential challenges.

By maintaining constant contact, we make sure your team always has full visibility of what’s happening inside the factory. This proactive communication style reduces misunderstandings and builds long-term trust.

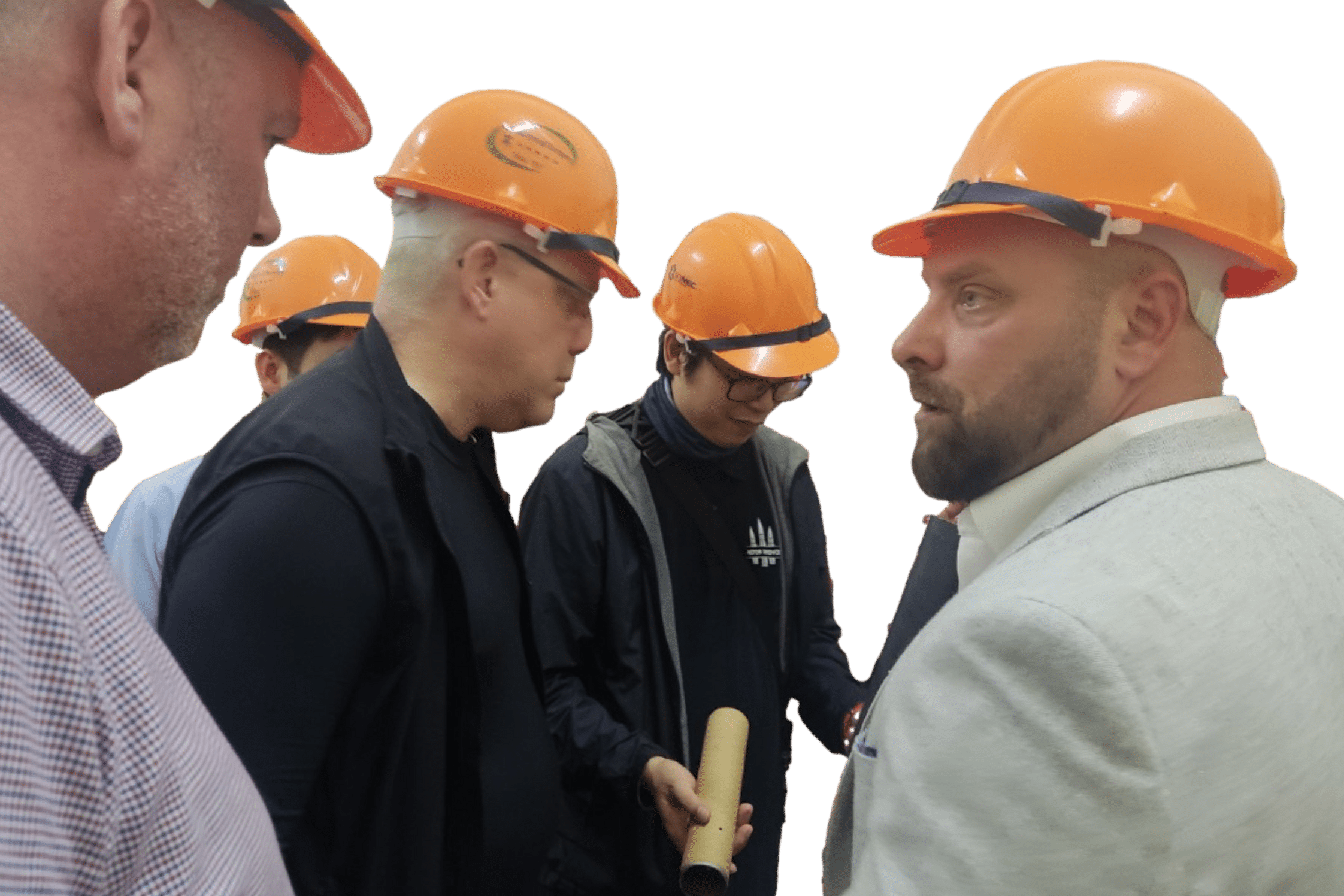

Step 2: On-Site Vietnam Production Management and Monitoring

Once development begins, our project managers work directly on-site with local manufacturing partners. They supervise every step — from prototype approval to mass production — ensuring compliance with your technical drawings, materials, and standards.

Because our engineers are located within major industrial zones such as Bac Ninh, Binh Duong, and Dong Nai, we can visit factories regularly, verify progress, and immediately address any issues that could affect schedule or quality. This level of on-site control sets VNO apart from remote brokers.

Step 3: Quality Control — The Heart of Vietnam Production Follow Up

Quality assurance is central to every VNO project. Our team conducts inspections and audits at critical stages — incoming materials, in-process production, and pre-shipment.

We check dimensions, tolerances, coatings, and surface finishes using international standards such as ISO 9001 and IATF 16949. Moreover, all results are documented and shared with you through visual reports.

By implementing strict quality control in our Vietnam production follow up, we minimize risks and guarantee consistent performance for every batch.

Step 4: Capacity Planning and Continuous Vietnam Production Monitoring

To maintain efficiency, we closely monitor each factory’s production schedule and capacity. Our planners track machine utilization, workforce allocation, and material flow, preventing bottlenecks before they appear.

When adjustments are necessary, we coordinate quickly between the supplier and your team to keep the project on schedule. As a result, you gain real-time insight into how your order is progressing — without the need to manage multiple suppliers yourself.

Step 5: Issue Resolution in Vietnam Manufacturing Projects

Even the best-planned projects can face unexpected challenges. When that happens, VNO’s engineers step in fast. We identify root causes, collaborate with the factory on corrective actions, and follow up until the issue is resolved.

This structured problem-solving method reduces downtime, protects product quality, and safeguards delivery deadlines. Our goal is simple: ensure your project stays on track through professional Vietnam production follow up and technical leadership.

Step 6: Continuous Improvement for Stronger Vietnam Production Follow Up

After each project concludes, VNO conducts a full performance review. We analyze what went well, what could improve, and how to enhance efficiency for future orders. Lessons learned are shared across our supplier network to strengthen overall standards.

This culture of continuous improvement helps our clients achieve better lead times, lower defect rates, and optimized costs with every new project.

TEAM MEMBER

Meet our Professional

VNO’s team brings together 25 years of global supply-chain experience. We are not only coordinators — we are technical and risk-sharing partners. Our engineers, auditors, and logistics specialists understand the complexities of metal manufacturing and are dedicated to ensuring your success.

Whether you’re sourcing aluminum die-cast parts, precision-machined components, or fabricated assemblies, your project is managed by experts who know both the technical details and the commercial realities of production in Vietnam. Looking for a reliable manufacturing partner in Asia?

Discover the power of Vietnam manufacturing services with VNO and bring your production goals to life.

Your partner comprehensive outsourcing solutions.

Through our comprehensive Vietnam production follow up system, VNO provides complete project visibility, strong quality control, and reliable communication. We believe that consistent follow-up is the bridge between planning and success.

By supervising progress closely, solving issues quickly, and improving continuously, we help our clients achieve results that meet — and often exceed — their expectations for quality, delivery, and cost-efficiency. You might also want to know about our Factory Audit Solutions in Vietnam