Introduction

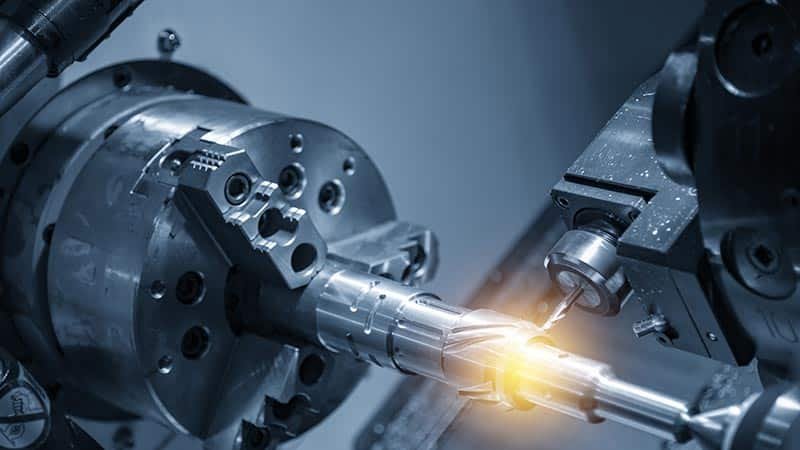

Vietnam Metal lathe tooling is becoming an essential part of global supply chains. A CNC lathe is a computer-controlled machine used to rotate a workpiece while cutting, drilling, or shaping it with precision tools. Since entering the industrial market, CNC lathes have transformed traditional manufacturing by introducing speed, automation, and repeatable accuracy.

For businesses looking to outsource machining operations, CNC lathes provide a cost-effective way to produce large volumes of consistent, high-quality components. In Vietnam, suppliers are increasingly investing in CNC technology, making the country a rising hub for lathe tooling and other precision machining services.

Advantages of CNC Lathe Machining

The benefits of CNC lathe machining explain why Vietnam Metal lathe tooling is gaining international attention.

1. Flexible Machining Capabilities

CNC lathes can quickly switch between different parts with minimal setup time. This flexibility reduces downtime and makes them ideal for both small-batch prototypes and high-volume production runs.

2. Reduced Dependence on Operator Skill

Unlike traditional lathes, CNC lathe quality is not determined by manual craftsmanship. Operators mainly handle programming, monitoring, and troubleshooting. The final product quality relies on the machine’s accuracy, reducing variation and ensuring consistency.

3. High Precision and Performance

Because CNC lathes follow pre-programmed instructions, they achieve levels of accuracy and repeatability that manual methods cannot match. This leads to improved efficiency, better product quality, and fewer reworks.

4. Lower Labor and Production Costs

By reducing the need for highly skilled manual workers, CNC lathe machining helps minimize labor expenses. Furthermore, automation boosts productivity, shortens cycle times, and reduces material waste, leading to lower overall production costs.

5. Reusable Machining Programs

Once a CNC program is created, it can be stored and reused for future production. This not only saves time but also guarantees consistent quality across multiple production batches.

6. Optimized Cutting and Tool Life

CNC lathes operate with high cutting speeds and precision, extending tool life and reducing the need for frequent replacements. They also minimize reliance on jigs and other fixtures, streamlining the process.

7. Stable and Long-Term Operation

CNC lathes are designed for continuous operation with minimal downtime. They maximize equipment utilization, ensuring businesses get the most out of their investment.

8. Faster Setup and Quality Assurance

Because finished parts meet exact specifications from the first run, less time is wasted on rework or post-processing. This saves both setup time and inspection effort, ensuring faster project delivery.

9. Strong Business Competitiveness

By lowering labor costs, reducing waste, and improving efficiency, companies using CNC lathes can offer high-quality products at competitive prices. This strengthens reputation, attracts customers, and opens opportunities in demanding markets like automotive, aerospace, and electronics.

Why Outsource Metal Lathe Tooling to Vietnam?

Outsourcing Vietnam Metal lathe tooling offers several advantages for international buyers.

- Cost Savings – Vietnam offers competitive production costs thanks to lower labor rates combined with increasing automation. This makes Vietnam an attractive alternative to China and other Asian markets.

- Young and Skilled Workforce – Vietnamese machinists are adaptable, eager to learn, and trained in international standards. This ensures both efficiency and quality for global clients.

- Modern Equipment – Many factories invest in advanced CNC lathes from Japan, Germany, and the U.S., ensuring they can meet strict international requirements.

- Improved Technology – Vietnam’s mechanical industry is moving beyond low-cost production by adopting Industry 4.0 practices, enhancing precision, streamlining CNC machining process, and reducing error rates.

- Quality Assurance – At Vietnam Outsourcing (VNO), local technicians support suppliers, while sample products undergo inspection by experts in the UK and China before shipment. This ensures products meet international standards before delivery.

Conclusion

CNC lathes are transforming the manufacturing industry, offering automation, consistency, and cost efficiency. As more companies seek reliable partners in Asia, Vietnam Metal lathe tooling stands out for its balance of quality, affordability, and strong technical expertise.

By outsourcing to Vietnam, businesses not only save on costs but also gain access to a young, skilled workforce and world-class machinery. With thorough inspections and dedicated support, Vietnam Outsourcing (VNO) ensures every client receives high-quality lathe-machined parts that meet global expectations.

Looking for a trusted partner in CNC lathe machining? Contact VNO today to access reliable Vietnam Metal lathe tooling services tailored to your production needs.