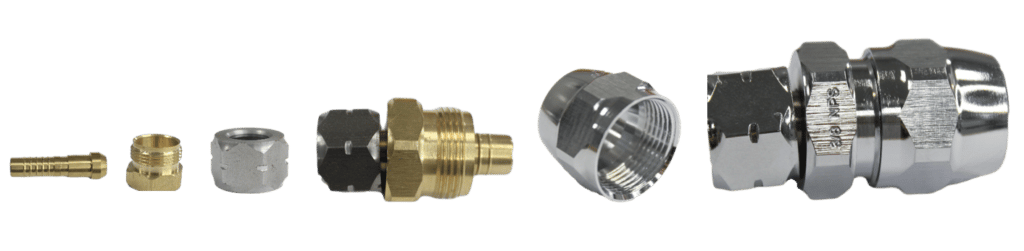

Swivel

I. Overview

This Swivel Connector Production case study shows how Vietnam Outsourcing (VNO) helped a global leader in surface treatment technology shift its manufacturing from China to Vietnam.

The customer previously produced most hardware in China but needed a new supply base. Rising costs and the U.S.–China trade war made diversification essential.

VNO partnered with a Vietnamese supplier specializing in brass valves and connectors. The factory had complete capabilities, from hot forging and CNC machining to plating and assembly. Together, they developed a Swivel Connector Production line that met strict international quality standards while remaining cost-efficient.

II. Process

This product is mature and high-volume, consisting of several precision components assembled together. Therefore, to stay competitive, the supplier must maintain in-house process capabilities and a high level of automation for efficiency and consistency.

Copper billets are forged or extruded into the initial shapes required for the connectors.

CNC machining operations shape the internal and external features, ensuring tight tolerances and smooth threading.

Each component is plated for corrosion resistance and surface protection, following strict quality standards.

All machined and plated components are assembled into the final Swivel Connector, which is tested for leak-proof performance and mechanical reliability.

“Despite brass valves and connectors are the supplier’s bread & butter. It’s still took

them 7 months and 4 submissions to pass the First Article.”

Chris Mooney – CEO of CNO and VNO

III. Challenges

The Swivel Connector Production project presented significant learning opportunities for the new Vietnamese supplier.

At first, the factory was not familiar with the client’s tight process-control requirements. During the New Product Introduction (NPI) phase, VNO’s QA team worked side by side with the supplier’s engineers to meet the customer’s standards.

Over the course of seven months, the teams overcame multiple challenges, including:

- Material and cutting-tool control, ensuring consistent machining accuracy.

- CNC process optimization, stabilizing tolerance across large-volume production.

- Assembly setup and fixture design, improving fit and sealing.

- Approval of plating sub-contractor, verifying coating adhesion and corrosion resistance.

Each sample underwent multiple validation rounds, beginning with review by VNO’s ground engineering team in Vietnam, then cross-checked by China-based technical experts and QC laboratories. The final submission was approved by UK QA inspectors before customer dispatch.

This multi-stage collaboration proved essential in achieving the high level of quality required for global supply.

IV. Results

After multiple refinements, Swivel Connector Production successfully moved into mass production. The first purchase order of 57,000 pieces was issued to the Vietnamese supplier, marking a significant milestone for both the client and VNO.

Before and after comparision

1st Batch

Batch 2

Batch 3

IV. Result

As a result, the client now receives the same product quality and competitive pricing from Vietnam as they previously did from China—while reducing supply-chain risk and shipping time.

“VNO is not a trading company, we like to think of ourselves as an engineering one that not only help our customers with their supply chain, but also work along side with the local factories and help them join the international supply chain.

The concept of our business is simple, however, the execution of which is an art that we are so lucky to learn from our China and UK offices and their 25 years of hard work perfecting this art.”

“Daniel Pham – Operational Director”