I. Overview

This Rail Guard Manufacturing case study showcases how Vietnam Outsourcing (VNO) supported a global client specializing in railings, barriers, and transportation safety equipment. The customer also provides agricultural and industrial machinery, with a growing focus on safety equipment manufacturing for transport and construction sectors.

The product under development is a rail guard system, which includes metal railings and structural barriers designed to protect vehicles and pedestrians in industrial or agricultural environments. VNO worked closely with the supplier to ensure compliance with mechanical strength, corrosion resistance, and dimensional accuracy requirements.

II. Main Process

Cut steel tubes to precise lengths using automated saws to ensure consistent sizing.

Use CNC pipe-bending machines to form smooth curves and accurate angles for the rail guard frame.

Press both ends of each frame to achieve the correct shape and alignment before welding.

Weld all frame parts together under strict tolerance control to maintain the system’s stability and strength.

Drill vent holes along the frame to allow air and moisture to escape during the hot-dip galvanizing process.

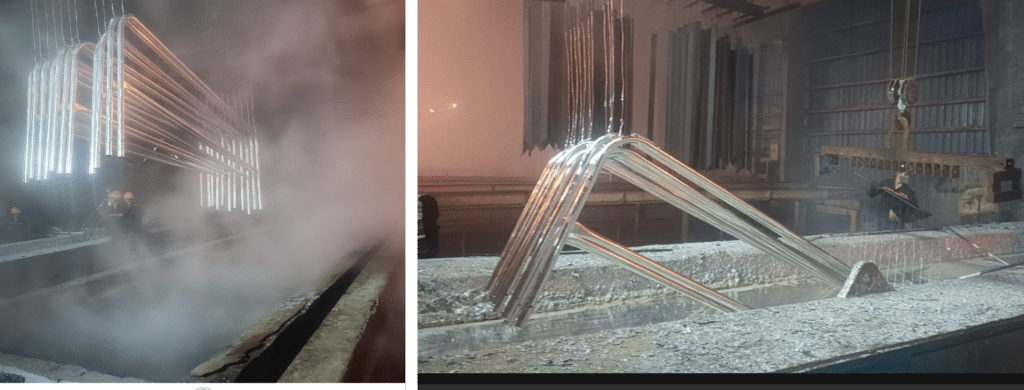

Immerse each unit in molten zinc to create a durable anti-corrosion coating, ensuring long-term outdoor performance.

Finally, inspect the finished rail guard for weld quality, surface coating, and dimensional conformity before packaging for export.

III. Detail process

III. Challenges

The Rail Guard Manufacturing process faced several challenges related to coating and material handling. Because the pipes were tall and had few drainage holes, airlocks formed during hot-dip galvanizing. As a result, each pipe required deep-tank immersion, which significantly increased processing time.

Additionally, ensuring even zinc coating on large rail guard frames was complex, especially when balancing production speed with coating uniformity.

IV. Solutions

To overcome these challenges, VNO and the supplier implemented several practical improvements:

- First, VNO searched for a supplier with a larger, deeper galvanizing tank capable of handling the full rail guard frame length without compromising coating quality.

- Next, the factory fabricated adjustable brackets to tilt the frames during submersion. This adjustment allowed air vent holes to remain at the top position, preventing trapped air pockets during the galvanizing process.

- Finally, consistent monitoring and quality checks ensured the galvanized coating met international corrosion-resistance standards, improving both production efficiency and product longevity.

V. Summary

Throughout the Rail Guard Manufacturing project, VNO maintained close communication with the client via Granchat, providing weekly updates that included progress reports, quality assessments, and real production images.

As a result, the client could monitor performance in real time, which helped streamline approvals and improve transparency. Both the technical and procurement teams appreciated this process and approved subsequent purchase orders before the first shipment was even completed.

The supplier’s leadership also worked proactively with VNO to ensure the rail guard systems met all customer expectations in terms of technical specifications, coating quality, and delivery schedule. Their cooperative attitude and fast implementation contributed to a successful long-term partnership.