Overview of the Plastic Hydrocyclone Manifolds Project

This Plastic Hydrocyclone Manifolds case study highlights how Vietnam Outsourcing (VNO) partnered with a global leader in liquid-solid separation, dewatering, and waste management equipment to develop precision plastic manifolds for demanding industrial environments.

The client produces crushers, feeders, separators, and filtration systems used in mining and wastewater applications. For this project, they required high-performance Plastic Hydrocyclone Manifolds made of PU (polyurethane) — a material known for its durability, elasticity, and chemical resistance under pressure.

VNO selected a Vietnamese supplier with proven experience in plastic, silicone, and rubber manufacturing. The factory specialized in casting, molding, and injection processes for customized industrial components. This was their first project involving PU plastic casting, representing a major step forward in technology adoption and material control.

Plastic Hydrocyclone Manifolds Manufacturing Process

PU Casting Process

1 – Mold Design and Fabrication

The engineering team designed a mold based on the customer’s 3D drawings and sample parts. The mold incorporated tolerances and venting channels to prevent air entrapment during casting.

2 – Material Preparation

Technicians mixed the raw PU materials and bonding agents before heating and liquefying the mixture to achieve optimal flow properties.

3 – Casting and Curing

The molten polyurethane was poured into the prepared molds. After casting, each part was cured in a furnace at 120°C for 2 hours to ensure full polymerization and mechanical strength.

4 – Quality Control

Inspection covered:

Dimensional measurement with precision tools

Mechanical and physical property testing

Assembly and functionality verification

5 – Packaging and Shipment

All qualified parts were cleaned, labeled, and packed securely for international delivery.

Stainless steel clamp component.

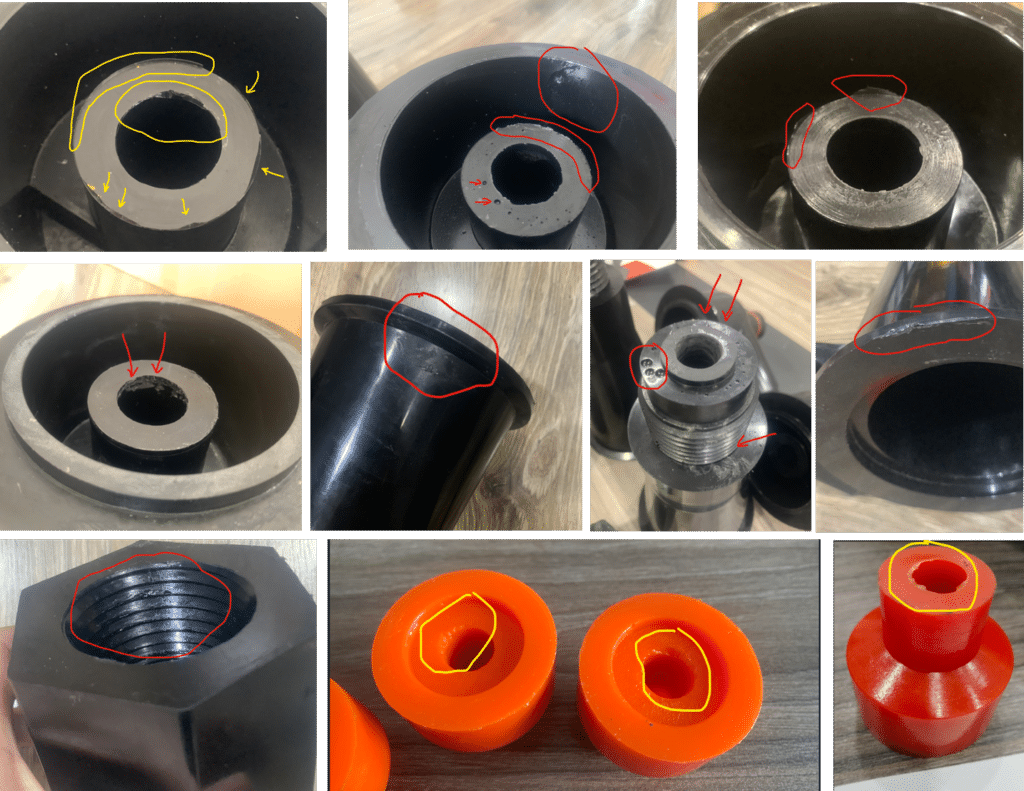

Challenges in Plastic Hydrocyclone Manifolds Manufacturing

This component operates under extreme conditions and high pressure. The assembly features and the mechanical properties of the materials used are critical to the product’s performance. The product is constructed and modeled based on the actual sample you provided, which has led to some unforeseen developments and challenges during the design process:

1. Assembly Issues

Description of the Issue: The assembly is loose and misaligned, affecting the sealing integrity of the product when operating under high pressure.

Solution: The supplier has accounted for tolerance levels during the mold fabrication process. Therefore, adjustments have been made to the mold to ensure that the dimensions related to the assembly position meet the assembly specifications of the sample you provided.

2. Reverse Threading and Loose Assembly

Description of the Issue:

Reverse threading or looseness in assembly affects both the assembly features and the operational functionality of the product.

Solution:

- Verify that the threading on the nut component is acceptable.

- Adjust the mold for the threaded section of the main body to ensure the correct thread orientation and increase the thread crest diameter to match the actual sample you provided.

3. Visual Defects

Description of the Issue:

Flash, insufficient plastic, chipping.

Solution:

- First, request the supplier to inspect and adjust the casting conditions and temperature to ensure proper material flow and fill.

- Then, during the final visual inspection stage, establish clear inspection standards and provide detailed guidelines for trimming the flash, so the finished parts achieve consistent surface quality.

Results and Project Outcome

After extensive testing and several process adjustments, the supplier successfully produced the Plastic Hydrocyclone Manifolds, meeting all dimensional and mechanical requirements. As a result, the team achieved several key improvements in product quality and manufacturing performance:

Key Achievements:

Firstly, engineers optimized the mold design to improve PU material flow.

Secondly, they resolved the threaded assembly issue, ensuring perfect alignment and secure fitting.

Next, the production team enhanced and standardized the surface quality across all units.

Finally, the factory established stable production for the first batch, marking a major step toward consistent mass manufacturing.

“This is the NCC product line’s first venture into PU plastic. We hope to continue collaborating with VNO to address outstanding quality issues and maintain stability. There is an opportunity to expand our export market. Additionally, we look forward to further collaboration and the development of other product models in the future, following the successful development and mass production of the 4″ model.”

“Customer review”