Green

Overview of the Large Sphere Metal Stamping Project

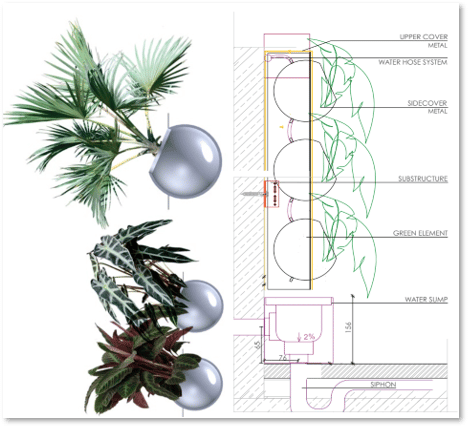

This Large Sphere Metal Stamping case study showcases how Vietnam Outsourcing (VNO) partnered with Green Urban Life, an interdisciplinary team integrating architecture, art, botany, and technology to design sustainable buildings covered with greenery.

The project required deep drawn stainless-steel sphere components (200mm and 300mm in diameter), which are part of an innovative automatic watering system for green architecture façades. Each sphere demanded precise sheet metal forming, laser cutting, welding, and assembly processes to meet both structural and aesthetic standards.

VNO supported the client from design verification through mass production, ensuring every phase — from prototype to shipment — followed strict quality and delivery targets.

Large Sphere Metal Stamping Process

Challenges in Large Sphere Metal Stamping

Producing large stainless-steel spheres through metal stamping presented several technical challenges.

Deformation Control:

During deep drawing, deformation can easily occur, especially with stainless steel’s low elongation and high hardness. Experienced engineering oversight was essential to maintain uniform curvature.

Surface Scratches:

Because the product required a smooth reflective surface, preventing scratches became a top priority. Standardizing handling and polishing steps was key to maintaining high aesthetic quality.

Stress Marks and Cracks:

The forming process can introduce internal stress, leading to small fractures. Minimizing this required deep understanding of material behavior during deformation.

VNO’s Solutions for Large Sphere Metal Stamping

Deformation Reduction:

Stainless steel has a limited elongation range and a high hardening index, which can lead to cracking during forming. VNO engineers applied pre-weld temperature control, used optimized die geometry, and adjusted drawing speed to reduce stress concentration.

We also considered austenitic stainless-steel properties, which undergo a phase transformation during deformation, forming brittle martensite. By carefully managing forming pressure, we minimized this transformation and prevented cracking.

Scratch Prevention:

Material selection was equally important. Our team recommended 1Cr18Ni9Ti or SUS304Cu stainless steel, both of which exhibit higher ductility and lower surface sensitivity during deep drawing. This significantly improved the forming yield and surface finish quality.

Stress Mark Elimination:

To further enhance results, we used dry lubricant coatings on die surfaces. This reduced friction between the die and material, allowing the sheet to flow smoothly through the forming zone. The dry film barrier also protected against sticking and surface damage, producing a cleaner, high-quality finish.

Project Results and Achievements

After implementing these measures, VNO achieved 98% quality acceptance across all production batches.

The project confirmed that Vietnam-based suppliers can meet complex Large Sphere Metal Stamping demands for architectural and design applications.

We would like to further expand our cooperation, because we are also

planning to establish the ideas and products of Green urban Life on the Asian market.

We think Hanoi could be a very good starting point.

~ Johannes Leitner ~