Overview of the Ammunition Packaging Project

This Ammunition Packaging case study highlights a UK-based defense packaging supplier expanding its production to Vietnam to diversify supply chains amid global uncertainty.

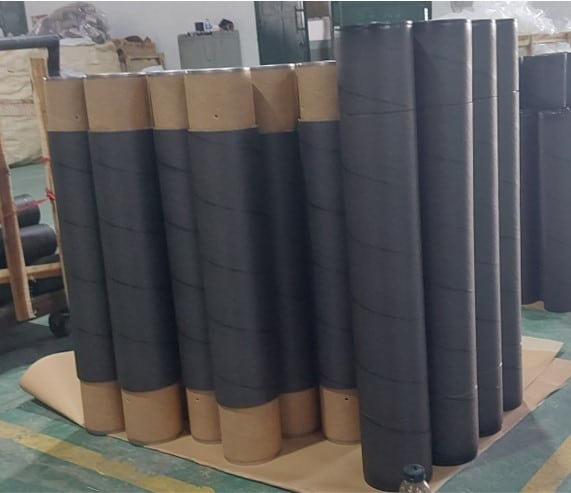

The core product — a fiber tube for ammunition packaging — required full MIL-standard compliance to ensure safety, durability, and reliability. Partnering with Vietnam Outsourcing (VNO), the client aimed to localize production while maintaining the same high standards used in their European facilities.

VNO worked closely with the supplier to adjust production techniques, train workers, and optimize factory management. The result was a smooth transfer of technology and an on-time delivery that met every quality requirement.

Ammunition Packaging Manufacturing Process

Kraft paper, aluminum foil, polycoat, polylaminate, polyvinyl acetate, and asphalt glues were processed and cut to precise dimensions.

Each fiber tube was wound according to its structural construction and thoroughly dried to ensure uniform strength and moisture resistance.

Metal subcomponents were punched and bent using custom molds, while plastic parts were created through injection molding to achieve accurate fits.

All parts were assembled, followed by First Article Tests (FAT) and detailed inspections before final packing and shipment.

Detail Workflows with VNO

Step 101

Qualified 100% IQC Material Inspection (Inspection level Importance ) Unqualification Review & Disposition

Step 2 (PQC)02

Kraft, aluminum foil, polycoat, polylaminate, polyvinylaxetate and asphalt glues – Split to small dims

Step 3 (PQC)03

Winding – following to each construction requirement of fiber tube and drying

Step 4 (PQC)04

Punching and bending mold metal subcomponents – Injection mold plastic

Step 5 (PQC)05

Assembly

Step 6 (PQC)06

Qualified FAT Inspection

Step 707

Write series number on out box & packing

Challenges

High-level management system

The key challenge in this Ammunition Packaging project was aligning Vietnam’s factory systems with the rigorous MIL standards required for defense-grade production.

High-Level Management Standards:

The project demanded strict documentation, traceability, and cross-departmental quality control — all new to the local supplier.

Technology & Equipment Gaps:

Some production machinery and management systems did not initially meet MIL criteria, requiring process adaptation and equipment calibration.

Skill and Experience Limitations:

The supplier’s workforce lacked prior exposure to defense manufacturing. VNO bridged this gap by providing three months of hands-on engineering training and technical guidance before prototype approval.

Results of the Ammunition Packaging Project

After several production trials, VNO successfully delivered a finished fiber tube that met all Ammunition Packaging specifications.

Through consistent supervision, process upgrades, and continuous quality improvement, the supplier achieved compliance with MIL standards and gained valuable know-how in defense packaging production.

Outcome Highlights:

- First prototype delivered within project timeframe.

- Full MIL-standard compliance achieved.

- Sustainable production process established in Vietnam.

- Strengthened supplier capability for future defense projects.

Conclusion

This Ammunition Packaging case study demonstrates how Vietnam Outsourcing (VNO) transforms local capabilities into globally recognized standards. By bridging the gap between advanced engineering requirements and Vietnam’s production potential, VNO enables international defense suppliers to scale safely, reliably, and cost-effectively.