Case study

Real Projects That Prove Vietnam’s Engineering Capability

Vietnam is becoming one of Asia’s most reliable manufacturing destinations. Over the last decade, local factories have built strong production systems, improved equipment, and trained skilled workers. As a result, more global companies now choose Vietnam for quality, cost control, and long-term growth.

At Vietnam Outsourcing (VNO), we help businesses build lasting partnerships with trusted Vietnamese suppliers. Through hands-on engineering support and strict on-site quality control, we make sure every project runs smoothly. These Vietnam manufacturing case studies show how we combine experience, precision, and teamwork to help clients succeed.

Precision & Metal Fabrication Projects

Explore our advanced metal fabrication capabilities — Discover how VNO supports global partners in welding, machining, and heavy structure manufacturing across Vietnam.

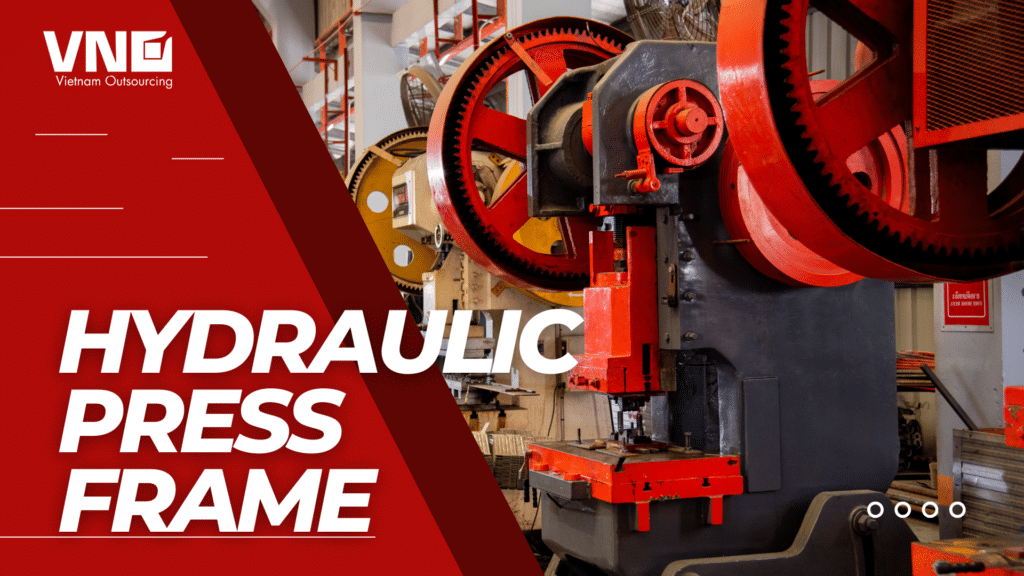

Hydraulic Press Machine Frame Manufacturing

VNO partnered with two leading European manufacturers to localize hydraulic press machine frame production in Vietnam. Together, we improved CNC machining, oil tank testing, and large-frame assembly. As a result, the supplier achieved accurate tolerances and reliable delivery performance.

👉 Read the full case study: Hydraulic Press Machine Frame

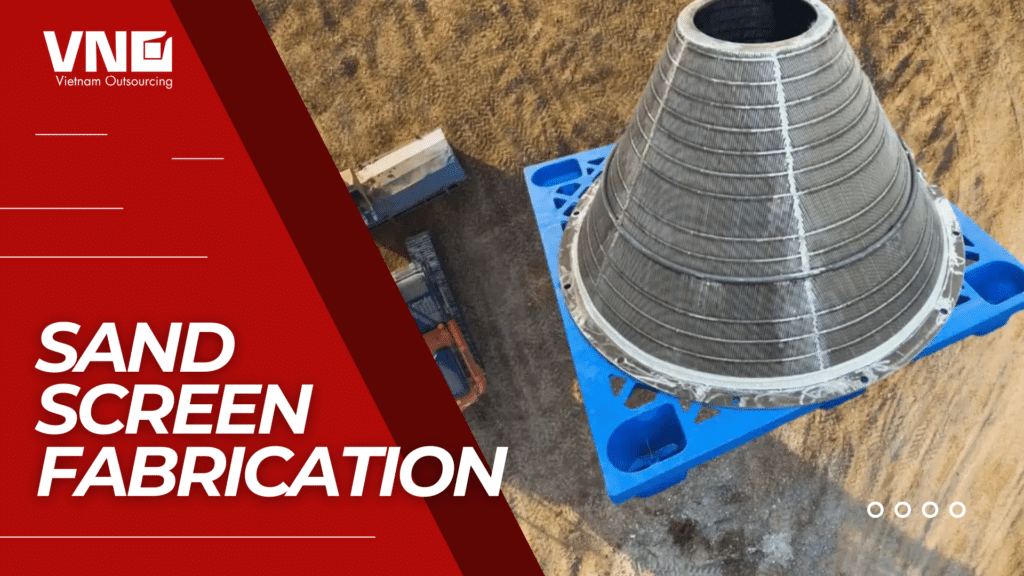

235-Inch Sand Screen Manufacturing

In this project, VNO worked with a local precision metal supplier to produce 235-inch stainless-steel sand screens for the oil and gas industry. The process involved tube forming, multi-stage welding, and anti-corrosion finishing. After several trials, each unit passed pressure and dimensional inspections, proving Vietnam’s ability to handle large-scale metal fabrication with confidence.

👉 Read the full case study: 235-Inch Sand Screen Manufacturing

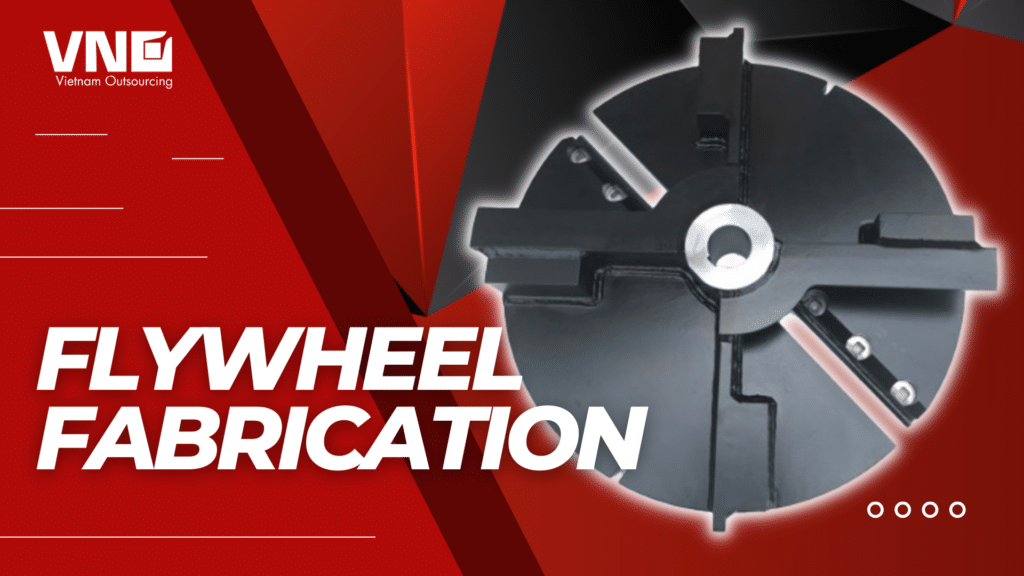

Flywheel Fabrication for Woodworking Machinery

A British machinery brand collaborated with VNO to produce complex flywheels requiring laser cutting, CNC machining, and balancing. During the project, we refined tooling alignment and process setup. Consequently, the supplier delivered stable quality and smooth operation at high speeds.

👉 Read the full case study: Flywheel Fabrication

Main Chutes Fabrication for Concrete Mixers

For a U.S. construction equipment company, VNO coordinated main chute fabrication through bending, rolling, and welding. In addition, we implemented PPAP level III documentation to strengthen traceability and ensure export compliance.

👉 Read the full case study: Main Chutes Fabrication

Rail Guard System Manufacturing

VNO also managed rail guard manufacturing for a transport safety project. We improved pipe bending, structural welding, and galvanizing processes. As a result, the supplier boosted production speed while maintaining strict quality standards.

👉 Read the full case study: Rail Guard System

Military & Defense Packaging Projects

See how VNO helps international defense suppliers meet MIL standards through precision fabrication, metal forming, coating, and quality assurance.

Ammunition Packaging – Fiber Tube Project

A U.K. defense supplier worked with VNO to develop fiber tube components for ammunition packaging. Together, we adjusted local production methods and provided on-site training to achieve full MIL compliance.

👉 Read the full case study: Ammunition Packaging (Fiber Tube)

Vietnam Ammunition Box (PA171)

VNO collaborated with a Vietnamese factory to manufacture metal ammunition boxes using stamping, welding, and powder coating. Every box passed pressure and leak testing, ensuring durability and air-tight performance. In the end, the project delivered export-level quality on time.

👉 Read the full case study: Vietnam Ammunition Box (PA171)

Construction Equipment Projects

From roofing components to green architecture, VNO supports clients with innovative metal forming and stamping solutions built to last.

Roof Jack Manufacturing

VNO supported an American construction brand in starting roof jack production in Vietnam. By refining press tooling and forming techniques, the supplier achieved consistent output and lower manufacturing costs. Consequently, production became faster and more stable.

👉 Read the full case study: Roof Jack Manufacturing

Large Sphere Metal Stamping for Green Urban Life

VNO teamed up with Green Urban Life to create deep-drawn stainless-steel spheres for urban architectural designs. With careful pressure adjustments and stress reduction methods, we minimized surface defects and achieved high visual precision.

👉 Read the full case study: Large Sphere Metal Stamping

Precision Machining & Component Manufacturing

Discover how VNO localizes precision machining and assembly processes in Vietnam, ensuring quality consistency for international OEMs.

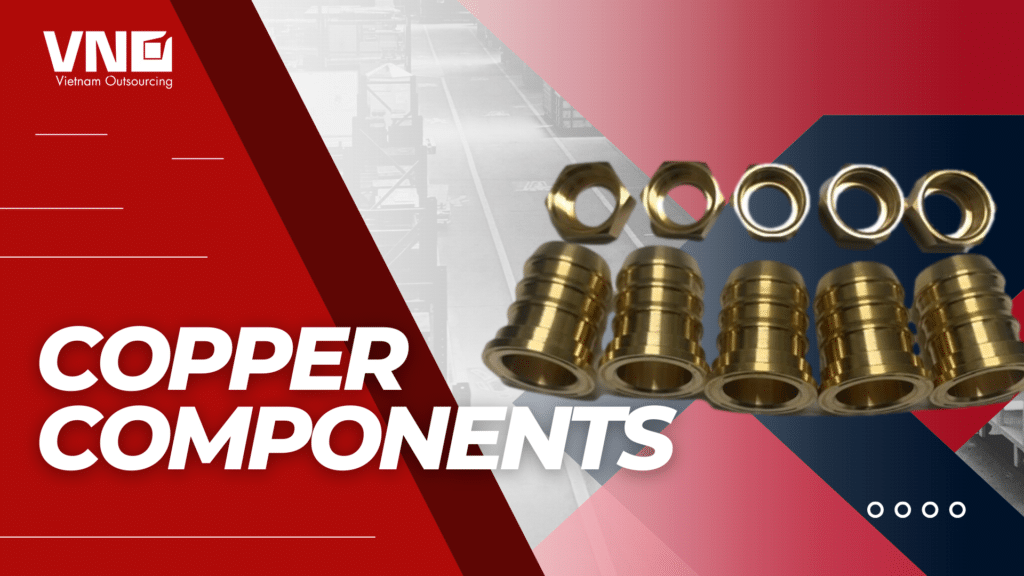

Sub Copper Components Outsourcing

VNO helped a U.K. water control company relocate copper component machining from China to Vietnam. We optimized threading, surface finishing, and packaging. Moreover, we aligned the supplier’s quality system with international requirements.

👉 Read the full case study: Sub Copper Components Outsourcing

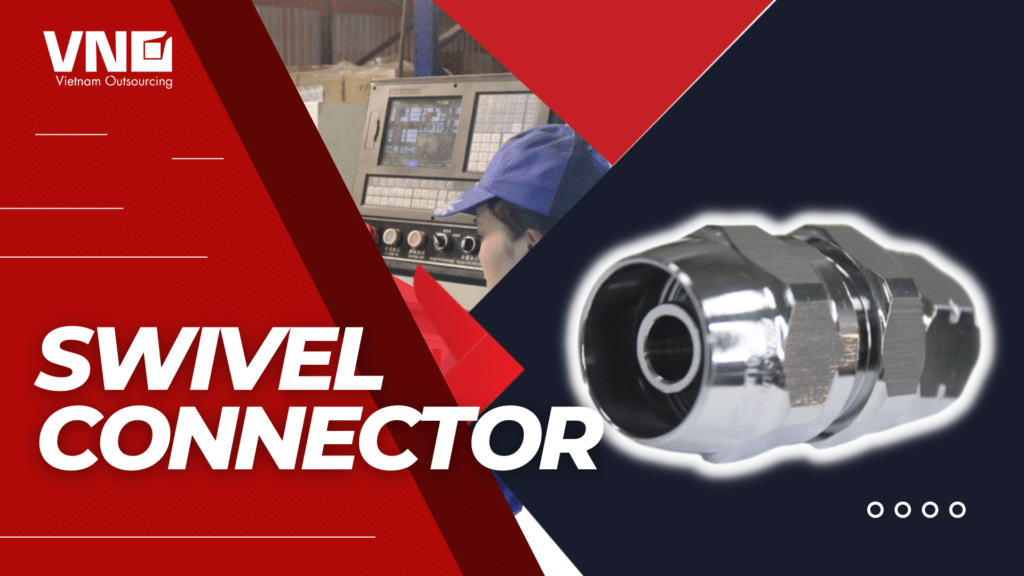

Swivel Connector Production

VNO also assisted a fluid control client with swivel connector production through hot forging, CNC machining, and plating. It took several prototype rounds and seven months of close collaboration, but the supplier reached stable mass production with consistent results.

👉 Read the full case study: Swivel Connector Production

Plastic & Composite Component Projects

Vietnam’s plastics and polymer sector is evolving fast. See how VNO supports industrial clients with PU casting, molding, and precision assembly.

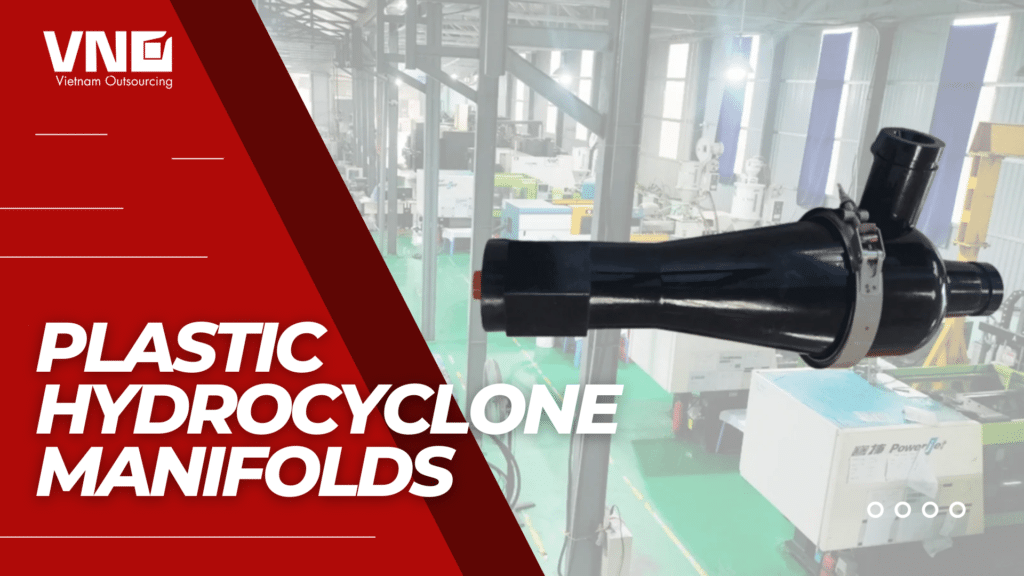

Plastic Hydrocyclone Manifolds

VNO collaborated with a global separation technology company to produce PU plastic manifolds. From mold design to casting and curing, our engineers supervised every stage. Finally, the product passed all mechanical and dimensional tests, confirming Vietnam’s capacity for complex plastic components.

👉 Read the full case study: Plastic Hydrocyclone Manifolds

Engineering Excellence Behind Every Project

Each of these Vietnam manufacturing case studies highlights VNO’s strength as both an engineering and outsourcing partner. Our specialists work directly with factory engineers to improve efficiency, minimize waste, and ensure consistent quality.

Because we follow ISO 9001, ISO 14001, and IATF 16949 standards, every project meets international expectations. Furthermore, our cross-border coordination model allows smooth communication between clients and suppliers, reducing delays and misunderstandings.

Why Choose Vietnam for Manufacturing

Vietnam continues to attract investors because it offers a balance of quality, cost, and scalability.

Competitive Cost: Save up to 40% compared with China and India.

Skilled Workforce: Over 70% of citizens are working age and technically trained.

Trade Access: 17 active Free Trade Agreements open doors to major global markets.

Stable Growth: Manufacturing contributes over 25% to Vietnam’s GDP, driven by rising FDI.

Altogether, these Vietnam manufacturing case studies prove that Vietnam has become a strong, sustainable, and forward-looking manufacturing hub for international partners.