Introduction

Hydraulic engineering drives countless industries, and outsourcing production can unlock huge benefits. Among global destinations, Vietnam stands out as a reliable hub for hydraulic pump manufacturing. With its skilled workforce and modern factories, the country offers companies an edge in both cost and quality.

Why Outsource Hydraulic Pumps to Vietnam?

The benefit of outsourcing to Vietnam lies in striking the right balance: lower costs without reduced standards. Labor expenses are 30–40% lower than in many Western countries, while access to advanced machinery ensures efficiency. This combination allows companies to protect margins and still deliver reliable, high-performing pumps to customers.

You might also want to know more about Steel fabrication in Vietnam

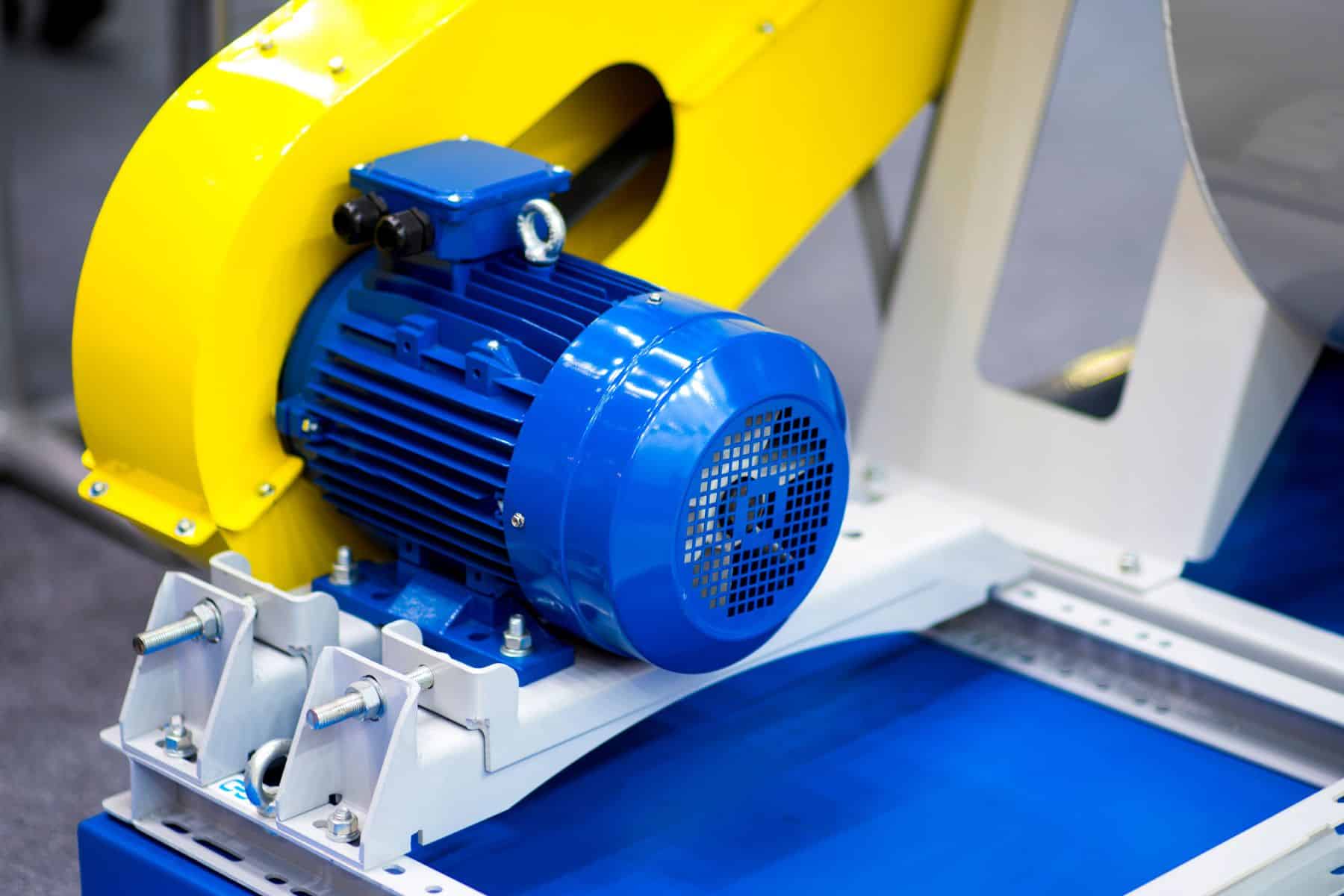

Skilled Workforce and Modern Technology

Vietnam’s workforce is highly trained in precision machining and assembly. Engineers and technicians operate high-pressure casting machines, CNC equipment, and automated assembly lines. As a result, manufacturers can produce pumps that meet strict international standards. The integration of Industry 4.0 tools further enhances accuracy, speed, and cost savings.

Choosing a Reliable Hydraulic Pump Manufacturer

To succeed in outsourcing, companies must choose the right partner. Look for manufacturers with:

-

A strong reputation and proven track record.

-

Compliance with certifications like ISO 9001 and IATF 16949.

-

Transparent quality control systems, including raw material checks and final product testing.

These factors ensure that every hydraulic pump meets performance and durability expectations.

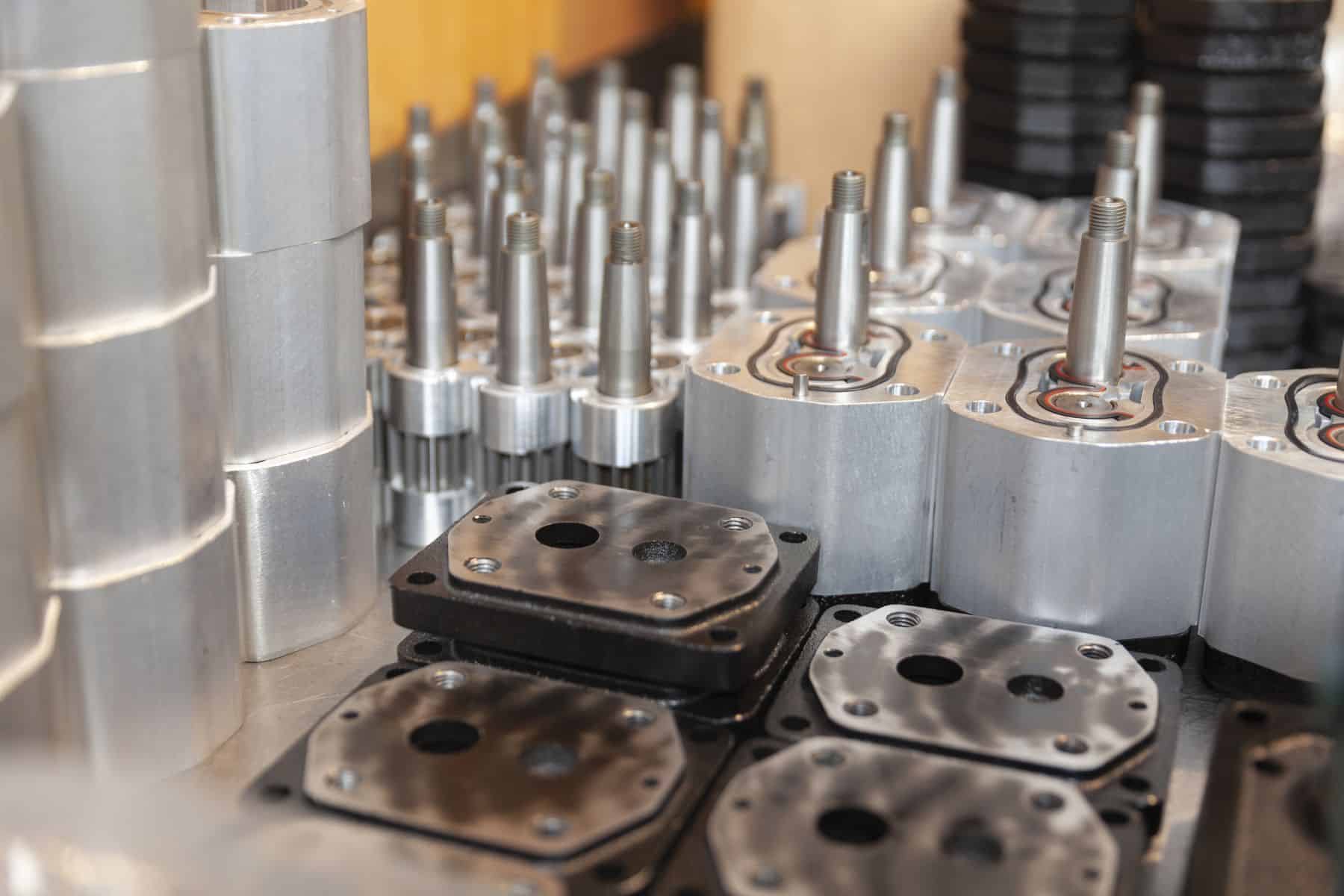

How Vietnam Manufactures Hydraulic Pumps

The art of production blends tradition with advanced technology. Each component is machined to exact specifications before skilled technicians assemble the pumps. Every step demands precision—from aligning small components to sealing the final product. This careful process guarantees performance and reliability.

Quality Control in Vietnamese Factories

Quality control is strict. Inspections occur at every stage, from material selection to final testing. Many factories use automated inspection tools alongside manual checks. Defects are detected early, ensuring that only pumps meeting international benchmarks are shipped.

Case Studies: Global Success

-

VN Nasa reduced production costs by partnering with Vietnamese manufacturers while maintaining top-tier quality. Their move streamlined operations and expanded their market reach.

-

Prominent Vietnam collaborated with local factories to enhance product quality. The result: stronger, more durable pumps and higher customer satisfaction.

Communication and Project Management

Outsourcing succeeds when communication is clear. Regular updates, transparent timelines, and quick responses build trust between partners. Strategic project management adds another layer of control. By setting milestones, monitoring progress, and solving issues early, companies can ensure efficiency and quality.

Conclusion

Outsourcing hydraulic pump production to Vietnam delivers both savings and reliability. The skilled labor force, advanced metal fabrication, and strict quality standards create an ideal environment for global businesses. Companies gain access to precision products while building strong partnerships in a growing market.

Looking for a trusted partner in Vietnam? Contact Vietnam Outsourcing (VNO) today to explore customized hydraulic pump solutions.