Introduction

How can you guarantee CNC machines quality control when your service provider is located on the other side of the world? This is a common challenge for businesses outsourcing prototypes, small-batch components, or large production runs. If you are working with a third-party partner for CNC machining in Vietnam, ensuring quality is not optional—it’s critical.

In this guide, we highlight five key factors that determine the quality of outsourced machining services. Use these as a checklist to quickly identify reliable partners and avoid costly mistakes.

1. Certificates Are Essential

The first step in CNC machines quality control is reviewing certifications. At minimum, your supplier should hold ISO 9001, which sets requirements for quality management systems. Depending on your project, you may also need certificates such as ISO/TS 16949 (automotive), AS9100 (aerospace), or ISO 13485 (medical devices).

If a supplier can show valid certifications, you can move to the next step: checking their equipment.

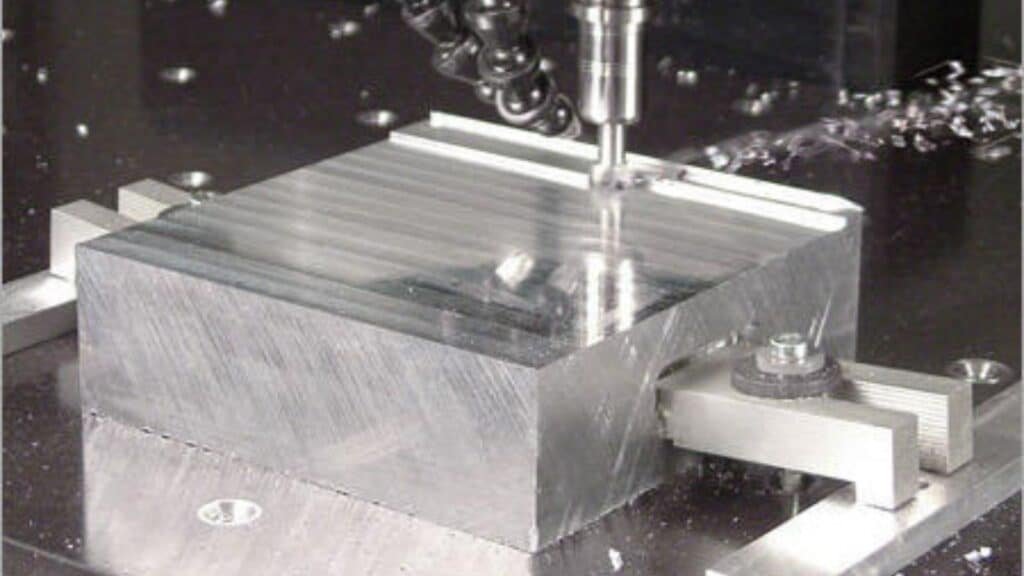

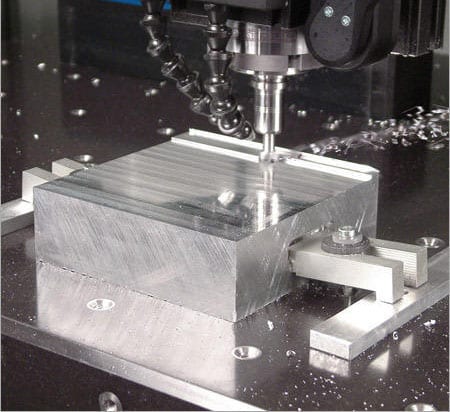

2. Machine Types Influence Quality

Not all CNC machines are equal. The equipment your supplier uses directly affects the precision and finish of your parts.

-

2–3 axis machines: Good for simple shapes.

-

4 axis machines: Allow more flexibility for multi-side machining.

-

5 axis CNC machines: Handle complex geometries, provide superior accuracy, and reduce setups.

When evaluating a service provider, match their machine capability with the complexity of your design. However, advanced machines alone do not guarantee success—it also depends on who operates them.

3. Skilled Operators Make the Difference

Even the best equipment fails without qualified operators. Many failed projects result from lack of skill or poor operator training rather than machine defects.

Therefore, a trustworthy provider should:

-

Employ experienced machinists.

-

Maintain strict operator training programs.

-

Enforce internal quality management systems.

A shop that invests in its people as much as its machines is far more likely to deliver consistent results.

4. Internal Quality Inspections

Prestigious CNC service providers maintain their own quality inspection systems. These often include:

-

Raw material inspection – Ensuring supplier reliability and checking every batch of incoming material.

-

Operator inspection and training – Monitoring operator performance and upgrading skills through training.

-

Internal Quality Control (IQC) department – A dedicated team that verifies parts at every stage of production.

The presence of a well-structured IQC department is a strong indicator that a company takes CNC machines quality control seriously.

Conclusion

By checking certifications, evaluating machine capability, verifying operator skills, and confirming quality inspection processes, you can confidently choose a reliable partner for your CNC projects.

At Vietnam Outsourcing (VNO), we combine certified processes, modern CNC equipment, and experienced operators to guarantee world-class machining results. With over 4.5 million parts shipped annually to global customers, we ensure your projects meet expectations in terms of quality, cost, and delivery.

Ready to secure high-quality precision machining components? Contact VNO today for trusted CNC machining solutions.