- September 9, 2025

- Daniel Pham

Sheet Metal Cutting in Vietnam

Table of Contents

Introduction to Sheet Metal Cutting in Vietnam

Sheet metal cutting is one of the most essential processes in modern manufacturing. From automotive and aerospace to construction and electronics, the demand for precise cutting solutions continues to grow. In recent years, Vietnam has emerged as a competitive hub for sheet metal cutting services, thanks to its skilled workforce, advanced machinery, and cost advantages compared to traditional markets like China and India.

At Vietnam Outsourcing (VNO), we help U.S. and EU clients connect with trusted Vietnamese factories specializing in sheet metal cutting and related fabrication processes. Our engineering expertise ensures that every project meets international standards for quality, consistency, and compliance.

Key Sheet Metal Cutting Techniques in Vietnam

Vietnamese metal forming manufacturers offer a wide range of cutting technologies tailored to diverse project requirements. Some of the most common include:

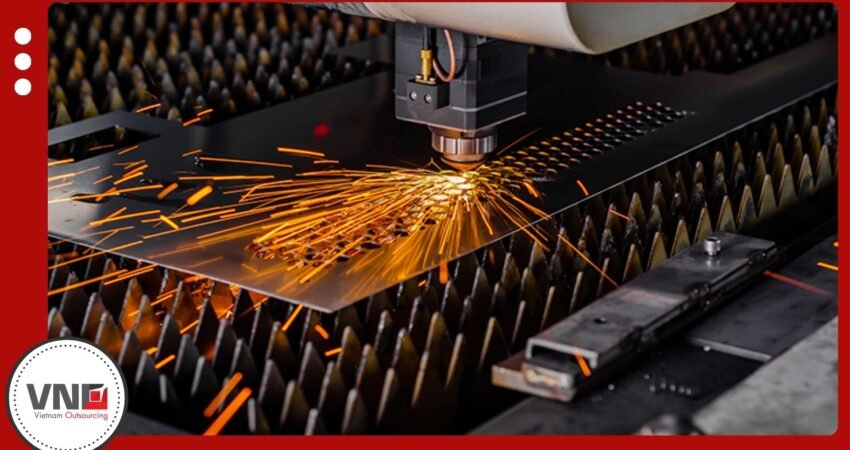

Laser Cutting

Laser cutting provides high accuracy and clean edges, making it suitable for intricate designs and tight tolerances. Many factories in Vietnam use CNC laser machines to cut stainless steel, aluminum, and mild steel sheets with precision.

Plasma Cutting

For thicker materials, plasma cutting is a cost-effective option. Vietnamese workshops apply plasma systems to produce strong, durable parts for construction equipment, machinery, and heavy-duty components.

Waterjet Cutting

Waterjet technology is gaining popularity for cutting materials without heat distortion. It is ideal for aerospace and electronics industries, where precision and material integrity are critical.

Mechanical Cutting (Shearing & Punching)

Traditional methods like shearing and punching remain widely used for high-volume production. These processes offer efficiency for simple shapes and mass-produced sheet metal parts.

Benefits of Sheet Metal Cutting in Vietnam

Outsourcing sheet metal cutting to Vietnam provides several strategic advantages for international buyers:

- Cost Efficiency: Lower labor and operational costs compared to Western markets.

- Advanced Technology: Increasing adoption of CNC laser and automation systems.

- Skilled Workforce: Technicians trained to meet ISO and ASTM quality standards.

- Flexible Production: From small batches to mass production with quick turnaround.

- Supply Chain Resilience: Vietnam serves as a strong China+1 alternative for diversification.

Applications of Sheet Metal Cutting Across Industries

Vietnamese sheet metal cutting services support a wide range of industries:

- Automotive: Body panels, brackets, and custom metal components.

- Electronics: Enclosures, heatsinks, and precision casings.

- Construction: Roofing sheets, ventilation ducts, and safety equipment.

- Aerospace & Defense: High-precision parts that meet international compliance.

- Agricultural Machinery: Durable frames, guards, and functional components.

Quality Standards and Compliance

Most Vietnamese manufacturers adhere to international certifications such as:

- ISO 9001 for quality management.

- RoHS and REACH for environmental compliance.

- ASTM and EN standards for material quality and durability.

VNO ensures that partner factories maintain strict quality control at every stage of sheet metal cutting, from raw material selection to final inspection.

Why Choose Vietnam Outsourcing (VNO)

As a liaison partner, Vietnam Outsourcing (VNO) bridges the gap between global buyers and Vietnamese suppliers. Our team of engineers provides:

- Technical support in product design and prototyping.

- Supplier audits and compliance checks.

- Transparent communication and project management.

- Cost-effective solutions tailored to international clients.

You might also want to know how US client benefit from Battery Housing Outsourcing or Guard Rail Outsourcing

Conclusion

Sheet metal cutting in Vietnam is gaining global recognition for its combination of quality, efficiency, and affordability. With diverse cutting technologies, compliance with global standards, and a strong supply chain, Vietnam is becoming a go-to destination for businesses seeking reliable manufacturing partners.

Looking for a trusted partner in sheet metal cutting? Contact Vietnam Outsourcing (VNO) today for high-quality solutions tailored to your needs.