Introduction

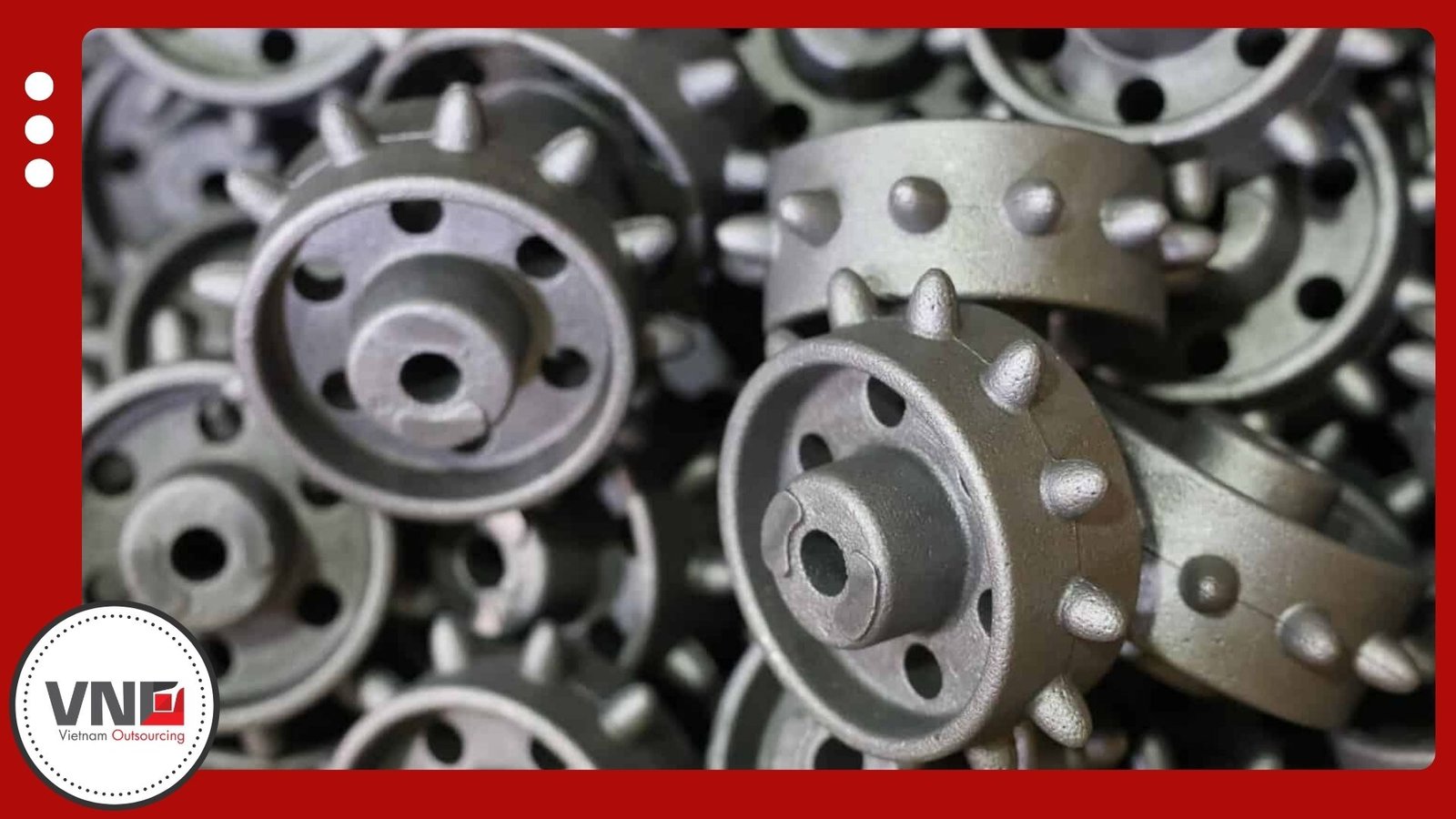

Sand casting products in Vietnam play a vital role in the country’s growing manufacturing sector. As one of the oldest and most versatile casting methods, sand casting allows manufacturers to produce metal parts in a wide range of sizes and shapes. From components as small as 56 grams to massive castings weighing several tons, this process provides flexibility for both small and large-scale industries.

Vietnam has developed into a reliable hub for sand casting thanks to its skilled workforce, competitive costs, and modernized foundries. Local manufacturers combine traditional expertise with upgraded equipment to deliver castings that meet international standards.

Range of Sand Casting Products

The diversity of sand casting products in Vietnam is remarkable. Smaller items include gears, pulleys, crankshafts, rods, and rotors. Larger castings range from heavy machinery containers to automotive engine blocks, cylinder heads, and transmission frames. Sand molds can be customized for both intricate details and bulky parts, which keeps this method relevant across industries.

Characteristics of Sand Casting Products

Sand casting provides several key characteristics:

- Ability to create very large parts.

- Flexibility for complex shapes and internal cavities.

- Wide choice of materials, from cast iron and steel to aluminum and copper alloys.

- Lower tooling cost compared to permanent molds or die casting.

- Recyclable scrap metal, reducing waste and costs.

- Shorter lead times for prototypes or small batches.

Advantages of Sand Casting in Vietnam

Producing sand casting products in Vietnam offers clear advantages:

- Competitive pricing: Vietnam’s labor and production costs remain lower than many neighboring countries.

- Skilled workforce: Foundry workers combine hands-on craftsmanship with training in modern techniques.

- Growing industry base: Industrial zones and supply chains support large-scale casting and exports.

- Export potential: Vietnam die casting supplier already serves automotive, construction, and heavy machinery markets in the US, EU, and Japan.

Limitations of Sand Casting Products

Sand casting also has its limits:

- Surface finish is rougher compared to die casting or investment casting.

- Dimensional accuracy can vary, often requiring machining to meet tight tolerances.

- Defects such as porosity may occur if mold preparation is inconsistent.

Vietnamese foundries are improving these areas by adopting better molding practices, advanced inspection systems, and international quality certifications like ISO 9001 and ASTM.

Applications of Sand Casting Products

Industries rely heavily on sand casting for essential components:

- Automotive: Engine blocks, cylinder heads, transmission housings.

- Construction: Pipes, valves, and structural supports.

- Marine: Propellers, pump housings, rotors.

- Machinery: Gearboxes, heavy frames, containers.

- Energy: Turbine and generator parts.

This versatility makes sand casting indispensable where durability and custom design are required.

Conclusion

Sand casting products in Vietnam combine flexibility, cost efficiency, and reliability. While the process may not always match the precision of die casting, it excels in producing large and complex parts at affordable prices. With Vietnam’s skilled workforce and strong export capacity, the country stands out as a trusted source of sand castings for global buyers.