- September 11, 2025

- Daniel Pham

Safety Anchor Outsourcing: Why Vietnam Is the Right Choice

Table of Contents

Introduction

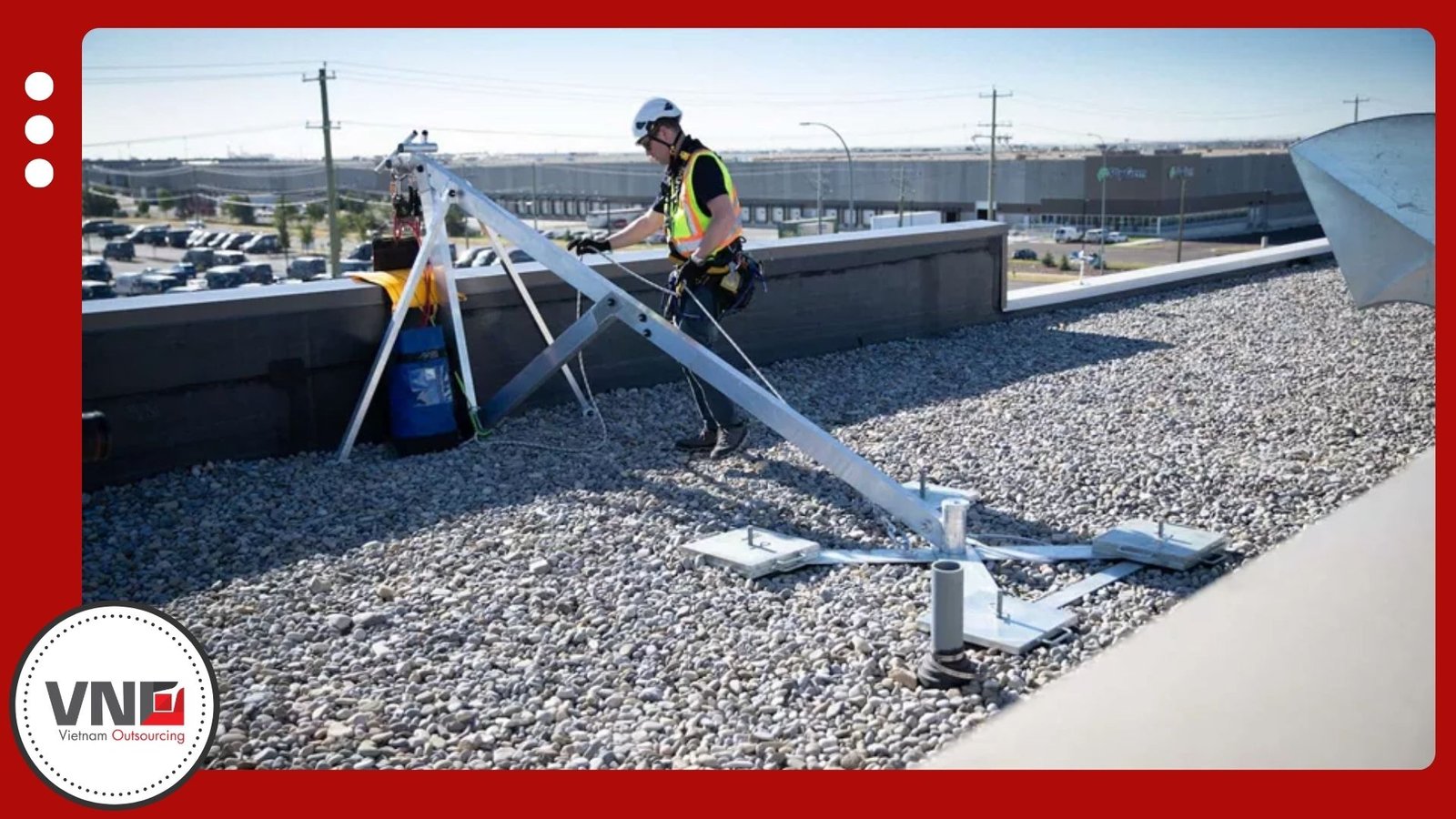

In construction, infrastructure, and industrial projects, safety anchors play a critical role in fall protection and structural security. As global demand for reliable safety systems rises, many companies turn to safety anchor outsourcing to balance cost, quality, and supply chain efficiency.

Vietnam has quickly become a competitive hub for manufacturing safety equipment. With modern production capabilities, skilled labor, and competitive costs, Vietnam safety anchor manufacturing is now attracting buyers from the U.S., EU, and Asia-Pacific.

Technology in Safety Anchor Manufacturing

Safety anchors must withstand extreme loads and comply with stringent international safety standards. To achieve this, leading manufacturers in Vietnam employ advanced technologies such as:

- CNC machining for high-precision components and mounting hardware.

- Metal forming and forging to create strong, durable anchor bodies.

- Robotic welding systems to ensure consistent quality and structural integrity.

- Hot-dip galvanizing and powder coating for corrosion resistance and long-term durability.

- Laser marking for product traceability and compliance labeling.

These technologies allow Vietnam safety anchor suppliers to produce a wide range of anchors, including roof anchors, wall anchors, and custom-engineered safety systems.

Quality Control in Safety Anchor Outsourcing

Because safety anchors are life-critical products, quality control is a top priority in outsourcing. Reliable suppliers in Vietnam follow strict quality assurance protocols, including:

- Compliance with ISO 9001, CE, and EN standards for safety equipment.

- Raw material inspections to verify steel and alloy strength.

- Load testing and pull-out tests to confirm anchor performance under stress.

- Surface treatment inspections for coating thickness and corrosion resistance.

- Batch traceability and documentation for international buyers who require full certification.

By outsourcing to Vietnam, buyers gain access to anchors that meet or exceed international safety requirements, ensuring both compliance and peace of mind.

Choosing the Right Partner

Not all suppliers are equal. When considering safety anchor outsourcing, companies should carefully evaluate potential partners based on:

- Technical expertise – Ability to produce a wide variety of anchor designs with precision.

- Certifications – Availability of CE, EN, or OSHA-compliant testing and documentation.

- Production capacity – Flexibility to handle both small orders and large-scale projects.

- Experience – Proven track record in serving international construction and safety markets.

- After-sales support – Ongoing customer service, replacement parts, and warranty management.

Selecting the right partner minimizes risk, improves product quality, and ensures timely delivery. You might also want to know more about Roofing Outsourcing and Battery Housing Outsourcing

Why Vietnam for Safety Anchor Outsourcing?

Vietnam has become a trusted destination for outsourcing due to several competitive advantages:

- Lower production costs: Vietnam offers affordable manufacturing without compromising safety or quality.

- Modern infrastructure: Suppliers invest in CNC machining, galvanizing, and robotic welding equipment.

- Skilled workforce: Engineers and technicians are trained to operate advanced manufacturing systems.

- Global trade access: Free trade agreements with the U.S., EU, and Asia-Pacific markets reduce tariffs and streamline logistics.

- Proven export capability: Many Vietnam safety anchor suppliers already deliver products to international clients, meeting global standards.

These factors position Vietnam as a reliable source for safety anchors, balancing cost-efficiency with strict quality requirements.

Vietnam Outsourcing: Your Trusted Partner

At Vietnam Outsourcing (VNO), we help international buyers connect with certified Vietnam safety anchor suppliers. Our services include:

- A carefully vetted supplier network specializing in Vietnam safety anchor manufacturing.

- Local technical teams that oversee production and conduct in-factory inspections.

- Independent testing and verification before shipment to ensure compliance.

- Support for both OEM production and customized anchor solutions.

- Experience in managing projects for global clients across construction, energy, and industrial sectors.

By partnering with VNO, companies gain a reliable extension of their procurement team, ensuring that every safety anchor meets international performance and safety standards.

Conclusion

Safety anchor outsourcing provides businesses with a strategic way to reduce costs while maintaining product quality and compliance. With advanced technology, strong quality control, and competitive pricing, Vietnam safety anchor manufacturing offers a compelling solution for global buyers.

By working with Vietnam Outsourcing (VNO), you gain access to trusted suppliers, expert quality oversight, and a streamlined outsourcing process that ensures safety anchors meet the highest international standards.

Looking for a reliable partner in safety anchor outsourcing? Contact Vietnam Outsourcing (VNO) today to connect with certified suppliers in Vietnam.