Introduction to Precision Machining in Vietnam

Precision Machining in Vietnam has become one of the fastest-growing sectors in the country’s manufacturing industry. With rising global demand for CNC machining and high-quality machined components, Vietnam has positioned itself as a reliable hub for international buyers. Companies from the U.S., Europe, and Asia increasingly source machined parts from Vietnam due to its combination of advanced technology, skilled labor, and competitive pricing.

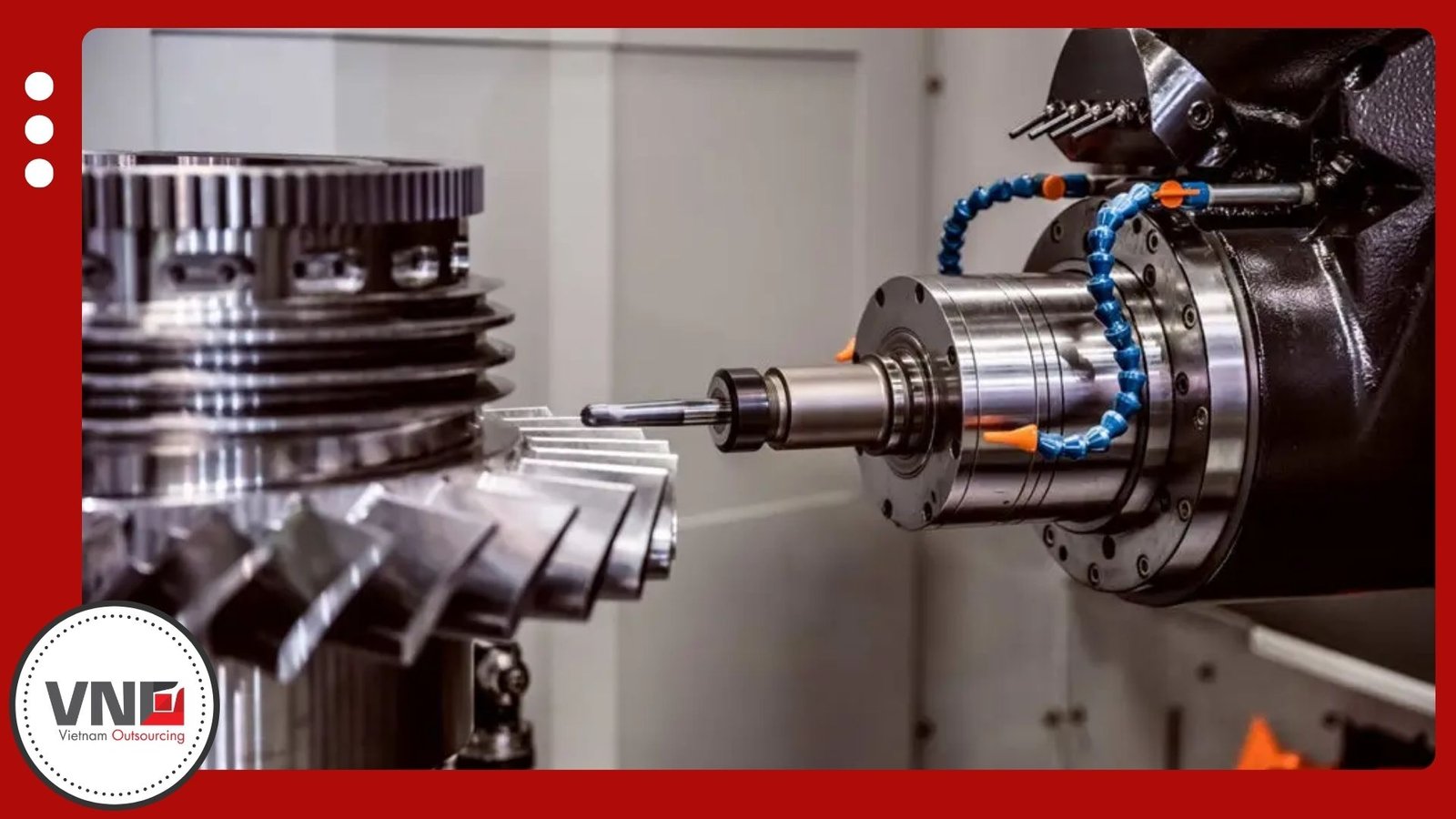

Vietnam CNC machining services are known for their ability to produce complex parts with tight tolerances, meeting international standards across industries such as aerospace, automotive, electronics, medical devices, and industrial machinery. By outsourcing to Vietnam, buyers gain access to modern facilities, ISO-certified processes, and a strong supply chain network that supports both low-volume prototypes and high-volume production runs.

Why Choose Precision Machining in Vietnam

Precision Machining in Vietnam offers a unique mix of advantages that set it apart from other manufacturing destinations.

Skilled Workforce and Technical Expertise

Vietnam has developed a strong pool of engineers and technicians with expertise in CNC programming, CAD/CAM design, and advanced machining operations. This ensures consistent quality in Vietnam machined components, from small intricate parts to large-scale industrial products.

Competitive Costs Without Compromising Quality

Vietnam CNC machining provides cost savings of 20–30% compared to suppliers in China, while still meeting global quality standards. This makes outsourcing to Vietnam a strategic choice for businesses seeking both affordability and reliability.

Advanced Machinery and Technology

Modern factories in Vietnam are equipped with CNC milling, CNC turning, EDM, grinding, and multi-axis machining centers. These facilities can handle complex geometries, tight tolerances, and specialized surface finishes, making Vietnam machined components highly competitive in global markets.

Compliance with International Standards

Precision Machining in Vietnam aligns with strict quality certifications such as ISO 9001, ISO/TS 16949, and AS9100 for aerospace. Many suppliers also adopt RoHS and REACH compliance, ensuring safe and sustainable production practices.

Quality Standards in Vietnam CNC Precision Machining

Factories offering Precision Machining in Vietnam operate under strict international standards to guarantee consistency, safety, and global compliance. By following these certifications, Vietnam CNC machining suppliers ensure that machined components meet the requirements of demanding industries such as aerospace, automotive, and medical devices.

Common Standards and Certifications Applied

- ISO 9001 – Quality Management System for consistent production processes and customer satisfaction.

- ISO/TS 16949 (IATF 16949) – Automotive sector standard ensuring defect prevention and continuous improvement in production.

- AS9100 – Aerospace industry certification covering safety, reliability, and traceability of parts.

- ISO 13485 – Required for medical device components, ensuring compliance with strict regulatory requirements.

- RoHS and REACH – Environmental and chemical safety standards ensuring materials are free from hazardous substances.

- ASTM and DIN Standards – Applied for material properties, machining tolerances, and testing requirements to meet international benchmarks.

Applications of Vietnam CNC Machining

Vietnam CNC machining services cover a wide range of industries. Key applications include:

- Aerospace: High-strength, lightweight machined components for aircraft structures and engines.

- Automotive: Precision parts such as engine housings, transmission systems, and brackets.

- Medical Devices: Surgical instruments, implants, and diagnostic equipment with high accuracy.

- Electronics: Machined enclosures, connectors, and cooling systems for sensitive equipment.

- Industrial Equipment: Hydraulic press frames, main chutes, and custom machine parts.

With this broad range of applications, Precision Machining in Vietnam continues to attract global buyers seeking high-quality outsourcing options.

Vietnam Machined Components and Surface Finishes

Machined components in Vietnam are not only accurate but also versatile in finishing options. Depending on project requirements, suppliers offer:

- Anodizing (Type II, Type III)

- Powder coating

- Zinc plating

- Sandblasting

- Polishing and brushing

- Heat treatment for durability

These finishing techniques ensure that Vietnam machined components meet both functional and aesthetic requirements, ready for direct use or further assembly.

The Role of Vietnam Outsourcing Partners

Many international buyers rely on trusted partners to connect with Vietnam CNC machining suppliers. Outsourcing specialists act as a bridge between buyers and local factories, providing:

- Supplier qualification and audits

- Engineering support and design optimization

- Quality inspection and compliance checks

- Logistics and shipping coordination

Working with a partner ensures smooth operations, reduces risks, and enhances efficiency for businesses sourcing precision machining in Vietnam.

Future of Precision Machining in Vietnam

The outlook for Precision Machining in Vietnam is highly positive. As global manufacturers diversify supply chains away from single-country dependence, Vietnam has emerged as a top choice. Continuous investment in technology, training, and infrastructure strengthens the sector’s competitiveness.

With increasing automation, digitalization, and adoption of Industry 4.0 practices, Vietnam CNC machining providers are set to deliver even higher value to international clients in the coming years.

Q&A on Precision Machining in Vietnam

Industries such as aerospace, automotive, medical devices, electronics, and industrial equipment benefit the most due to Vietnam’s ability to meet tight tolerances and international standards.

Vietnam offers more competitive pricing than China while maintaining higher consistency than India. Its growing industrial base makes it a preferred choice for Western buyers.

Yes, most suppliers comply with ISO 9001, ISO/TS 16949, AS9100, and RoHS standards, ensuring quality and safety for international use.

Lead times typically range from 3–6 weeks depending on part complexity, volume, and finishing requirements. Prototyping services can be delivered faster.

The best approach is to work with outsourcing specialists who conduct supplier audits, verify certifications, and manage logistics to ensure seamless operations.