- September 9, 2025

- Daniel Pham

Metal Forming Outsourcing in Vietnam

Table of Contents

Introduction

Metal forming outsourcing has become a critical strategy for global manufacturers seeking cost-effective, high-quality production. By working with trusted partners overseas, companies in the U.S., EU, and other regions can access advanced forming processes without heavy capital investment. As supply chains diversify away from China, Vietnam is emerging as one of the most reliable hubs for metal forming outsourcing.

Types of Metal Forming Processes

When outsourcing, manufacturers typically choose among several forming techniques depending on the product’s complexity, material, and end-use requirements.

- Metal Stamping – Ideal for high-volume production of precision parts, from automotive components to consumer electronics housings.

- Forging – Produces extremely strong parts for industries such as aerospace, construction equipment, and energy.

- Deep Drawing – Common in manufacturing of automotive body parts, kitchen sinks, and enclosures requiring thin yet durable walls.

- Roll Forming – Used to create long, consistent profiles such as channels, frames, and beams in construction and transportation.

- Spinning – Best suited for round or conical parts like cookware, lampshades, and aerospace components.

Each process requires specialized equipment, technical knowledge, and strict quality control systems, making outsourcing a strategic choice for many companies.

Benefits of Metal Forming Outsourcing

Outsourcing metal forming brings multiple advantages to businesses aiming to stay competitive.

- Cost Efficiency

- Lower labor costs compared to Western countries.

- Competitive raw material pricing and optimized factory operations.

- Reduced capital expenditure, as outsourcing eliminates the need to invest in expensive forming machinery.

- Technical Expertise & Compliance

- Vietnam’s factories increasingly follow ISO, ASTM, and RoHS standards.

- Outsourcing partners offer engineering support to ensure design accuracy and product compliance with Western regulations.

- Faster Lead Times

- Modernized production lines and growing industrial zones in Vietnam enable quicker turnaround.

- Proximity to major shipping routes ensures reliable logistics.

- Scalability

- Easy to expand order volumes without additional in-house investment.

- Flexible capacity helps companies adapt to fluctuating market demand.

Key Industries

Metal forming outsourcing supports a wide range of industries that rely on durable, precision-engineered parts.

- Automotive – Body panels, engine components, chassis parts, and brackets.

- Construction Equipment – Heavy-duty frames, enclosures, and structural parts.

- Aerospace – High-strength, lightweight components meeting rigorous safety standards.

- Energy & Power Systems – Turbine components, power distribution equipment, and housings.

- Consumer Electronics – Casings, brackets, and frames for devices requiring mass production with consistency.

This diversity proves that outsourcing is not only about cost savings but also about meeting industry-specific technical demands.

Challenges and Solutions

While outsourcing offers clear benefits, companies must address common challenges.

- Quality Control – Without robust checks, outsourced products may not meet required tolerances. The solution is to work with partners who apply strict inspection protocols and international standards.

- Communication Barriers – Technical misunderstandings can delay production. Partnering with outsourcing companies that provide bilingual engineering support ensures clarity.

- Logistics & Tariffs – Fluctuating tariffs and transport costs can impact pricing. Vietnam’s favorable trade agreements and negotiation capabilities help mitigate these risks.

Why Vietnam for Metal Forming Outsourcing?

Vietnam is quickly becoming a preferred location for metal forming outsourcing, and for good reason.

- Cost Advantage vs. China & India – Competitive labor costs and transparent operations make Vietnam an attractive alternative.

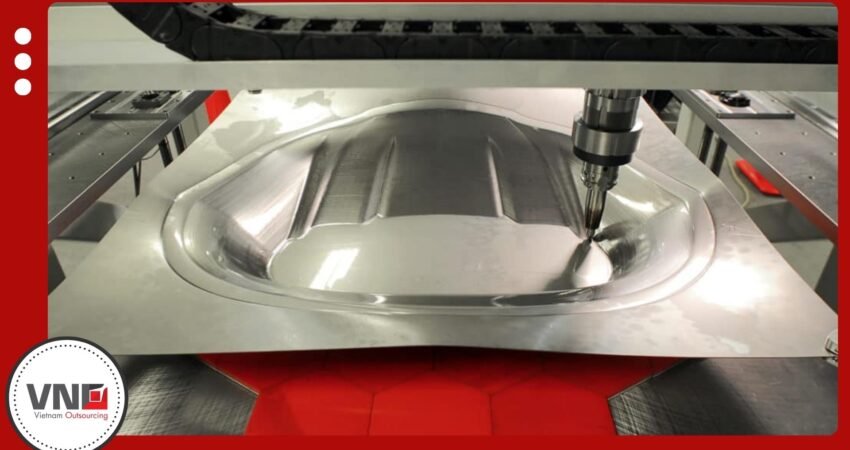

- Skilled Workforce & Modern Factories – Thousands of factories specialize in forming processes with increasingly advanced CNC and automated lines.

- Stable Supply Chain – Vietnam’s manufacturing zones offer diversified suppliers, reducing dependency risks.

- Compliance & Trust – Many Vietnamese suppliers have adapted to meet the quality expectations of U.S. and EU buyers, providing ISO-certified and audited facilities.

VNO’s Role in Metal Forming Outsourcing

At Vietnam Outsourcing (VNO), we bridge the gap between Western buyers and trusted Vietnamese factories. Our role is threefold.

- Supplier & Buyer Partner – Acting as both a technical partner for Western clients and a buyer for local factories.

- Engineering Expertise – Our in-house engineers ensure products meet international standards before shipment.

- Risk Mitigation – We handle quality control, compliance checks, and communication, giving clients confidence in every order.

With years of experience serving U.S. and EU clients, VNO ensures that metal forming outsourcing from Vietnam is not only cost-effective but also reliable and future-proof.

Conclusion

Metal forming outsourcing is no longer just a cost-cutting tactic; it is a long-term strategy to ensure competitiveness, compliance, and scalability in global manufacturing. With Vietnam emerging as a world-class hub, companies can gain both efficiency and quality by partnering with trusted outsourcing experts.

Looking to outsource your metal forming projects? Contact Vietnam Outsourcing (VNO) today for trusted, high-quality solutions.

Frequently Asked Questions (FAQs) about Metal Forming Outsourcing

1. What is metal forming outsourcing?

Metal forming outsourcing means hiring external suppliers to handle processes such as stamping, forging, or roll forming. As a result, companies save costs and improve efficiency without investing in expensive equipment.

2. Why do manufacturers choose metal forming outsourcing?

Manufacturers outsource to cut costs, scale production, and ensure compliance with global standards. Moreover, it gives them access to skilled labor and advanced technologies.

3. What industries benefit the most from metal forming outsourcing?

Automotive, aerospace, construction, energy, and consumer electronics benefit the most. For example, automotive firms need body panels, while aerospace requires lightweight yet strong parts.

4. Why is Vietnam a strong destination for metal forming outsourcing?

Vietnam offers lower costs than China and India, a skilled workforce, and ISO-certified factories. In addition, its stable supply chains and trade agreements provide reliable delivery.

5. How can companies ensure quality in metal forming outsourcing?

VNO connects global buyers with trusted Vietnamese factories. Furthermore, our engineers handle compliance, quality checks, and communication to ensure smooth, reliable production.