Introduction

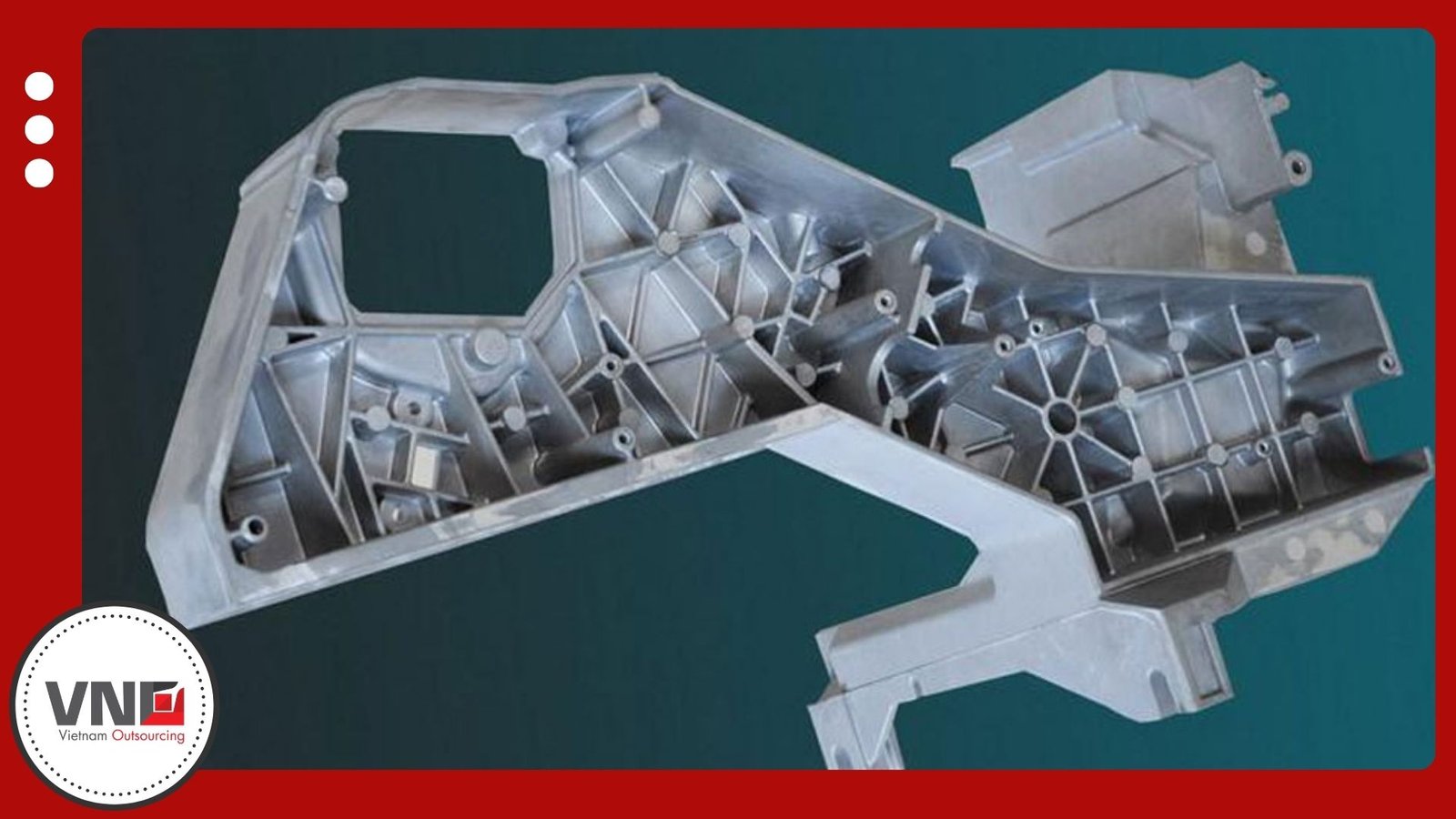

Low pressure casting is a metal casting method where molten metal is pressed into a mold using pressure ranging from 8 up to several hundred ata. This controlled pressure allows the alloy to fill the mold completely, producing parts with excellent mechanical strength, precision, and surface quality.

Advantages of Low Pressure Casting

Low pressure casting delivers several benefits compared to traditional methods:

-

High mechanical properties: The dense structure ensures stronger and more reliable castings.

-

High productivity: Manufacturers can achieve 100–200 castings per hour thanks to rapid filling and easy mechanization.

-

Precision and surface gloss: Casting accuracy can reach 0.01 mm, with both outer and inner surfaces highly polished.

-

Capability for thin and complex parts: This method produces thin-walled objects (>0.3 mm) and intricate parts such as holes with diameters of 1.5–3 mm.

-

Improved cooling and strength: Because metal molds are used, parts cool faster, which enhances durability and mechanical performance.

Disadvantages of Low Pressure Casting

-

The process cannot use sandblasting, so hole designs and inner surfaces must remain simple.

-

Molds wear out quickly due to constant exposure to high-pressure molten alloys.

-

The method is less suitable for ferrous metals because their high melting temperatures reduce mold durability.

Applications of Low Pressure Casting

-

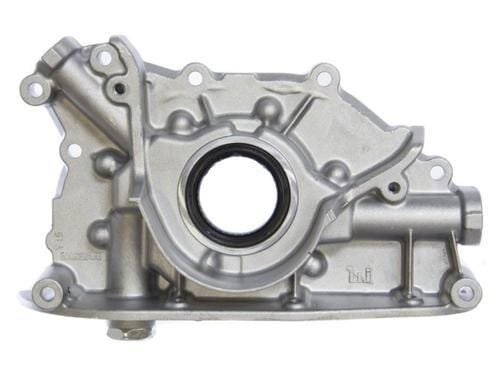

Oil pump casings

-

Pressure chamber caps

-

Air valves

-

Brass pipes and fittings

These applications highlight the method’s ability to deliver reliable components with high precision and excellent finish, which are very popular among Vietnam die casting supplier.

Conclusion

Low pressure casting is an advanced technique that combines accuracy, speed, and durability. While mold wear and material restrictions remain challenges, the process continues to be a preferred choice for producing complex non-ferrous components with superior quality. Beside this method, Vietnam suppliers also offer investment casting.