- March 3, 2025

- Daniel Pham

Incremental sheet forming in Vietnam: Cost & Precision

Table of Contents

Introduction: The Rise of Incremental Sheet Forming in Vietnam

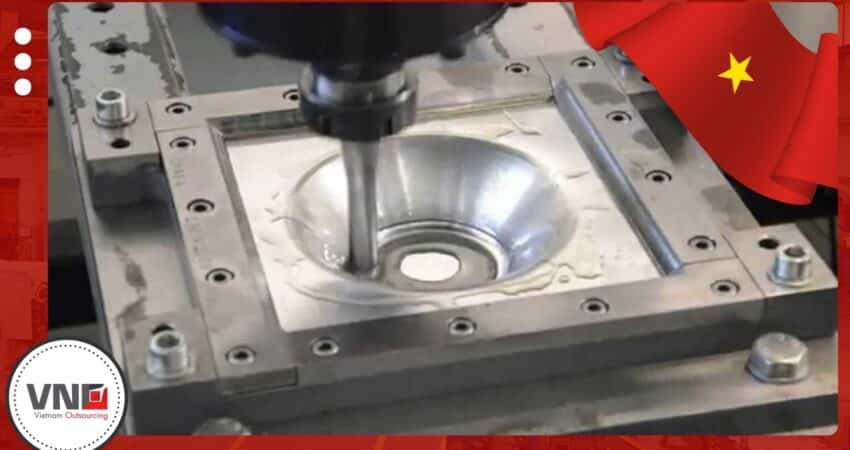

Incremental sheet forming is revolutionizing the metal forming industry by offering tailored fabrication and adaptive manufacturing solutions. Unlike traditional stamping and die-based forming, this advanced method allows for low-cost prototyping, small-batch production, and greater geometric complexity. As US and EU companies seek cost-efficient manufacturing, Vietnam has emerged as a leading outsourcing hub for progressive metal shaping due to its skilled workforce, lower operational costs, and investment in advanced metal fabrication technologies.

Why Vietnam is a Competitive Hub for Incremental Sheet Forming

1. Lower Production Costs & Skilled Workforce

Moreover, Vietnam provides affordable labor costs compared to China, India, and Western countries. This cost advantage, coupled with a highly skilled metalworking industry, allows businesses to achieve tailored fabrication without the high expenses associated with traditional forming techniques.

2. Flexible Fabrication with Advanced Technology

In addition, Vietnamese manufacturers utilize modern CNC-controlled progressive metal shaping machines to create custom metal components with minimal tooling investment. This technology enables:

- Greater design flexibility with complex geometries.

- Low-volume production capabilities without high initial costs.

- Quick prototyping and faster design modifications for industrial applications.

3. Reliable Material Sourcing & Trade Agreements

Furthermore, Vietnam has access to high-quality steel, aluminum, and other alloys through its strong trade partnerships. Additionally, free trade agreements (FTAs) such as EVFTA, CPTPP, and RCEP allow for lower tariffs and competitive export pricing, making Vietnam an attractive manufacturing partner for international companies.

Cost & Quality Benefits of Incremental Sheet Forming in Vietnam

1. Cost-Efficient Prototyping & Customization

Additionally, progressive metal shaping enables on-demand production and reduces the need for expensive dies and molds. This is particularly beneficial for:

- Aerospace and automotive industries requiring custom metal components.

- Medical device manufacturing where unique designs must be prototyped quickly.

- Architectural and industrial applications needing specialized metal fabrication.

2. High Precision & Reduced Material Waste

As a result, computer-controlled incremental forming, manufacturers achieve tight tolerances while minimizing material waste. Unlike traditional stamping, incremental forming only deforms the necessary areas, leading to a more sustainable and cost-effective production process.

3. Scalability for Low-Volume & Niche Production

Vietnamese factories cater to specialized industries by providing flexible production volumes, whether for small-batch prototypes or large-scale orders. The ability to scale production based on demand makes Vietnam an ideal outsourcing destination.

Trade Agreements & Export Benefits

Vietnam’s FTAs provide significant cost reductions for companies outsourcing progressive metal shaping:

- EU-Vietnam Free Trade Agreement (EVFTA): Eliminates tariffs on metal exports to the EU.

- Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP): Expands trade access to North America, Japan, and Australia.

- Regional Comprehensive Economic Partnership (RCEP): Strengthens supply chain networks across Asia-Pacific.

Consequently, these agreements help US and EU companies reduce logistics costs, increase profit margins, and improve supply chain efficiency.

Quality Control & Compliance in Vietnam’s Incremental Sheet Forming Industry

1. Compliance with International Manufacturing Standards

Vietnamese manufacturers follow strict quality control guidelines, including:

- ISO 9001 – Quality management systems.

- IATF 16949 – Automotive quality certification.

- ASTM and EN Standards – Compliance with industrial manufacturing requirements.

2. Strict Quality Assurance Measures

To ensure quality, manufacturers conduct comprehensive inspections to ensure product consistency and accuracy. These include:

- 3D scanning for dimensional accuracy.

- Material hardness and stress testing.

- Non-destructive testing (NDT) for critical components.

3. Skilled Workforce & Automation Integration

Thus, Vietnam’s metal forming industry benefits from ongoing technical training and automation advancements. With CNC integration, Vietnamese manufacturers maintain high efficiency and precision in progressive metal shaping.

Challenges & Considerations When Outsourcing Incremental Sheet Forming to Vietnam

1. Shipping & Logistics Considerations

Despite Vietnam’s cost savings, international buyers should consider shipping timelines:

- Sea freight to the US & EU takes 3-6 weeks.

- Airfreight is available for urgent orders but at a higher cost.

2. Supplier Selection & Manufacturing Consistency

Since not all manufacturers specialize in progressive metal shaping. US and EU buyers should:

- Conduct factory audits to assess technical capabilities.

- Verify material certifications to ensure compliance with industry standards.

- Partner with sourcing experts like Vietnam Outsourcing Pte Ltd to identify trusted suppliers.

3. Compliance with Import Regulations

To avoid legal issues, international companies must ensure compliance with customs regulations. Vietnam Outsourcing Pte Ltd provides support with:

- Trade compliance & export documentation.

- Supply chain management & quality assurance.

- Negotiating cost-effective contracts with manufacturers.

You might also want to know more about roll forming

FAQs: Incremental Sheet Forming in Vietnam

- Why is Vietnam a top choice for progressive metal shaping? Vietnam offers low production costs, skilled labor, and advanced CNC technology, making it a competitive alternative to China and India.

- What industries benefit most from progressive metal shaping? Aerospace, automotive, medical devices, and custom industrial applications rely on this technique for flexible and low-cost fabrication.

- What materials are commonly used in progressive metal shaping in Vietnam? Manufacturers work with stainless steel, aluminum, titanium, and specialized alloys.

- What are the typical shipping times from Vietnam to the US & EU? Sea freight takes 3-6 weeks, while airfreight is faster but more expensive.

- How can companies ensure quality control when outsourcing progressive metal shaping? Working with Vietnam Outsourcing Pte Ltd ensures access to vetted manufacturers, strict quality control, and optimized logistics.

Conclusion: Why Vietnam is the Future of Incremental Sheet Forming Outsourcing

With cost-effective production, advanced CNC technology, skilled labor, and strong trade agreements, Vietnam has positioned itself as a top destination for progressive metal shaping. As US and EU manufacturers seek adaptive manufacturing and tailored fabrication, Vietnam continues to deliver high-quality metal forming solutions at globally competitive prices.