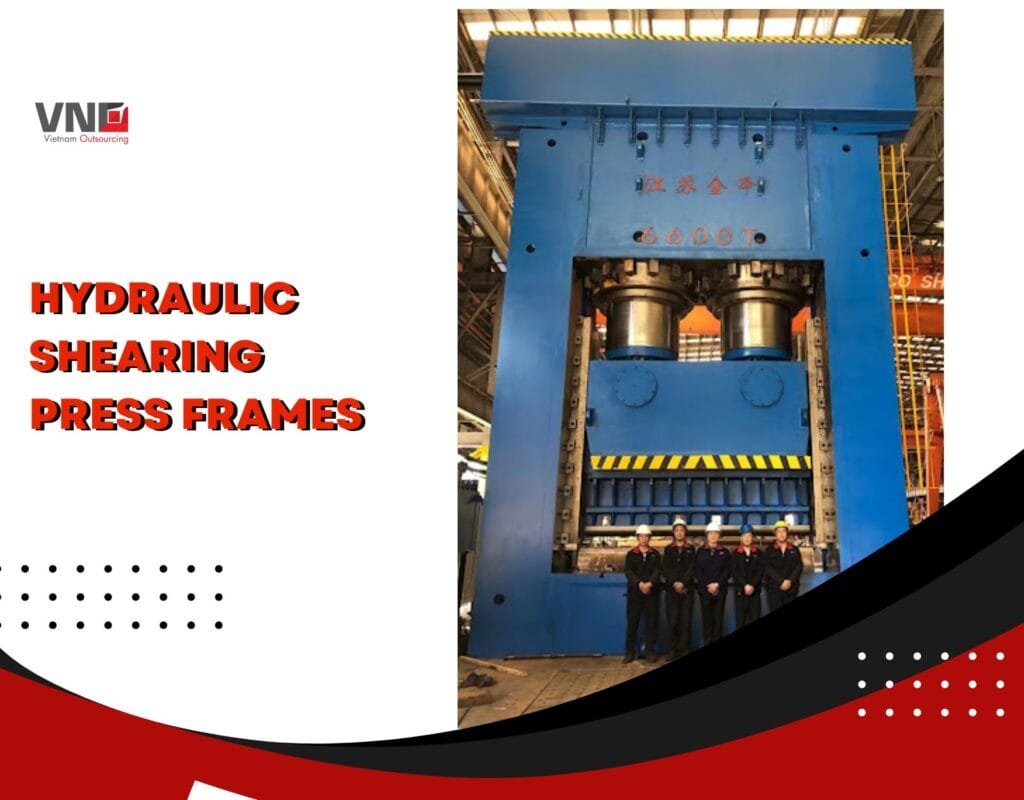

Overview of Hydraulic Shearing Press Frames

Hydraulic Shearing Press Frames play a central role in cutting sheet metal and plates. Using hydraulic force, they deliver clean and precise cuts. Frames are built with strong materials, allowing them to handle cutting forces from 50 to over 1,500 tons.

Their design ensures rigidity and durability, which reduces deflection during cutting. As a result, these presses maintain accuracy even under heavy loads, making them suitable for high-volume, high-tolerance tasks.

How Hydraulic Shearing Press Frames Work

The hydraulic system uses pressurized fluid to power the blade. That blade then cuts through metal, leaving straight and smooth edges. Because of this process, manufacturers can achieve both speed and precision.

Applications Across Industries

You might also want to know about Hydraulic Press Brakes

Metal Fabrication

In fabrication shops, hydraulic shearing frames cut sheet metal into required shapes and sizes. Machines can cut steel sheets up to 30 mm thick and 3 meters wide. For example, 600-ton frames are often used to meet strict quality standards.

Manufacturing

In general manufacturing, presses cut parts with accuracy and repeatability. This supports machinery production and ensures components fit perfectly. Frames with forces of around 800 tons are common in these environments.

Construction

Construction projects rely on hydraulic shearing presses for beams, columns, and plates. Frames with 1,200-ton capacities can cut heavy-duty steel while maintaining structural integrity.

Sheet Metal Industry

The sheet metal sector uses these presses for mass production. Frames between 500 and 1,000 tons cut sheets for appliances, HVAC, and consumer goods. High-speed cycles improve productivity without sacrificing accuracy.

Case Studies from Vietnam

Industrial Fabrication

A Vietnamese factory delivered frames with more than 1,000 tons of force for large-scale fabrication. These machines cut sheets up to 4 meters wide and 30 mm thick with consistent precision.

Automotive Components

In the automotive sector, a Vietnamese supplier provided 800-ton presses to a leading parts manufacturer. The machines cut with accuracy, helping ensure high-quality vehicle components.

Construction Projects

Vietnamese-built frames supported a high-rise project by cutting steel plates up to 50 mm thick. Their strength and precision guaranteed structural safety.

Sheet Metal Processing

A major appliance company sourced 600-ton presses from Vietnam. These frames cut large volumes of sheet metal quickly, boosting efficiency and reducing waste.

Why Source Hydraulic Shearing Press Frames from Vietnam?

Cost Savings – Vietnamese production is 20–30% cheaper than other regions.

Quality Standards – Suppliers follow ISO 9001 and ISO 14001 certifications.

Advanced Technology – CNC machining and robotic welding improve accuracy.

Customization – Frames tailored for force, size, and special features.

Fast Delivery – Lead times average 4–6 weeks, reducing downtime.

Conclusion

Hydraulic Shearing Press Frames are essential for precise metal cutting in fabrication, construction, automotive, and sheet metal industries. They combine strength, speed, and accuracy, enabling high-quality production.

Vietnamese manufacturers have proven their ability to deliver cost-effective and reliable shearing frames that meet international standards. For companies seeking efficiency and durability, sourcing from Vietnam is a strategic choice.

Looking for trusted Hydraulic Shearing Press Frames? Contact Vietnam Outsourcing (VNO) today for tailored solutions that enhance your production capacity.