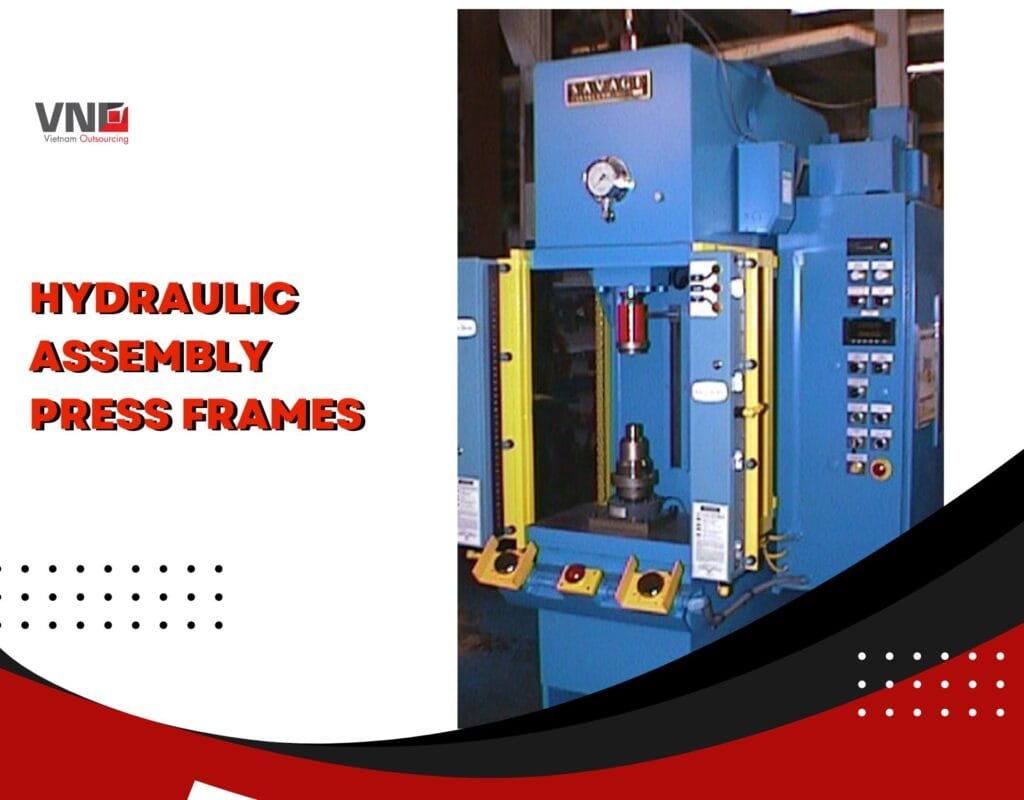

Overview of Hydraulic Assembly Press Frames

Hydraulic Assembly Press Frames are essential in operations requiring controlled force and precise alignment. These machines ensure components are fitted with consistency and durability. Built with strong frames and advanced hydraulic systems, they handle tasks ranging from delicate electronics to heavy automotive assemblies.

The global market for assembly presses is worth $5.8 billion, and it is projected to grow at a CAGR of 4.3% from 2024 to 2031. This expansion is driven by the rising demand for precision assembly in electronics and the steady growth of the automotive sector. Moreover, the need for reliable and efficient assembly solutions continues to push innovation in this field.

Applications of Assembly Press Machines

Electronics Industry

In electronics, manufacturers use these presses to assemble circuit boards and micro-components. Their micron-level accuracy ensures exact alignment. In addition, the controlled force prevents damage, which is vital for delicate parts.

Automotive Manufacturing

Automotive companies rely heavily on hydraulic presses to fit engine blocks, transmission parts, and other structural components. As a result, vehicles benefit from enhanced durability and consistent performance. Furthermore, these presses allow carmakers to maintain high-volume production while meeting strict quality standards.

Machinery and Equipment

In machinery, presses assemble gears, bearings, and other essential parts. Their adaptability supports multiple component sizes. Consequently, manufacturers gain flexibility and efficiency across different production lines.

Advantages of Hydraulic Assembly Systems

Accuracy – Maintains exact alignment, which is critical for sensitive applications.

Controlled Force – Applies pressure safely, therefore reducing the risk of damage.

Flexibility – Adapts to a wide variety of part sizes and materials.

In addition, these advantages make hydraulic assembly presses versatile tools that support both small-scale precision work and large industrial operations.

Sourcing Precision Press Frames from Vietnam

Vietnamese suppliers provide significant advantages for global buyers. First, their pricing is highly competitive, often 20–30% lower than other regions. Moreover, manufacturers in Vietnam combine affordability with advanced engineering.

Competitive Pricing – Lower production costs translate into savings without quality loss.

Engineering Excellence – CNC machining and robotic welding improve precision.

Quality Standards – Compliance with ISO 9001 and ISO 14001 ensures reliability.

Custom Solutions – Factories offer tailored dimensions and features to match client needs.

Fast Delivery – Short lead times, typically 4–6 weeks, help reduce downtime.

Vietnam Outsourcing’s Role

Vietnam Outsourcing (VNO) plays a key role in connecting buyers with trusted Vietnamese manufacturers. In addition, VNO provides engineering support, supplier management, and logistics services. As a result, international companies benefit from seamless sourcing of industrial assembly presses and metal fabrication that meet global standards.

Conclusion

Hydraulic Assembly Press Frames are vital for industries that require accuracy, controlled force, and versatility. From electronics to automotive and machinery, they ensure consistent results and support efficient production.

By sourcing from Vietnam, companies gain cost savings, advanced engineering, and international compliance. Moreover, with Vietnam Outsourcing as a partner, buyers secure dependable assembly solutions tailored to their specific needs.

Looking for precision-engineered Assembly Press Frames? Contact Vietnam Outsourcing (VNO) today.