Introduction

The hot chamber die casting machine is one of the most widely used systems in modern manufacturing. It is fast, efficient, and well-suited for metals with low melting points such as zinc, lead, and magnesium. Unlike cold chamber casting, the plunger of a hot chamber system sits directly in the furnace. As a result, molten metal flows vertically through the sprue into the mold with minimal handling.

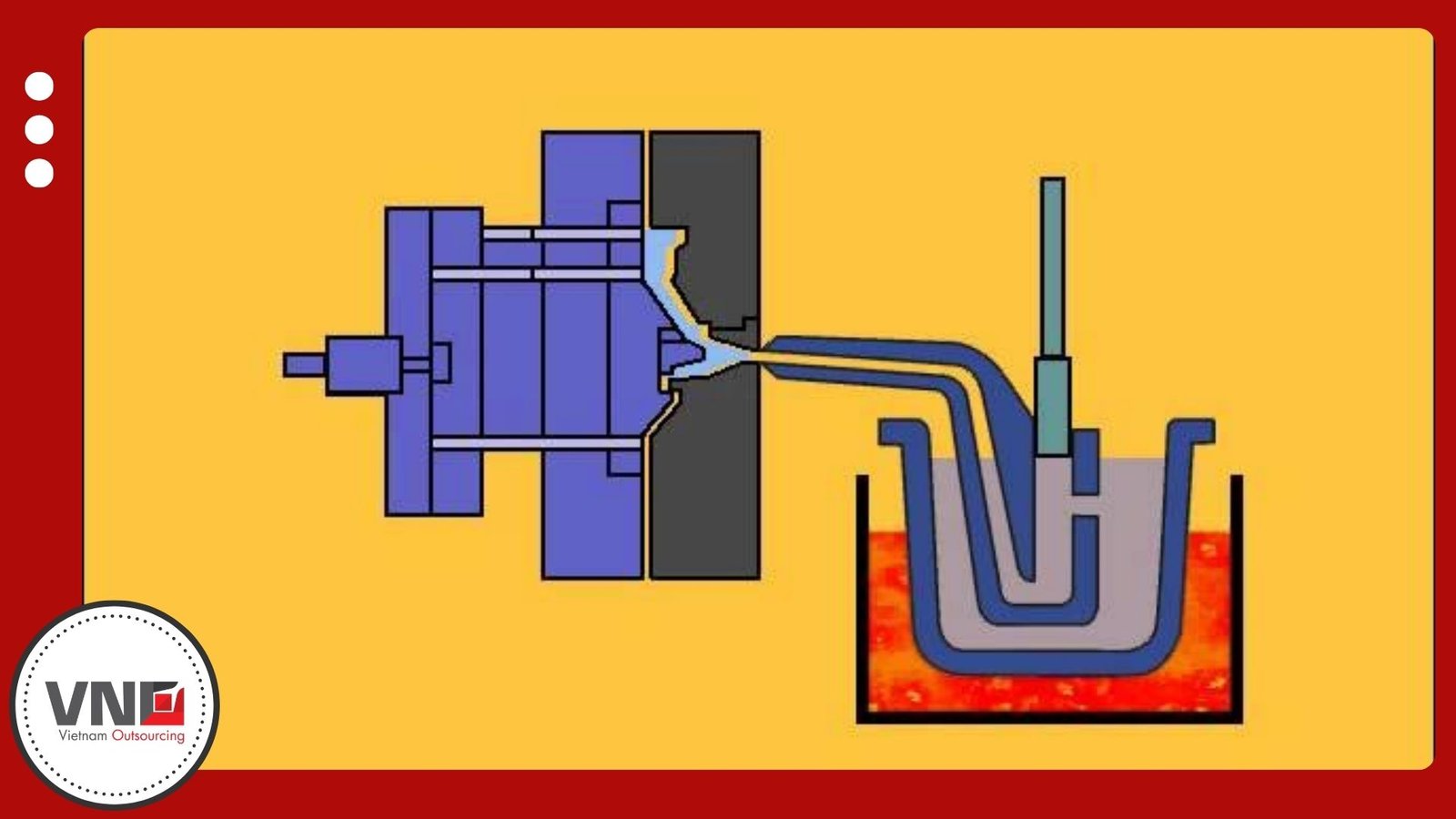

How a Hot Chamber Die Casting Machine Works

The operation of a hot chamber die casting machine includes four clear stages. Although similar to cold chamber casting, this process runs faster and more efficiently.

Stage 1: Mold Mounting and Clamping

Operators mount the mold on the machine and lock both halves tightly using the clamping mechanism. During this stage, the furnace keeps the molten metal ready for injection.

Stage 2: Metal Injection

The piston pushes molten metal directly from the furnace into the mold cavity. Because of the applied high pressure, the liquid metal quickly takes the exact shape of the mold, forming the required casting.

Stage 3: Mold Opening

After the metal solidifies, the movable half of the mold opens through the opening mechanism. At the same time, side cores retract, and the casting remains in the stationary half.

Stage 4: Product Ejection

The ejector system pushes the casting out of the mold. Once the product is removed, the mold closes again. The plunger then returns to the furnace, preparing the machine for the next cycle.

Advantages of Hot Chamber Die Casting Machines

-

Fast cycle times, which make them ideal for high-volume production.

-

Efficiency for small to medium-sized parts, reducing lead time.

-

Direct furnace connection, which minimizes handling of molten metal.

-

High precision and smooth surfaces, often eliminating extra finishing.

Conclusion

The hot chamber die casting machine remains essential for industries that demand precision and speed. It delivers accurate, cost-effective parts from alloys such as zinc, lead, and magnesium. Moreover, its short cycle times and reduced handling ensure consistent quality in large-scale production for both Western buyer and Vietnam die casting supplier.