- March 3, 2025

- Daniel Pham

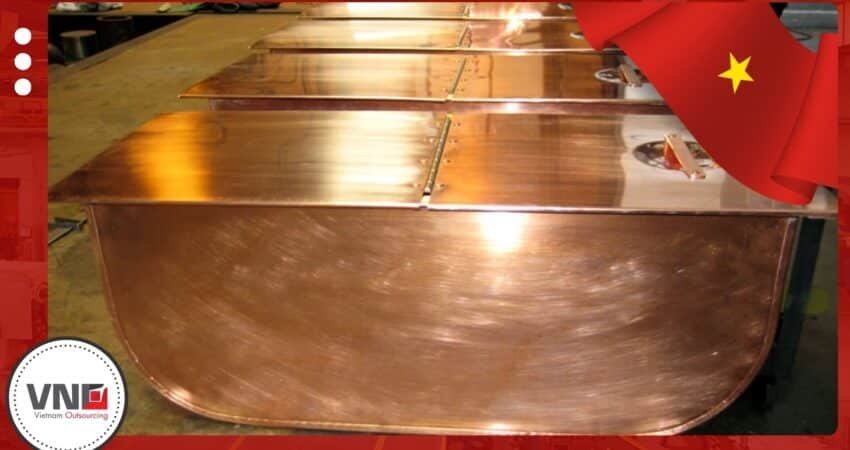

Forming Copper Sheet Metal in Vietnam

Table of Contents

Introduction: The Rising Demand for Copper Sheet Metal Forming

Forming copper sheet metal is essential for industries such as electronics, automotive, aerospace, and construction. Copper’s high conductivity, corrosion resistance, and malleability make it a preferred material for manufacturing components like electrical connectors, roofing sheets, and heat exchangers. However, rising production costs in China and India have led companies to seek more cost-effective alternatives. Vietnam is emerging as a strategic hub, offering affordable labor, advanced manufacturing capabilities, and strong trade agreements that benefit US and EU buyers.

Key Advantages

- Lower Manufacturing Costs: Competitive labor rates and efficient production reduce overall expenses for international buyers.

- High-Precision Metal Forming: Vietnamese factories utilize CNC machining, stamping, and hydroforming for precise and consistent results.

- Reliable Raw Material Supply: Vietnam has access to high-quality copper from domestic and regional suppliers.

- Favorable Trade Agreements: Free trade agreements (FTAs) provide tariff advantages for copper sheet exports.

Why Vietnam is a Competitive Hub for Forming Copper Sheet Metal

1. Cost-Effective Production and Skilled Workforce

Vietnam’s low labor costs and skilled workforce make it a viable alternative to China and India for copper sheet metal processing. Manufacturers benefit from a combination of affordability and technical expertise, ensuring efficient production.

2. Advanced Manufacturing Technologies

Vietnamese manufacturers invest in state-of-the-art CNC forming, stamping, and bending technologies, enabling:

- High-precision copper sheet metal forming for various industries.

- Custom solutions for specialized applications.

- Scalable production to meet global demand.

3. Reliable Supply Chain and Raw Material Sourcing

Vietnam’s strong network of copper suppliers and processing facilities ensures consistent quality and stable pricing for US and EU buyers.

Quality Assurance in Vietnam’s Copper Sheet Metal Forming Industry

Compliance With International Standards

Vietnamese manufacturers follow global quality certifications, such as:

- ISO 9001 – Ensuring a structured quality management system.

- ASTM Standards – Regulating copper sheet metal material and processing.

- IATF 16949 – Compliance for automotive applications.

Skilled Workforce and Continuous Training

Manufacturers invest in training programs to ensure their workforce stays updated on precision copper forming, bending, and stamping techniques.

Stringent Quality Control Measures

Factories conduct rigorous quality checks to guarantee precision and durability, including:

- Dimensional accuracy inspections.

- Material strength and corrosion resistance testing.

- Surface finish evaluations to prevent defects.

Vietnam’s Trade Agreements and Their Benefits

1. Lower Tariffs Through Free Trade Agreements

Vietnam’s trade policies give international buyers a pricing advantage:

- EU-Vietnam Free Trade Agreement (EVFTA): Reduces tariffs on copper exports to the EU.

- Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP): Expands trade with Canada, Japan, and Australia.

- Regional Comprehensive Economic Partnership (RCEP): Strengthens trade networks within Asia-Pacific.

2. Government Support for Metal Manufacturing

Vietnam’s government actively promotes foreign investment in the metal industry through:

- Tax incentives for manufacturers.

- Infrastructure development to support logistics and supply chains.

- Encouragement of advanced metal fabrication technology.

Challenges in Sourcing Copper Sheet Metal Forming from Vietnam

Logistics and Shipping Considerations

Although Vietnam offers cost savings, buyers should consider shipping times and logistics. Typically:

- Sea freight takes three to six weeks to reach US and EU markets.

- Airfreight is faster but at a higher cost for urgent shipments.

Ensuring Manufacturer Reliability

Selecting the right copper sheet metal processing supplier is critical. Buyers should:

- Conduct factory audits to verify capabilities.

- Review certifications to ensure industry compliance.

- Request sample testing to confirm material quality and forming precision.

Navigating Trade Compliance

Different countries have specific import/export regulations for copper products. Working with a trusted sourcing partner like Vietnam Outsourcing Pte Ltd helps buyers handle customs clearance, documentation, and regulatory compliance efficiently.

FAQs: Forming Copper Sheet Metal in Vietnam

- Why is Vietnam a cost-effective choice? Vietnam offers lower labor costs, high-quality materials, and efficient production compared to China and India.

- Can Vietnamese manufacturers handle large-scale copper sheet metal processing? Yes, many factories specialize in high-volume production while maintaining strict quality control.

- Are Vietnamese copper sheet manufacturers certified for international standards? Most reputable suppliers hold ISO, ASTM, and IATF 16949 certifications for compliance.

- What are the typical shipping times from Vietnam to the US or EU? Sea freight takes approximately three to six weeks, while airfreight is faster but more expensive.

- How can I ensure quality when outsourcing copper sheet metal forming? Partnering with Vietnam Outsourcing Pte Ltd ensures access to vetted manufacturers, quality inspections, and production oversight.

Conclusion

Vietnam’s low production costs, advanced technology, skilled workforce, and strong trade agreements make it a leading hub. As US and EU companies look for cost-effective and high-quality metal forming solutions, Vietnam is positioning itself as a reliable and competitive alternative to China and India.

You might also want to know more about spin forming