- April 1, 2024

- Daniel Pham

Introduction

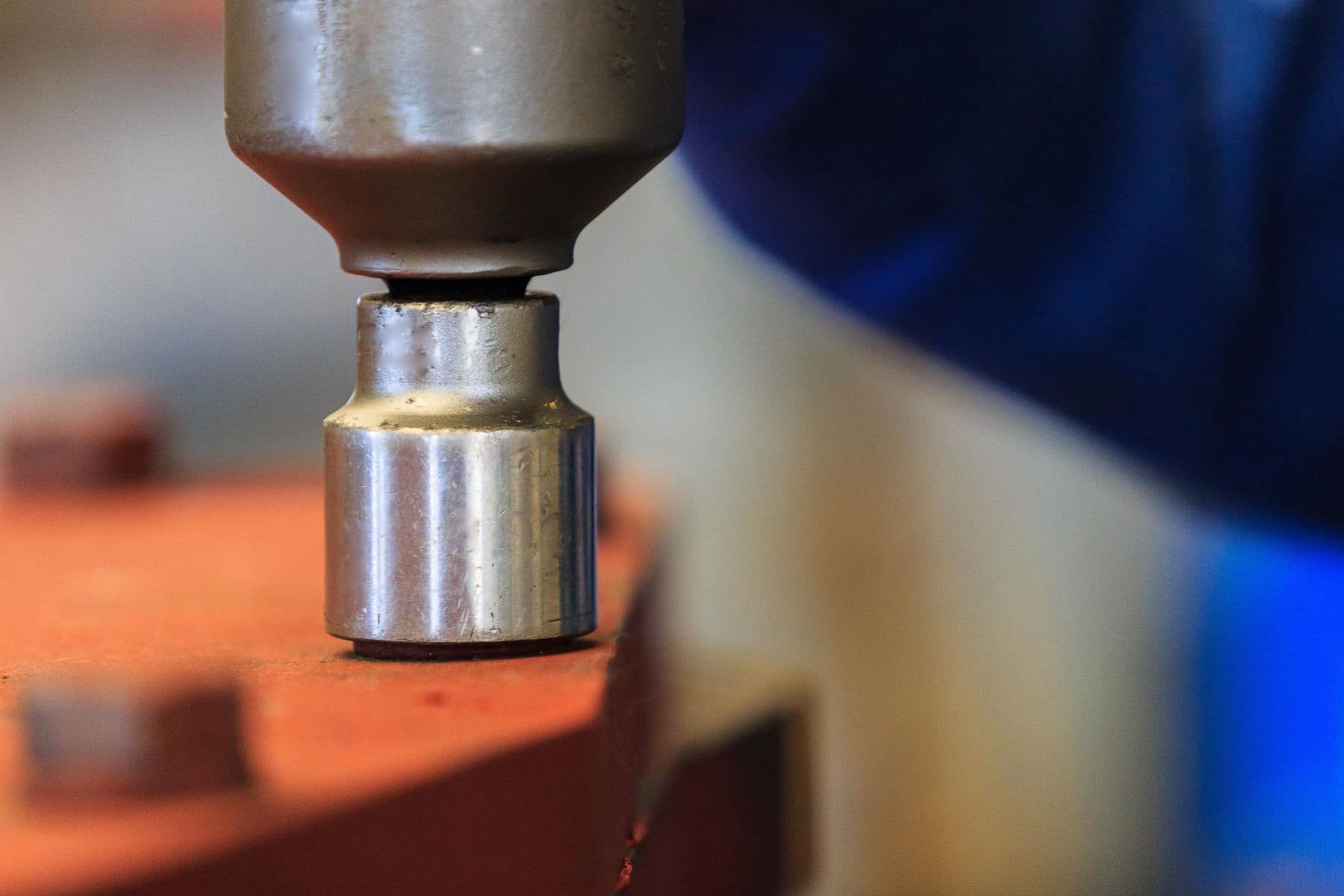

Welcome to an exploration of Torque Wrench Outsourcing and why Vietnam is becoming a global hub for this precision-driven industry. Torque wrenches are essential tools used to apply accurate force when tightening bolts and fasteners. Available in click, beam, digital, and hydraulic types, they are indispensable across industries where safety and precision matter most.

Overview of Torque Wrenches

Torque wrenches ensure that bolts and nuts are tightened exactly to manufacturer specifications. By preventing under- or over-tightening, they reduce risks of equipment failure, costly repairs, or safety hazards. As a result, they play a vital role not only in engineering and mechanics but also in industries such as aerospace, automotive, and construction.

Importance of Torque Wrenches in Industry

From assembling vehicles to maintaining aircraft, torque wrenches protect critical connections. In automotive manufacturing, they keep engines, brakes, and suspension systems safe and reliable. In aerospace, they guarantee that aircraft components perform under high stress. Even bicycle repair shops depend on torque wrenches to keep riders safe.

Outsourcing in Vietnam

The Rising Trend

In recent years, Vietnam has gained global attention as a prime destination for outsourcing. Companies see its fast-growing economy, skilled workforce, and strategic location as strong advantages. Moreover, its stable political environment and favorable trade policies make it an attractive alternative to traditional manufacturing hubs like China.

Benefits of Outsourcing to Vietnam

The benefits of Torque Wrench Outsourcing to Vietnam are clear:

-

Lower production costs due to affordable labor.

-

Skilled technical workforce with strong training in precision engineering.

-

Quality manufacturing practices aligned with global standards.

-

Strategic logistics location for exports to the US, EU, and Asia.

This mix of affordability and quality makes Vietnam one of the most competitive outsourcing destinations today.

Expertise in Torque Wrench Production

Skilled Workforce

Vietnam’s labor force is young, well-trained, and detail-oriented. Workers excel in precision tasks, making them ideal for torque wrench production. Technical training programs and vocational schools continue to expand, ensuring a steady pipeline of skilled engineers and technicians.

Precision Engineering Culture

Vietnam has built a reputation in precision engineering and metal forming production. Many factories specialize in producing high-accuracy tools like torque wrenches. Years of hands-on experience, supported by international certifications, ensure consistent results. This culture of precision is why outsourcing to Vietnam delivers reliable performance.

Cost-Effectiveness of Torque Wrench Outsourcing

Lower Labor Costs

Labor costs in Vietnam are significantly lower than in Western countries. Companies reduce expenses while maintaining high standards. These savings can be reinvested into R&D, marketing, or global expansion.

Competitive Pricing with Quality

Vietnamese manufacturers not only keep costs low but also deliver high-quality torque wrenches that meet ISO standards. This balance of quality and affordability helps businesses stay competitive in global markets.

Quality Assurance and Standards

Adherence to Global Standards

Vietnamese manufacturers follow strict certifications such as ISO 9001. This ensures every torque wrench meets international benchmarks for accuracy and durability.

Rigorous Quality Control

Factories apply strict quality checks at each stage, from raw materials to final testing. Automated inspections and digital torque sensors enhance precision, reducing risks of defects before shipping.

Innovation and Technology in Vietnam

Advanced Machinery

Factories in Vietnam use modern CNC machines, automated assembly lines, and digital torque calibration tools. These investments guarantee precision and consistency across large production volumes.

Ongoing Research and Development

Vietnamese manufacturers continuously improve through R&D. They explore material innovations, ergonomic designs, and integration of smart sensors. Collaboration with universities and engineers drives future-ready solutions.

You might also want to know about Modern Farming Equipment

Logistics and Supply Chain

Strategic Location

Vietnam’s position in Southeast Asia offers direct access to global shipping routes. Its deep-water ports and proximity to Asian supply chains reduce transit times and costs.

Streamlined Supply Chain Solutions

With modern infrastructure and real-time tracking systems, Vietnam ensures timely delivery. Businesses benefit from reduced inventory holding costs and improved supply chain visibility.

Success Stories and Client Feedback

Many companies outsourcing torque wrench production to Vietnam report faster delivery, lower costs, and higher customer satisfaction. Testimonials highlight reliable quality, responsive communication, and strong collaboration with Vietnamese partners.

Impact on Business Growth

Torque Wrench Outsourcing to Vietnam is not just about saving costs. It fosters long-term partnerships, opens access to new markets, and accelerates growth. Companies that embrace outsourcing here gain flexibility and innovation opportunities that keep them ahead in competitive markets.

Conclusion

The case for Torque Wrench Outsourcing in Vietnam is strong. With skilled labor, cost advantages, advanced technology, and strict quality standards, Vietnam is becoming a top choice for global buyers. Outsourcing here provides a sustainable balance of affordability and excellence.

Ready to explore torque wrench outsourcing opportunities? Contact Vietnam Outsourcing (VNO) today for tailored solutions.