Introduction

Die cast metal is one of the most widely used manufacturing processes today. It allows the creation of complex shapes with high precision and excellent surface quality. Many everyday items—from toy cars to real automotive parts—are produced using die casting. Because the process often eliminates the need for extra polishing or machining, it is both efficient and cost-effective for mass production.

The Die Cast Metal Process

The process starts with the creation of a steel mold, also known as a die. This mold is mounted onto a die casting machine. Molten metal or alloy is then injected into the die under high pressure. Once solidified, the die is opened and the casting removed.

There are two main methods of injection: hot chamber and cold chamber.

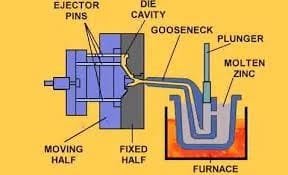

Hot Chamber Die Casting

Hot chamber machines keep the metal heated inside the machine. An oil or gas-powered plunger pushes molten metal into a gooseneck and then forces it into the mold cavity. The clamping force used in this process can range from 400 to 4000 tons. Because the injection cycle is short, production speeds are very high—sometimes only a few seconds for small parts. This method is commonly used for metals with low melting points such as zinc and magnesium.

Cold Chamber Die Casting

Cold chamber machines do not heat the metal directly. Instead, molten metal is poured into the chamber manually or by an automatic ladle. A hydraulic piston then forces the metal into the mold under high pressure. Although this method has slower cycle times compared to hot chamber systems, it is better suited for metals with higher melting points such as aluminum and copper alloys (take a look at how we do copper casting in Vietnam).

Advantages of Die Cast Metal

-

Provides high accuracy and dimensional stability.

-

Enables rapid production and short cycle times.

-

Allows thinner walls compared to investment casting (0.6 mm – 0.8 mm).

-

Produces a wide variety of shapes.

-

Simplifies assembly since outer threads and holes can be directly cast.

-

Offers smooth surface finishing (1 μm – 2.5 μm), often eliminating the need for extra polishing.

Disadvantages of Die Cast Metal

-

Casting size is limited to under 600 mm, with maximum wall thickness of about 13 mm.

-

High initial setup costs for molds and machines.

-

Requires large production volumes to remain cost-effective.

-

Porosity can occur due to pressure casting.

-

Restricted to metals with good fluidity, such as zinc, aluminum, magnesium, copper, lead, and tin.

Conclusion

Die cast metal remains one of the most efficient and versatile casting methods in modern manufacturing in general and for Vietnam die casting supplier in particular. It offers unmatched speed, accuracy, and surface quality for small to medium-sized components. Despite its limitations in size and initial cost, its ability to produce large volumes of consistent, high-quality parts makes it a cornerstone of industries such as automotive, consumer goods, and electronics.