Introduction

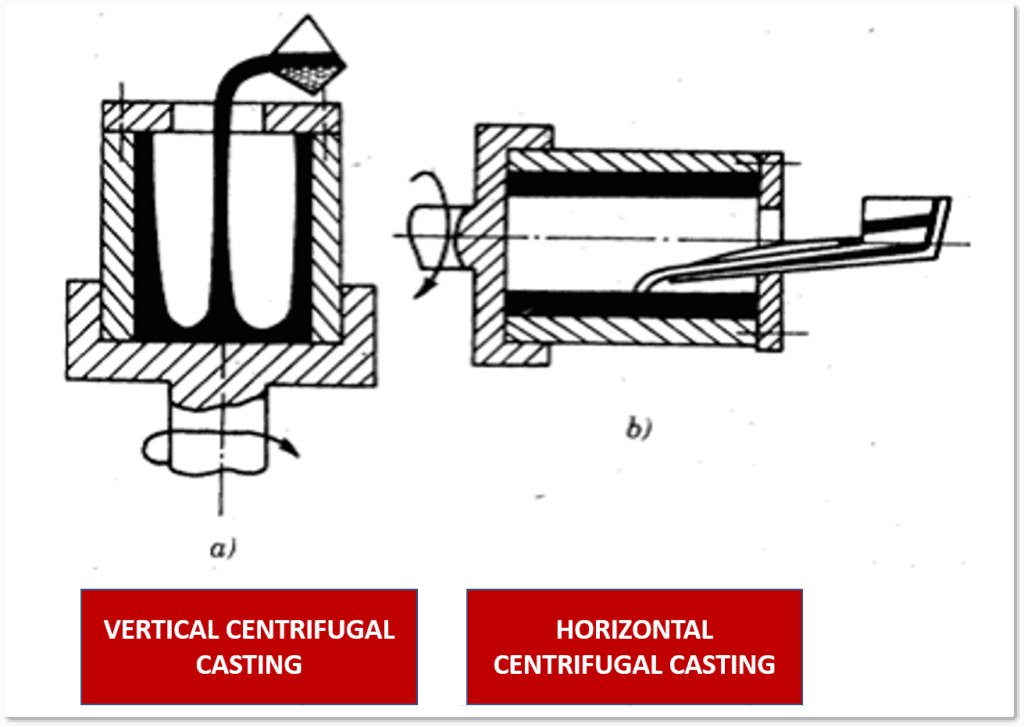

Centrifugal casting is a process where molten metal is poured into a rotating mold. As the mold spins, centrifugal force pushes the liquid metal outward. The alloy spreads evenly along the inner surface of the mold, solidifying into a dense and uniform casting. This method is especially effective for cylindrical or hollow components. You can also read more about advantage of die casting

Advantages of Centrifugal Casting

-

Produces a fine, dense metal structure with minimal gas porosity and shrinkage defects.

-

Uses no complex gating system, which reduces metal waste.

-

Allows the combination of different metals in a single casting.

-

Casts hollow circular parts without cores, saving both materials and labor.

-

Centrifugal force ensures excellent mold filling, making it possible to cast thin-walled, ribbed, or embossed shapes.

-

Requires no sprues, which further reduces metal consumption.

-

Produces cleaner castings, since impurities and slag with lower density are forced away from the metal during spinning.

Disadvantages of Centrifugal Casting

-

Different alloy elements may separate because each responds differently to centrifugal force.

-

When casting pipes, the internal diameter can be inaccurate and the inner surface rough.

-

Works best only for hollow, circular parts.

-

Molds must withstand both high temperatures and strong centrifugal forces, so they require high durability.

-

Controlling the exact inner diameter is difficult because it depends on the precise volume of molten metal poured.

-

Surfaces of rotating castings often show slag or impurities, which reduces surface quality.

-

The mold must rotate at high speed with perfect balance, which requires careful setup and strict control.

Applications of Centrifugal Casting

Because of its unique characteristics, centrifugal casting is widely applied across many industries. Vietnam die casting supplier uses it to produce pipes, rings, bushings, and cylindrical machine parts made from steel, cast iron, non-ferrous metals, and even nonmetals. Engineers often combine materials to enhance performance, such as casting an inner brass lining for wear resistance and an outer steel layer for strength and durability.