Introduction

The casting method in Vietnam reflects both the heritage of traditional craftsmanship and the progress of modern technology. From sand-clay molds used for centuries to advanced die casting and centrifugal systems, Vietnam has embraced multiple casting techniques to serve industries such as automotive, energy, shipbuilding, and aerospace.

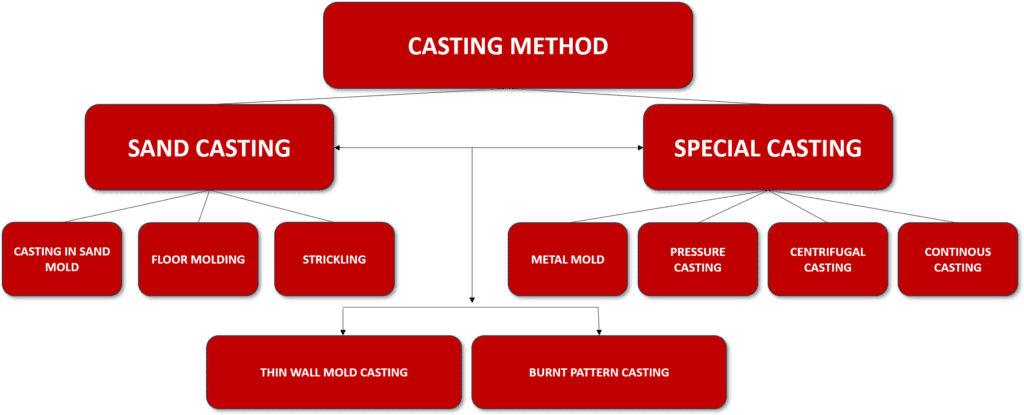

Casting remains a journey of continuous improvement. Each industrial revolution has brought innovations in materials, mold design, and solidification processes. Today, two main categories dominate: traditional sand casting and special casting methods.

Traditional Sand Casting

Sand casting, also called clay-sand casting, is the oldest and most widely used technique. In this method, sand mixed with clay creates a mold cavity. Molten metal is then poured in, left to cool, and finally removed once solidified.

Advantages of Sand Casting

- Low production cost

- Flexible and simple tooling

- Ability to cast large parts, from engine housings to industrial machine frames

Limitations

- Lower dimensional accuracy

- Rougher surface finish

- Higher risk of porosity and defects compared to advanced methods

Despite these limits, sand casting remains popular in Vietnam for heavy machinery, construction parts, popular sand casting products in the market and large-volume components.

Special Casting Methods in Vietnam

Special casting differs from ordinary sand casting in its material selection, molding technology, and filling methods. These processes often rely on metal molds and advanced solidification techniques.

Common Special Casting Methods

- Die Casting – high-pressure injection of molten metal, ideal for aluminum, zinc, and magnesium parts.

- Centrifugal Casting – spinning molds distribute molten metal, producing pipes, bearings, and bushings.

- Investment Casting – wax patterns coated with ceramic shells, used for complex and thin-walled parts.

- Gravity Casting – molten metal fills permanent molds by gravity, ensuring good strength and accuracy.

- Continuous Casting – production of billets, slabs, or rods with uniform properties.

- Vacuum Casting – removal of air during pouring, ensuring dense and defect-free castings.

Vietnamese foundries increasingly adopt these methods for aerospace components, turbine blades, ship propellers, and other high-performance applications.

Sand Casting vs Die Casting

| Feature | Sand Casting | Die Casting |

|---|---|---|

| Mold Type | Sand (disposable) | Metal (reusable) |

| Accuracy | Moderate | High |

| Surface Finish | Rougher | Smooth, precise |

| Part Size | Very large (tons) | Small to medium |

| Production Volume | Low to medium | High-volume mass production |

| Cost per Part | Low initial cost | Higher tooling cost, low per-part cost |

| Applications | Heavy machinery, shipbuilding, construction | Automotive parts, electronics, aerospace |

This comparison shows why both methods remain relevant. Sand casting offers flexibility and low setup cost, while die casting supports precision and large-scale production.

Casting Method in Vietnam: Industry Impact

Vietnam uses both sand and special casting methods to meet local and global demand. For example:

- Hydropower plants rely on turbine blades made through special casting.

- Shipyards order massive propellers cast using centrifugal and gravity casting.

- Aerospace and automotive sectors use die casting and investment casting for lightweight yet strong components.

By combining traditional techniques with modern innovations, Vietnam die casting supplier strengthens its role as a competitive player in global manufacturing.

Conclusion

The casting method in Vietnam demonstrates versatility and progress. Traditional sand casting continues to serve industries that need large, cost-effective parts, while special methods such as die casting, centrifugal casting, and investment casting deliver precision and performance for advanced sectors. Together, these approaches ensure Vietnam remains a strong player in the global casting industry.

Looking for reliable casting partners in Vietnam? Contact Vietnam Outsourcing (VNO) today to connect with qualified suppliers.