Overview of C Frame Hydraulic Presses

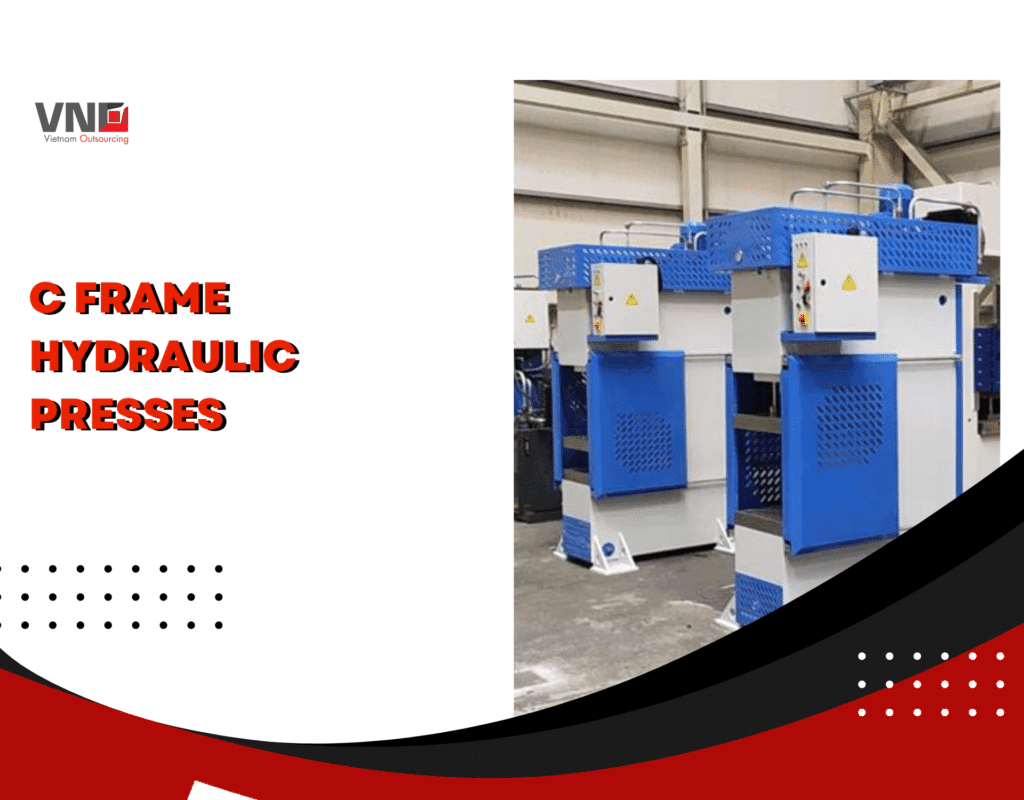

Featuring a distinctive C-shaped structure, C Frame Hydraulic Presses provide excellent access to the working area from three sides. This open-front design makes it easier to load materials, change tools, and perform maintenance.

The compact yet robust construction ensures stability and precision during operations. Moreover, the frame minimizes deflection and enhances force application, guaranteeing consistent performance across different tasks. As a result, these presses are highly valued in industries that demand accuracy and flexibility.

Key Applications and Benefits

Punching Operations

In punching, C Frame presses deliver steady and accurate force. This consistency ensures clean holes in various materials. The open design helps operators position workpieces with precision, which improves product quality.

Bending Applications

For bending, these presses apply controlled force while maintaining accuracy. This is crucial in sectors like automotive and aerospace, where components must meet tight tolerances. In addition, their flexibility allows them to adapt to diverse bending tasks.

Assembly Processes

The accessibility of a C Frame press is especially useful in assembly. Operators can align and fit parts more efficiently, reducing cycle times and boosting productivity. Furthermore, the compact footprint saves workshop space without compromising performance.

Case Studies of C Frame Hydraulic Presses in Vietnam

Electronics Manufacturing

An electronics manufacturer integrated C Frame Hydraulic Presses from Vietnam into its production line. These presses, compliant with ISO 9001:2015, increased efficiency by 25% and reduced defect rates significantly.

Automotive Industry

A Vietnamese supplier partnered with a global automotive company to provide C Frame presses for assembly tasks. Their precision and accessibility improved production accuracy, while CE marking and EN 693 compliance confirmed international quality standards.

Metal Fabrication

A fabrication firm adopted Vietnamese-made C Frame presses for custom bending projects. Over three years, they achieved a 30% rise in production capacity and cut material waste by 20%. This success highlighted both cost savings and quality gains.

Why Source C Frame Hydraulic Presses from Vietnam?

Vietnam offers several advantages for global buyers:

Accuracy and Reliability – Machines achieve tolerances within ±0.1 mm.

Competitive Costs – Up to 30% savings compared to other sourcing regions.

Customization – Tailored designs to meet unique production needs.

Compliance – Factories meet ISO, CE, and EN standards.

Technical Support – Suppliers provide consultation, setup, and after-sales service.

Consequently, Vietnam has become a trusted hub for sourcing C Frame Hydraulic Presses, combining advanced design, affordability, and strict quality control. You might also want to know about H Frame Hydraulic Presses

Conclusion

C Frame Hydraulic Presses offer unmatched accessibility, precision, and operational ease. From electronics to automotive and metal fabrication, they prove invaluable in industries requiring accuracy and efficiency.

Looking for high-quality C Frame Hydraulic Presses? Contact Vietnam Outsourcing (VNO) today for tailored solutions that enhance productivity and reduce costs.