- September 11, 2025

- Daniel Pham

Battery Housing Outsourcing in Vietnam

Table of Contents

Introduction

As the global electric vehicle (EV) and energy storage markets expand, the demand for durable, lightweight, and safe battery enclosures is rising. Companies are increasingly turning to battery housing outsourcing in Vietnam to balance cost efficiency, innovation, and international compliance.

Vietnam is building a strong reputation as a hub for precision manufacturing, with specialized battery housing factories equipped to serve industries such as EVs, renewable energy, and consumer electronics. By outsourcing to a battery housing manufacturer in Vietnam, international buyers can secure competitive pricing while meeting demanding technical requirements. Client who is looking for Roofing outsourcing is also benefit for this.

Technology in Battery Housing Manufacturing

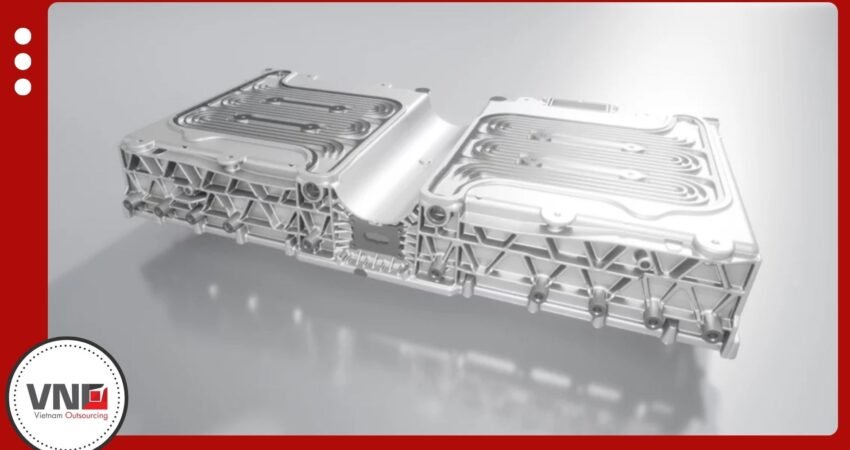

Battery housings are critical components that protect cells, ensure thermal stability, and maintain structural integrity under stress. To achieve these functions, battery housing factories in Vietnam employ advanced processes such as:

- Metal forming – stamping, deep drawing, or extrusion of aluminum and steel to create strong yet lightweight housings.

- CNC machining – precision drilling, milling, and slotting for connectors, fasteners, and cooling systems.

- Welding technologies – MIG/TIG welding, laser welding, and friction stir welding (FSW) for airtight, durable assembly.

- Surface treatments – anodizing, powder coating, or e-coating for corrosion resistance and thermal protection.

- Design customization – CAD/CAM integration for prototypes, custom geometries, and scalable mass production.

These capabilities enable suppliers of battery housing in Vietnam to produce enclosures that meet the highest international safety and performance standards.

For more Vietnam supplier capability, you can take a look at Sheet Metal Cutting in Vietnam

Quality Control in Battery Housing Outsourcing

Since battery housings are directly tied to the safety and performance of EVs and energy systems, quality control is non-negotiable. Trusted battery housing manufacturers in Vietnam apply rigorous standards, including:

- ISO 9001 and IATF 16949 certifications for automotive-grade manufacturing.

- Material testing for aluminum and steel strength, heat resistance, and corrosion protection.

- Dimensional inspections using CMM (Coordinate Measuring Machines) for accuracy.

- Leak testing and pressure resistance checks to ensure housings are sealed and safe.

- Crash and thermal simulations to verify compliance with global EV standards.

These quality control measures ensure buyers receive reliable products that comply with U.S., EU, and Asia-Pacific regulations.

Choosing the Right Partner

Not all suppliers offer the same expertise in battery housing outsourcing in Vietnam. When selecting a partner, buyers should evaluate:

- Technical capabilities – Does the factory have extrusion, stamping, and advanced welding capabilities?

- Certifications – Can they provide ISO, IATF, or UL certification for safety-critical components?

- Experience – Do they serve global EV or energy storage clients?

- Flexibility – Can they handle both prototypes and large-scale mass production?

- After-sales support – Do they offer testing reports, warranty, and traceability documentation?

A reliable partner not only delivers quality products but also reduces risks in supply chain management. You might also want to know more about Safety Anchor Outsourcing

Why Vietnam for Battery Housing Outsourcing?

Vietnam is becoming a strong alternative to China and India in the global supply chain. For battery housing outsourcing in Vietnam, the country offers several advantages:

- Cost efficiency – Lower labor costs and competitive raw material sourcing.

- Skilled workforce – Young engineers trained in advanced machining and welding.

- Modern infrastructure – Factories with CNC machines, extrusion lines, and galvanizing facilities.

- Trade agreements – FTAs with the U.S., EU, and Asia-Pacific markets reduce tariffs and simplify logistics.

- Growing EV ecosystem – Vietnam is investing in EVs and renewable energy, driving local expertise in battery housing manufacturing.

These strengths make Vietnam one of the fastest-growing outsourcing destinations for EV and energy storage components.

Vietnam Outsourcing: Your Trusted Partner

At Vietnam Outsourcing (VNO), we connect global buyers with certified battery housing factories across Vietnam. Our services include:

- Supplier vetting to ensure compliance with international quality standards.

- Local engineering teams to oversee production and provide technical support.

- Independent quality inspections before shipment.

- Expertise in managing OEM and customized battery housing projects.

- Proven experience serving U.S. and EU clients with precision components.

By working with VNO, buyers gain access to trusted battery housing manufacturers in Vietnam, minimizing risks while maximizing cost savings and quality assurance.

Conclusion

As demand for EVs and energy storage solutions continues to rise, outsourcing battery housing production has become a strategic move for global manufacturers. Battery housing outsourcing in Vietnam offers the right combination of affordability, quality, and reliability.

With advanced technology, strict quality control, and international trade access, battery housing factories in Vietnam are ready to meet global demand. Partnering with Vietnam Outsourcing (VNO) ensures buyers gain not just a supplier, but a long-term partner in the global energy transition.

Looking for a reliable battery housing supplier in Vietnam? Contact Vietnam Outsourcing (VNO) today for certified manufacturing solutions tailored to your project needs.