- September 8, 2025

- Daniel Pham

Aluminum Welding in Vietnam: Process, Techniques, and Applications

Table of Contents

What is Aluminum Welding?

Aluminum welding is the process of joining aluminum parts such as pipes, tanks, and structural components using heat and pressure. Unlike steel, aluminum conducts heat quickly and requires specialized equipment, protective gases, and skilled techniques to achieve strong results. Because the process prevents oxidation and ensures durability, aluminum welding delivers reliable performance in demanding applications.

In Vietnam, manufacturers increasingly adopt advanced aluminum welding techniques to serve industries such as automotive, aerospace, construction, and marine. With competitive costs and international certifications, Vietnam has become an attractive hub for global buyers seeking high-quality welding services.

Aluminum: A Versatile Material

Aluminum is one of the most widely used metals in the modern economy. It is lightweight, affordable, and easy to machine, which makes it valuable in diverse applications. For instance, manufacturers use aluminum in beverage cans, cookware, building materials, and automotive parts. Moreover, aluminum alloys improve strength and corrosion resistance, giving industries a cost-effective yet durable option for production.

Types of Aluminum Welding Processes

Several welding processes are suitable for aluminum, each with specific benefits:

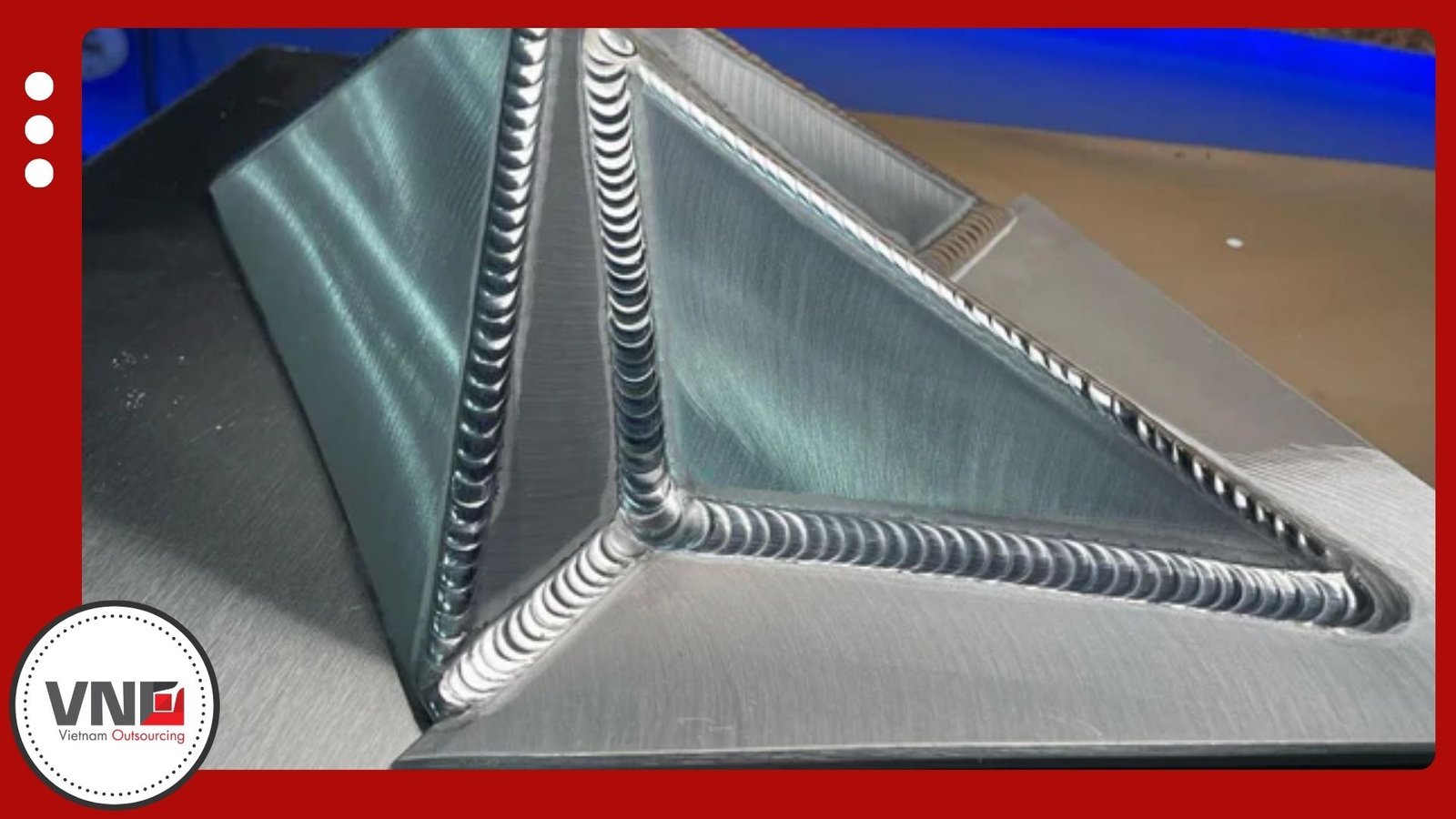

- TIG Welding (GTAW) – Provides precise welds and is ideal for thin materials and high-quality joints.

- MIG Welding (GMAW) – Uses a continuous wire electrode and shielding gas, perfect for thicker aluminum and faster production.

- Flux-Cored Arc Welding (FCAW) – Works well outdoors since it relies on flux for protection.

- Shielded Metal Arc Welding (SMAW) – Also known as stick welding, often used for repairs or structural parts.

- Submerged Arc Welding (SAW) – Delivers deep penetration and is used in heavy-duty applications.

Among these techniques, TIG welding remains the most popular for aluminum because it produces clean, accurate welds with minimal contamination.

How to Weld Aluminum: Step by Step

- Surface Preparation – Clean both aluminum surfaces with sandpaper or wire brushes to remove oxides.

- Apply Flux – Coat the joint with flux to strengthen the bond and prevent oxidation.

- Preheat the Material – Preheating stabilizes temperature and reduces the risk of cracking.

- Begin Welding – Use TIG, MIG, or another appropriate process, keeping the torch steady to avoid burn-through.

- Cooling Phase – Allow the weld to cool gradually; controlled cooling improves structural integrity.

- Finishing Touches – Grind away excess material, clean the joint, and test the weld for strength and quality.

By following these steps, welders achieve consistent and durable results. Vietnamese factories often use automated welding systems, which further enhance precision and repeatability.

Key Techniques in Aluminum Welding

Electrode Selection

Tungsten electrodes with rounded tips are most effective for aluminum alloys. To ensure arc stability, welders typically extend the electrode about 3.2 mm from the torch.

Protective Gas

Pure argon gas is the most common shielding gas for aluminum welding due to its strong cleaning properties. In certain cases, a helium-argon mix provides deeper penetration and reduces magnesium oxide buildup.

Arc Control

High-frequency AC or DC currents allow welders to start arcs without direct electrode contact. Once the arc forms, maintaining an arc length around 1.5 times the electrode diameter ensures optimal penetration.

Torch Angle and Movement

For butt welds, a 90-degree angle is standard. However, welders often tilt the torch at approximately 60 degrees in the welding direction. If the sheets differ in thickness, the torch is angled slightly toward the thicker piece to balance the heat.

Speed and Heat

Because aluminum transfers heat quickly, welders must apply higher voltage and current than when working with steel. Moving the torch too slowly can cause burn-through, especially with thinner parts. Therefore, aluminum welding requires a “hot and fast” approach.

Aluminum Welding in Vietnam: Industry Strengths

Vietnam has developed into a competitive hub for aluminum welding thanks to its skilled workforce, modern equipment, and cost advantages. Local factories invest in advanced welding systems from Germany, Japan, and the U.S., ensuring compliance with ISO and AWS standards.

Key strengths of aluminum welding in Vietnam include:

- Cost efficiency – Lower labor and production costs compared to Western markets and even China.

- Technical expertise – Welders are trained in both manual and robotic welding techniques.

- Advanced facilities – Access to TIG, MIG, automated welding lines, and integrated finishing processes.

- Global supply readiness – Reliable shipping networks that serve U.S. and EU buyers consistently.

At Vietnam Outsourcing (VNO), we connect international clients with top Vietnamese suppliers offering aluminum welding services. Our engineering team supervises quality control and ensures that every project meets technical specifications and international standards. By partnering with VNO, buyers reduce risks, save costs, and gain access to Vietnam’s fast-growing industrial base. For deep insight of Vietnamese market, you might want to read aluminum manufacturing in Vietnam