Introduction

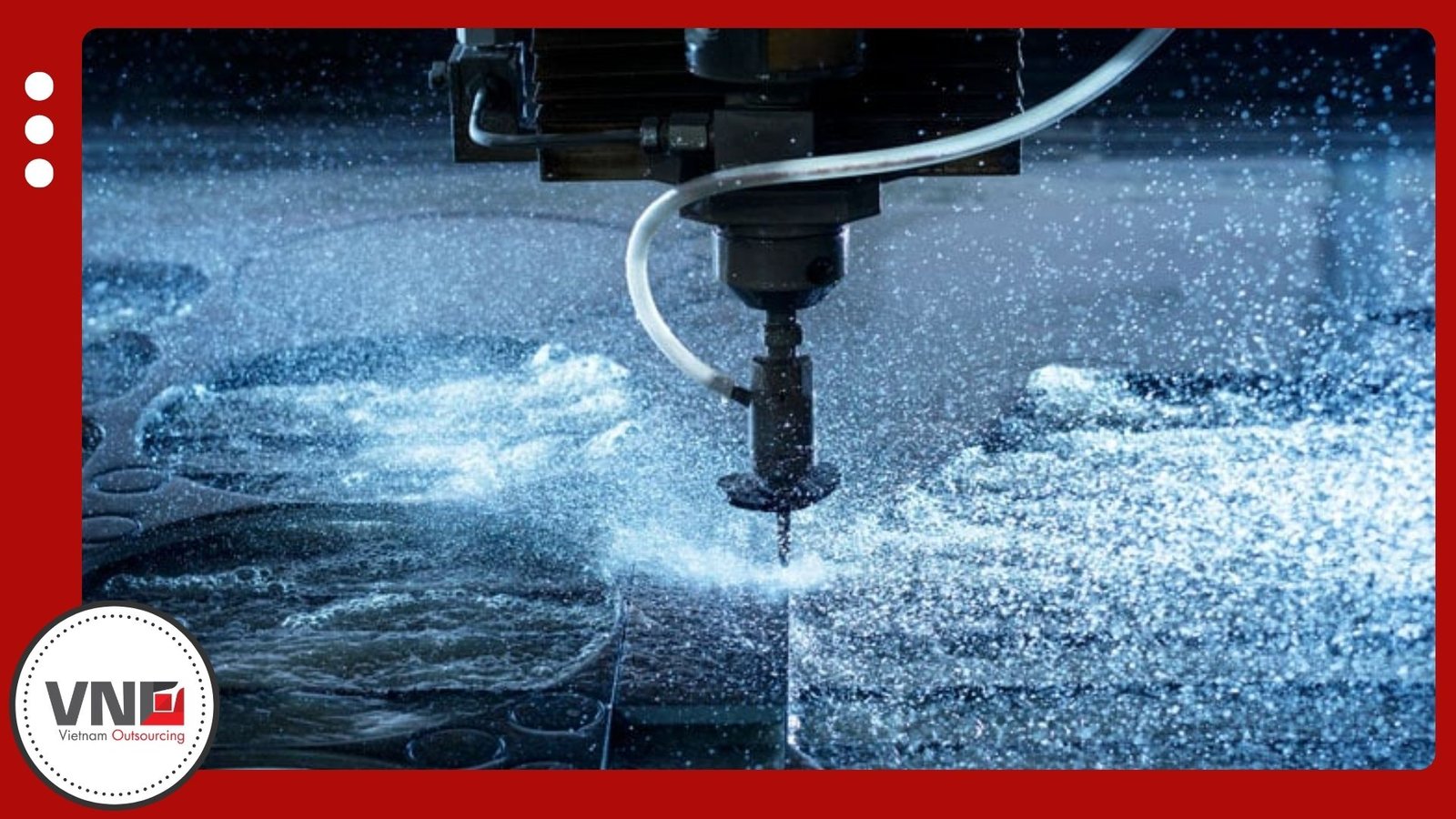

Abrasive water jet machining (AWJM) is one of the most versatile and modern cutting technologies available today. Initially, water jet systems were limited to cutting soft, low-hardness materials such as rubber, textiles, or plastics. However, with the introduction of abrasive particles into the water stream, this method evolved into a powerful machining tool capable of cutting virtually any material, from metals to composites.

Today, AWJM is used in more than 50 industries worldwide, including aerospace, automotive, medical devices, and construction. Its ability to cut without generating heat, combined with its precision and flexibility, makes it a key technology in advanced manufacturing.

Development of Abrasive Water Jet Machining

The transition from conventional water jet cutting to abrasive water jet machining began with the challenge of processing harder materials. By injecting abrasive particles such as garnet into the high-pressure water stream, manufacturers achieved cutting speeds and forces strong enough to slice through metals, ceramics, and even composites.

Furthermore, a major innovation was the development of ceramic carbide composite tubes, which extended the lifespan of nozzles exposed to high pressure and abrasive wear. As a result, AWJM became more reliable and economical, paving the way for its adoption across global industries.

Conventional Water Jet Machining vs. Abrasive Water Jet Machining

There are clear distinctions between the two methods:

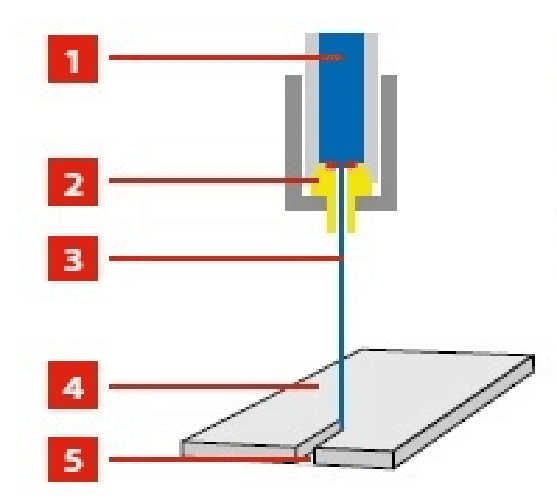

Conventional water jet machining:

- Uses only high-pressure water.

- Best suited for soft materials like paper, rubber, plastics, textiles, and food products.

- Provides clean cuts without heat, but it is limited in material range.

- 1 – High pressure water

- 2 – Nozzle

- 3 – Waterjet beam

- 4 – Workpiece

- 5 – Cut width

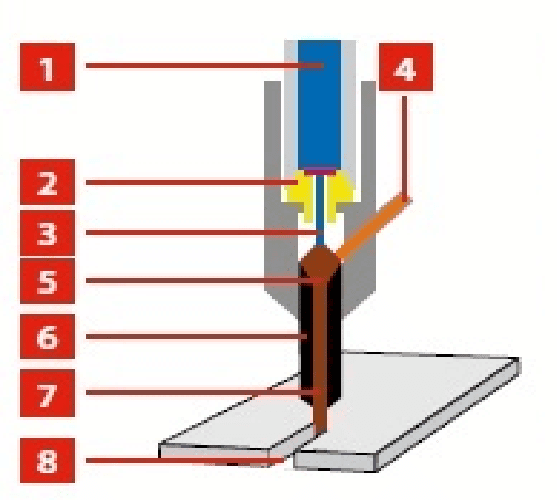

Abrasive water jet machining:

- Introduces abrasive particles (commonly garnet) into the water stream.

- Capable of cutting hard materials such as steel, aluminum, glass, ceramics, and composites.

- Offers higher precision and can process thicknesses that other cutting methods struggle with.

- 1 – High pressure water

- 2 – Nozzle

- 3 – Waterjet beam

- 4 – Abrasive loader (non-pressure)

- 5 – Mixing tube (vacuum tube)

- 7 – Water with abrasive particle nozzle

- 8. Cut width

In short, AWJM extends the capability of conventional systems, making it applicable in industries where strength, accuracy, and material diversity are essential.

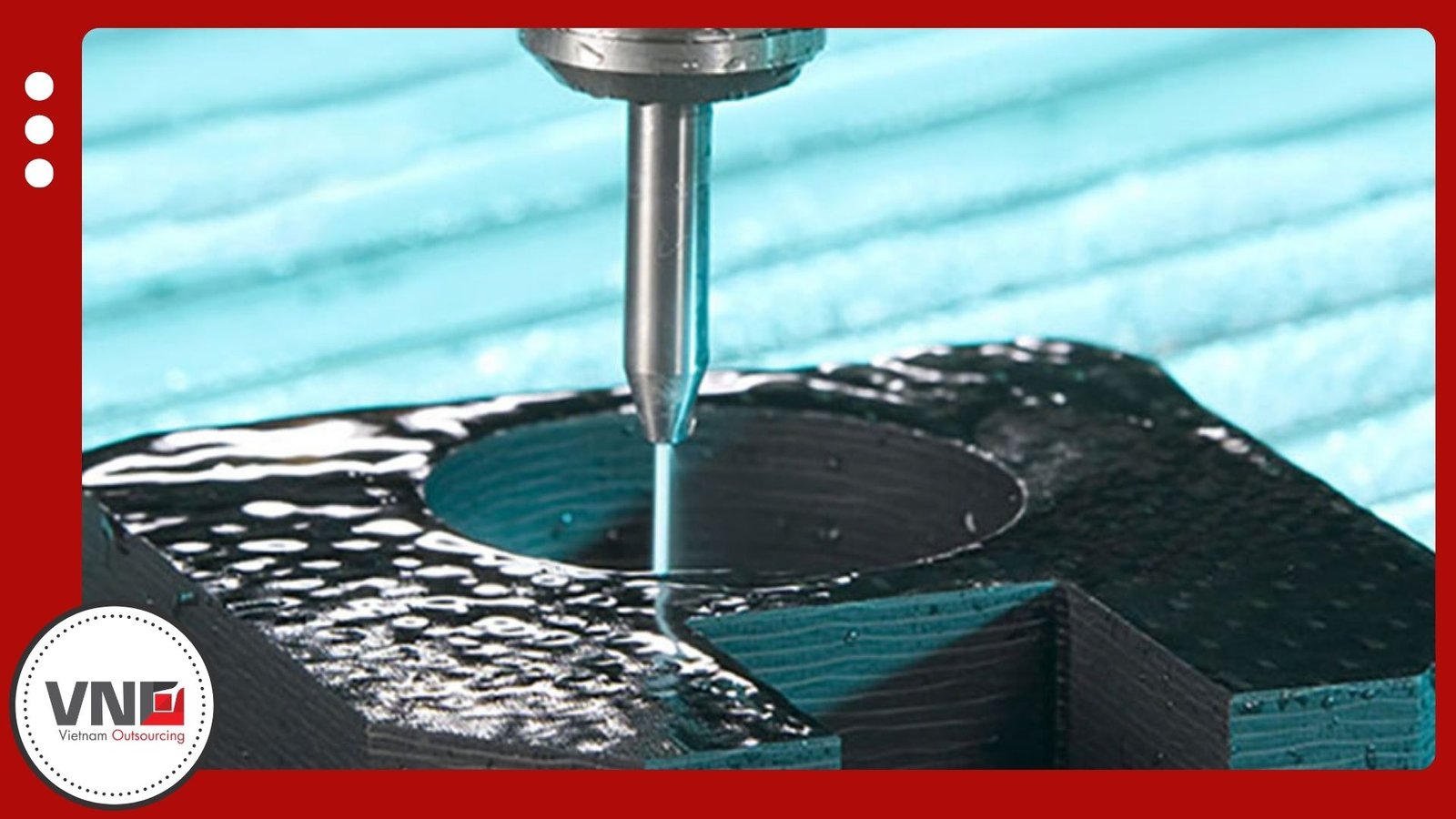

How Abrasive Water Jet Machining Works

The AWJM process involves several key stages:

- High-pressure generation: A pump creates extremely high water pressure, often exceeding 4,000 bar (60,000 psi). Two types of pumps are commonly used:

- Direct drive pumps – simpler design, suited for lower to medium pressure.

- Intensifier pumps – use hydraulic systems to generate higher pressures for industrial cutting.

- Water acceleration: The pressurized water flows through high-pressure hoses to the nozzle.

- Nozzle focusing: Inside the nozzle, the water passes through a tiny orifice that converts pressure into velocity, producing a jet stream with speeds up to 2,736 km/h.

- Abrasive mixing: Abrasive particles (such as garnet) are introduced into the mixing chamber. These particles mix with the water jet, creating a high-energy cutting stream.

- Material cutting: The abrasive-laden jet exits the nozzle and impacts the workpiece, eroding the material with precision and leaving smooth, burr-free edges.

This cold-cutting process ensures no heat-affected zones, no material deformation, and no toxic fumes—advantages that make AWJM stand out from laser or plasma cutting.

Advances in Motion Control and Software

Early water jet systems relied on mechanical protractors or G-code-based NC systems. However, accuracy was limited, especially when cutting curves, arcs, or complex profiles.

In the early 1990s, software innovation transformed the field. The development of OMAX motion control systems allowed precise control of nozzle speed and positioning using standard PCs. This advancement improved accuracy in cutting complex shapes, enabling AWJM to produce components with tolerances comparable to other precision machining methods.

Applications of Abrasive Water Jet Machining

Because of its versatility, AWJM is used across multiple sectors:

- Aerospace: Cutting titanium and composite materials for aircraft parts.

- Automotive: Producing gears, brackets, and lightweight aluminum components.

- Construction: Shaping stone, glass, and tiles with intricate patterns.

- Medical: Manufacturing implants and surgical tools that require burr-free finishes.

- Electronics: Cutting composite circuit boards and enclosures without heat damage.

Its flexibility makes AWJM one of the few cutting technologies that can handle both soft and extremely hard materials with equal efficiency.

Conclusion

The development of abrasive water jet machining has revolutionized modern cutting technologies. From its origins in cutting soft materials to becoming a versatile solution for metals, ceramics, and composites, AWJM offers unmatched precision and flexibility.

By eliminating heat effects, reducing waste, and delivering smooth finishes, it continues to be a preferred choice in industries that demand accuracy and reliability. As software and nozzle technology evolve further, AWJM is set to remain a cornerstone of advanced manufacturing.

Interested in exploring AWJM solutions for your production needs? Contact Vietnam Outsourcing (VNO) today to connect with certified water jet machining suppliers.